Preparation method of feed for increasing fat utilization rate of tilapia

A utilization rate, tilapia technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problem that the tilapia cannot meet the nutritional needs of tilapia growth, affect the utilization rate of tilapia to feed, and adversely affect the health and safety of tilapia. Growth and other problems, to achieve the effect of improving tilapia fat utilization, protecting liver and intestinal health, and increasing water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

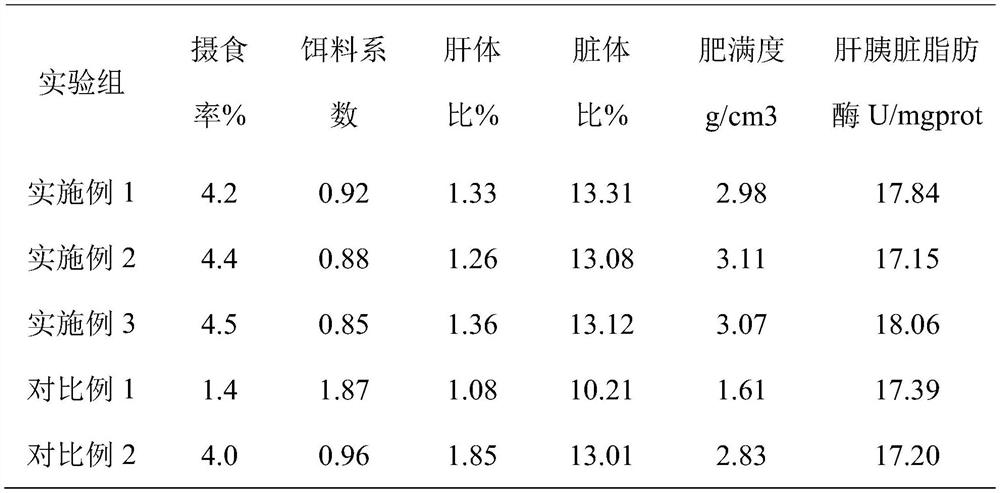

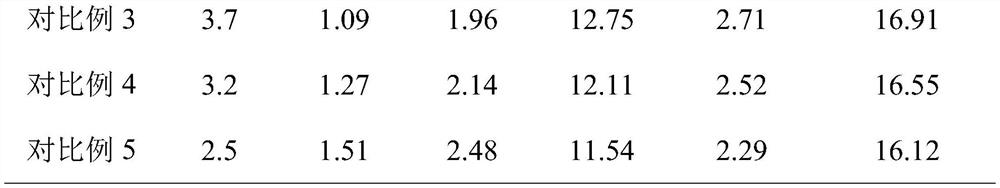

Examples

Embodiment 1

[0027] A preparation method for improving the fat utilization rate of tilapia feed, comprising the steps of:

[0028] S1. Weigh the following raw materials in parts by weight: 10 parts of corn, 10 parts of wheat, 20 parts of soybean meal, 8 parts of cottonseed meal, 8 parts of peanut cake, 3 parts of rice bran, 0.2 part of trehalose, 3 parts of fish oil, 1.8 parts of calcium hydrogen phosphate 0.3 parts of fish multivitamin, 0.05 parts of glyceryl monostearate, 2 parts of soybean lecithin oil, 0.4 parts of glycerin, 0.1 parts of tannic acid, 0.1 parts of ethyl maltol, 2 parts of wheat germ fermentation powder, spirulina 1 part of baking powder and 0.02 part of chitosan oligosaccharide;

[0029] S2. According to the formula ratio, take corn, wheat, soybean meal, cottonseed meal, peanut cake and rice bran, mix and coarsely pulverize, add trehalose, mix and stir evenly, carry out secondary pulverization to pass through 180 mesh, and obtain the mixed material;

[0030] S3. After ...

Embodiment 2

[0035] A preparation method for improving the fat utilization rate of tilapia feed, comprising the steps of:

[0036] S1. Weigh the following raw materials in parts by weight: 15 parts of corn, 15 parts of wheat, 30 parts of soybean meal, 15 parts of cottonseed meal, 10 parts of peanut cake, 5 parts of rice bran, 0.3 part of trehalose, 5 parts of fish oil, 2.2 parts of calcium hydrogen phosphate 0.4 parts of fish multivitamin, 0.08 parts of glyceryl monostearate, 4 parts of soybean lecithin oil, 0.6 parts of glycerin, 0.2 parts of tannic acid, 0.2 parts of ethyl maltol, 3 parts of wheat germ fermentation powder, spirulina 2 parts of baking powder and 0.03 part of chitosan oligosaccharide;

[0037] S2. According to the formula ratio, take corn, wheat, soybean meal, cottonseed meal, peanut cake and rice bran, mix and coarsely pulverize, add trehalose, mix and stir evenly, carry out secondary pulverization to pass 200 mesh, and obtain the mixed material;

[0038] S3. After stirr...

Embodiment 3

[0043] A preparation method for improving the fat utilization rate of tilapia feed, comprising the steps of:

[0044] S1. Weigh the following raw materials in parts by weight: 12 parts of corn, 12 parts of wheat, 25 parts of soybean meal, 10 parts of cottonseed meal, 9 parts of peanut cake, 4 parts of rice bran, 0.25 part of trehalose, 4 parts of fish oil, 2 parts of calcium hydrogen phosphate 0.35 parts of fish multivitamin, 0.06 parts of glyceryl monostearate, 3 parts of soybean lecithin oil, 0.5 parts of glycerin, 0.15 parts of tannic acid, 0.15 parts of ethyl maltol, 2.5 parts of wheat germ fermentation powder, spirulina 1.5 parts of baking powder and 0.03 parts of chitosan oligosaccharide;

[0045]S2. According to the formula ratio, take corn, wheat, soybean meal, cottonseed meal, peanut cake and rice bran, mix and coarsely pulverize, add trehalose, mix and stir evenly, carry out secondary pulverization to pass 200 mesh, and obtain the mixed material;

[0046] S3. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com