Preparation method and application of coffee-flavor type essence and perfume

A technology for flavors, fragrances and flavors, which is applied in the field of preparation of coffee flavors and flavors, and can solve the problems of heavy miscellaneous gas, high combustion temperature, poor oral comfort and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

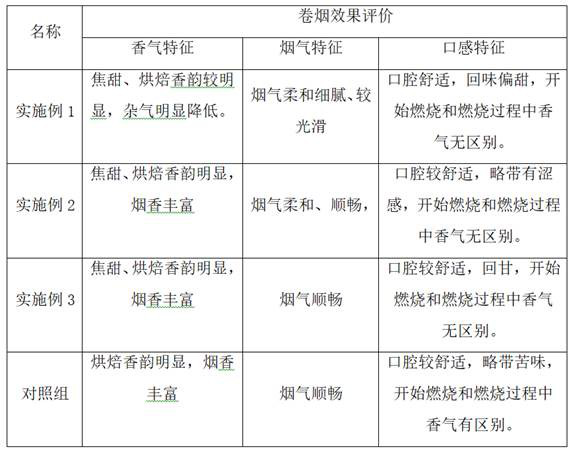

Examples

Embodiment 1

[0046]A method for preparing a coffee-flavored flavor and fragrance, comprising the steps of mixing the components of the interior flavor and mixing the components of the surface flavor, and the lining flavor includes the following components in parts by weight:

[0047] Brazilian coffee extract 10 parts

[0048] Tobacco extract 25 parts

[0049] Maple extract 3 parts

[0050] L-menthone 1 part

[0051] Fenugreek Extract 10 parts

[0052] Licorice Maillard reactant 5 parts

[0053] Solvent 10 parts

[0054] Wherein, the tobacco extract includes any one or several mixtures of Yunyan extract, Brazilian tobacco extract, and Zimbabwean tobacco leaf extract; the licorice Maillard reactant is a product independently prepared by the company, and the solvent is pure The mixture of water and propylene glycol, and other fragrance raw materials are commercially available products.

[0055] Described table fragrance essence comprises following component by weight part:

[0056] Eth...

Embodiment 2

[0080] A method for preparing a coffee-flavored flavor and fragrance, comprising the steps of mixing the components of the interior flavor and mixing the components of the surface flavor, and the lining flavor includes the following components in parts by weight:

[0081] Brazilian coffee extract 20 parts

[0082] Tobacco extract 30 parts

[0083] Maple maple extract 5 parts

[0084] L-menthone 5 parts

[0085] Fenugreek Extract 20 parts

[0086] Licorice Maillard reactant 10 parts

[0087] Solvent 45 parts

[0088] Wherein, the tobacco extract includes any one or several mixtures of Yunyan extract, Brazilian tobacco extract, and Zimbabwean tobacco leaf extract; the licorice Maillard reactant is a product independently prepared by the company, and the solvent is pure The mixture of water and propylene glycol, and other fragrance raw materials are commercially available products.

[0089] Described table fragrance essence comprises following component by weight part:

[...

Embodiment 3

[0113] A method for preparing a coffee-flavored flavor and fragrance, comprising the steps of mixing the components of the interior flavor and mixing the components of the surface flavor, and the lining flavor includes the following components in parts by weight:

[0114] Brazilian coffee extract 15 parts

[0115] Tobacco extract 27 parts

[0116] Maple extract 4 parts

[0117] L-menthone 3 parts

[0118] Fenugreek Extract 16 parts

[0119] Licorice Maillard Reaction 8 parts

[0120] 34 parts of solvent

[0121] Wherein, the tobacco extract includes any one or several mixtures of Yunyan extract, Brazilian tobacco extract, and Zimbabwean tobacco leaf extract; the licorice Maillard reactant is a product independently prepared by the company, and the solvent is pure The mixture of water and propylene glycol, and other fragrance raw materials are commercially available products.

[0122] Described table fragrance essence comprises following component by weight part:

[0123...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com