Wet flue gas desulfurization system and wet flue gas desulfurization method

A wet flue gas desulfurization and flue gas technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of difficult removal and high investment costs, and achieve the effect of reducing desulfurization efficiency and increasing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

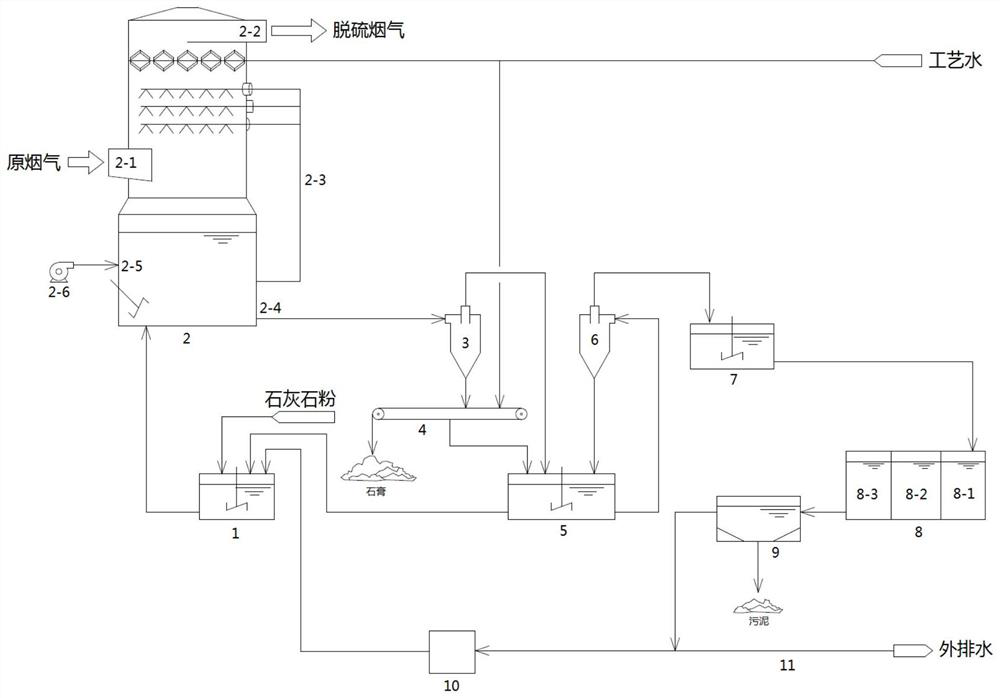

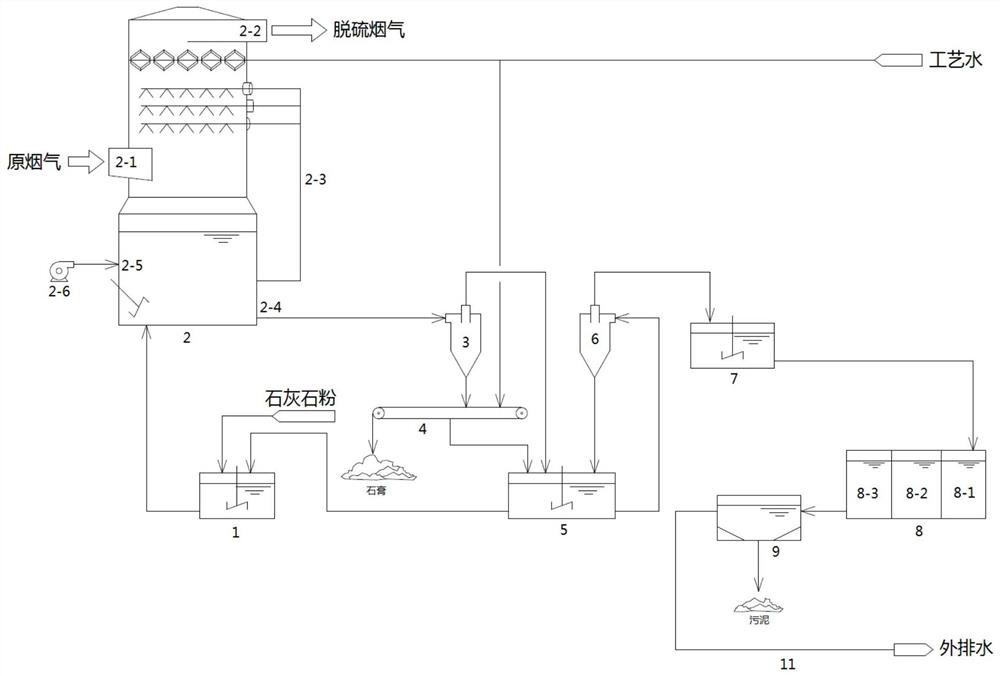

[0084] (1) a kind of as provided in this embodiment figure 1 The wet flue gas desulfurization system shown includes: limestone pulping tank 1, limestone-gypsum method flue gas desulfurization tower 2, gypsum slurry separation equipment 3, gypsum dehydration equipment 4, recovery pool 5, waste water separation equipment 6, waste water collection Pool 7, waste water treatment triple box 8, sedimentation tank 9, advanced oxidation reactor 10, and external drainage pipe 11; wherein, the side wall of the limestone-gypsum flue gas desulfurization tower 2 is provided with an original flue gas inlet 2-1 , the top of the tower is provided with a net flue gas outlet 2-2, the bottom of the tower is provided with a circulating slurry outlet, a gypsum slurry outlet 2-4 and an air inlet 2-5, and the circulating slurry outlet is connected to the slurry circulation pipeline 2-3 of the desulfurization tower The liquid inlet end is connected, the liquid outlet end of the slurry circulation pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com