Method for preparing light olefin by microwave-driven catalytic cracking of crude oil

A light olefin and catalytic cracking technology, which is used in hydrocarbon cracking to produce hydrocarbons, chemical instruments and methods, catalysts, etc., to achieve the effects of increasing utilization value, improving energy efficiency, and reducing high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

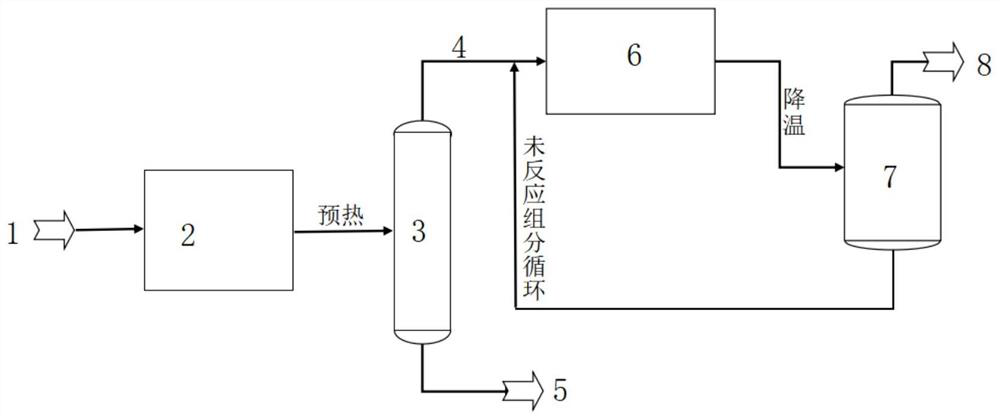

Method used

Image

Examples

Embodiment 1

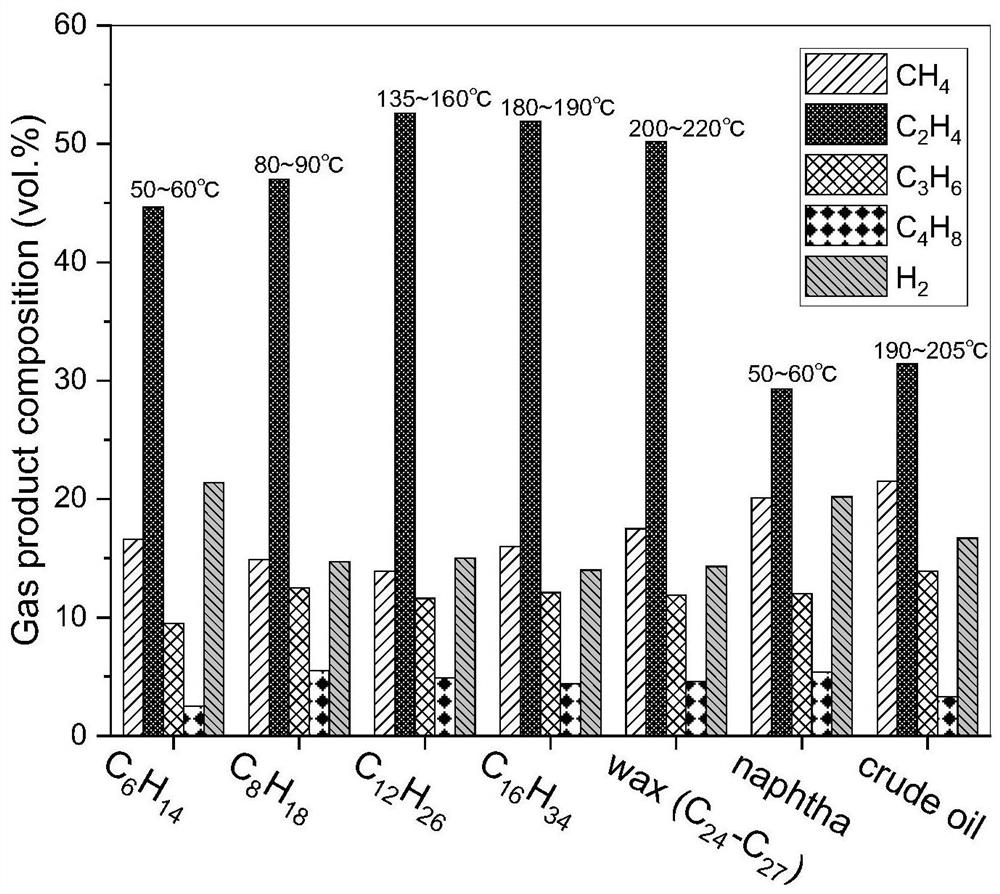

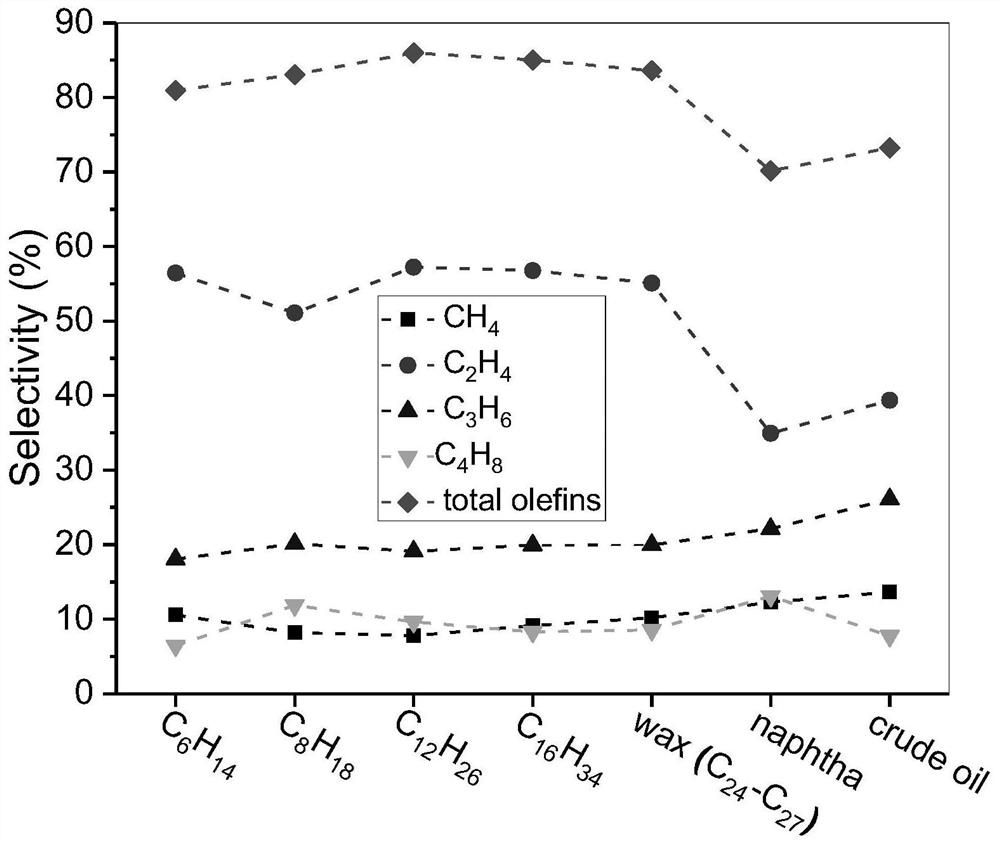

[0039] Considering the complexity of crude oil, the crude oil is firstly divided into representative components such as naphtha fraction (naphtha) and C6-C27 paraffins, and the catalytic cracking evaluation driven by microwave is carried out one by one. The previous crude oil was used as raw material to simulate real crude oil catalytic cracking to produce light olefins.

[0040] In this embodiment, the pressure of the raw material is controlled at 100kPa before entering the flash unit, and the preheating temperature is 250°C.

[0041] The crude oil flashing unit is equipped with a plate-type flashing tower with a theoretical plate number of 5, isothermal flashing operation, the operating pressure is controlled at 10kPa, and the operating temperature is 270°C;

[0042] The equipment of the microwave catalytic cracking reaction unit is a vertical fixed-bed reactor, the microwave frequency is 900MHz, and the microwave irradiation intensity is 1000kW / m 3 , the catalyst is a 120 ...

Embodiment 2

[0047] The representative components in crude oil (naphtha, the final boiling point of naphtha is 205°C) are used as the feed to the microwave catalytic cracking reaction unit to simulate the catalytic cracking of light mixed components in crude oil to produce light olefins.

[0048] In this embodiment, the pressure of the raw material is controlled at 70kPa before entering the flash unit, and the preheating temperature is 200°C.

[0049] The crude oil flashing unit is equipped with a plate-type flashing tower with a theoretical plate number of 3, isothermal flashing operation, the operating pressure is controlled at 50kPa, and the operating temperature is 220°C;

[0050] The equipment of the microwave catalytic cracking reaction unit is a vertical fluidized bed reactor, the microwave frequency is 2.45GHz, and the microwave irradiation intensity is 1500kW / m 3 , the catalyst is 120 mesh SiC powder loaded with 2wt.% carbon; the light fraction vapor enters from the bottom of the ...

Embodiment 3

[0055] All fractions of Saudi light crude oil whose atmospheric boiling point is before 440°C are used as the feedstock of the microwave catalytic cracking reaction unit to simulate the process of producing light olefins from catalytic cracking of real full mixed distillate crude oil.

[0056] In this embodiment, the pressure of the raw material is controlled at 130kPa before entering the flash unit, and the preheating temperature is 300°C.

[0057] The crude oil flashing unit is equipped with a plate-type flashing tower with a theoretical plate number of 5, isothermal flashing operation, the operating pressure is controlled at 3kPa, and the operating temperature is 300°C;

[0058] The equipment of the microwave catalytic cracking reaction unit is a vertical fluidized bed reactor, the microwave frequency is 2.45GHz, and the microwave irradiation intensity is 3000kW / m 3 , the catalyst is 300 mesh MnOx powder loaded with 0.5wt.% of carbon; the light fraction vapor enters from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com