Low-nitrogen, efficient and energy-saving high-temperature and high-pressure circulating fluidized bed boiler

A circulating fluidized bed, high-efficiency and energy-saving technology, used in fluidized bed combustion equipment, steam boilers, and molten fuels, etc., can solve problems such as low boiler efficiency, improve thermal efficiency, prevent local wear, and ensure long-term stability. The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to deepen the understanding of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the scope of protection.

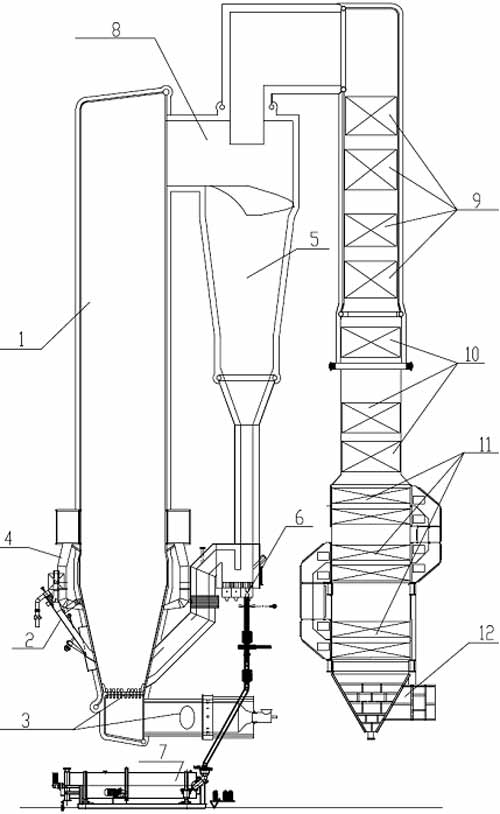

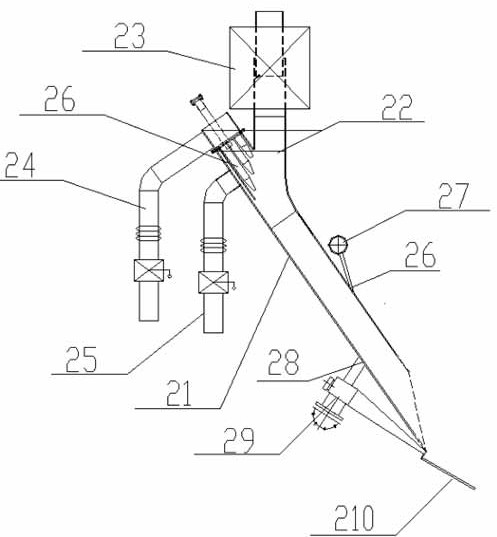

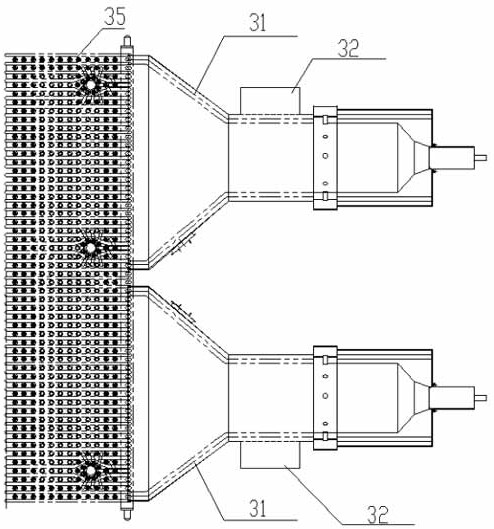

[0065] This embodiment provides a low-nitrogen, high-efficiency and energy-saving high-temperature and high-pressure circulating fluidized bed boiler, which optimizes various systems on the original basis (the existing document is CN106838892A), including the boiler main body and steel frame. Economizer system with adjustable exhaust gas temperature, coal feeding system with anti-blocking and anti-reversal, high-efficiency ratio primary and secondary air system, high-efficiency material separation system, anti-blocking air preheater system, ammonia injection and denitrification in the furnace Systems and Operating Systems; References figure 1 , including the furnace 1 as a whole, the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com