Flexible supercapacitor

A supercapacitor, flexible technology, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve problems such as poor durability, achieve good bending performance, improve foldable performance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

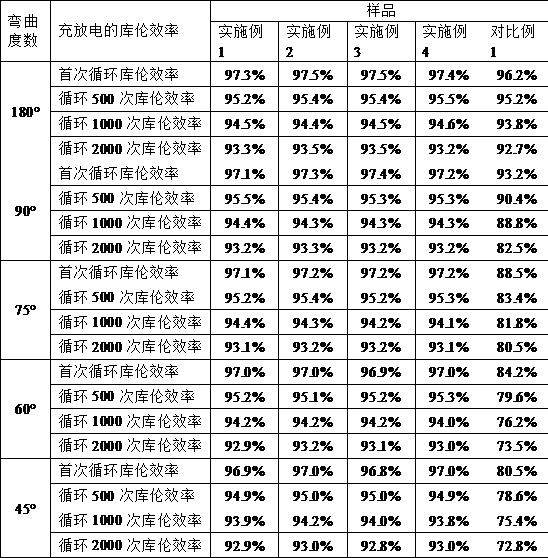

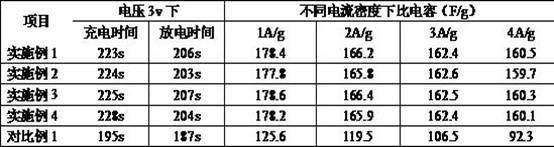

Examples

Embodiment 1

[0029] A preparation method for a flexible supercapacitor, comprising the following steps:

[0030] (1) First, add 25g of tributyl phosphate into the reaction flask, stir and heat to 140°C and keep the temperature, add 8g of N-methylimidazole dropwise into the tributyl phosphate, keep stirring at the temperature for 2 hours to obtain the ionic liquid, and then Dissolve 10 g of microcrystalline cellulose in the ionic liquid, and continue to keep stirring at the temperature for 4 hours to obtain ionic liquid-modified microcrystalline cellulose, which is set aside;

[0031] (2) Take 10 g of the ionic liquid modified microcrystalline cellulose prepared in step (1) in a reaction flask, add 20 g of aluminum chloride in batches under constant stirring in a nitrogen atmosphere, mix well, cool with an ice-water bath, and use CHI760D electrochemical workstation conducts constant current electrolysis and electrodeposition of aluminum. During electrolysis, use magnetic stirring and mainta...

Embodiment 2

[0036] A preparation method for a flexible supercapacitor, comprising the following steps:

[0037] (1) First, add 26g of tributyl phosphate into the reaction flask, stir and heat to 145°C and keep the temperature, add 9g of N-methylimidazole dropwise into the tributyl phosphate, keep stirring for 3 hours to obtain the ionic liquid, and then Dissolve 12 g of microcrystalline cellulose in the ionic liquid, and continue to maintain the temperature and stir for 5 hours to obtain ionic liquid-modified microcrystalline cellulose, which is set aside;

[0038] (2) Take 10 g of the ionic liquid modified microcrystalline cellulose prepared in step (1) in a reaction flask, add 20 g of aluminum chloride in batches under constant stirring in a nitrogen atmosphere, mix well, cool with an ice-water bath, and use CHI760D electrochemical workstation conducts constant current electrolysis and electrodeposition of aluminum. During electrolysis, stir with magnetic force and maintain a constant s...

Embodiment 3

[0043] A preparation method for a flexible supercapacitor, comprising the following steps:

[0044] (1) First, add 27g of tributyl phosphate into the reaction flask, stir and heat to 148°C and keep the temperature, add 9.5g of N-methylimidazole dropwise into the tributyl phosphate, keep stirring for 3.5h at the temperature to obtain the ionic liquid , and then dissolving 13 g of microcrystalline cellulose in the ionic liquid, and continuing to maintain the temperature and stirring for 4.5 hours to obtain ionic liquid-modified microcrystalline cellulose, which is set aside;

[0045] (2) Take 10 g of the ionic liquid modified microcrystalline cellulose prepared in step (1) in a reaction flask, add 20 g of aluminum chloride in batches under constant stirring in a nitrogen atmosphere, mix well, cool with an ice-water bath, and use CHI760D electrochemical workstation conducts constant current electrolysis and electrodeposition of aluminum. During electrolysis, magnetic stirring is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com