Spicy biscuit and making process thereof

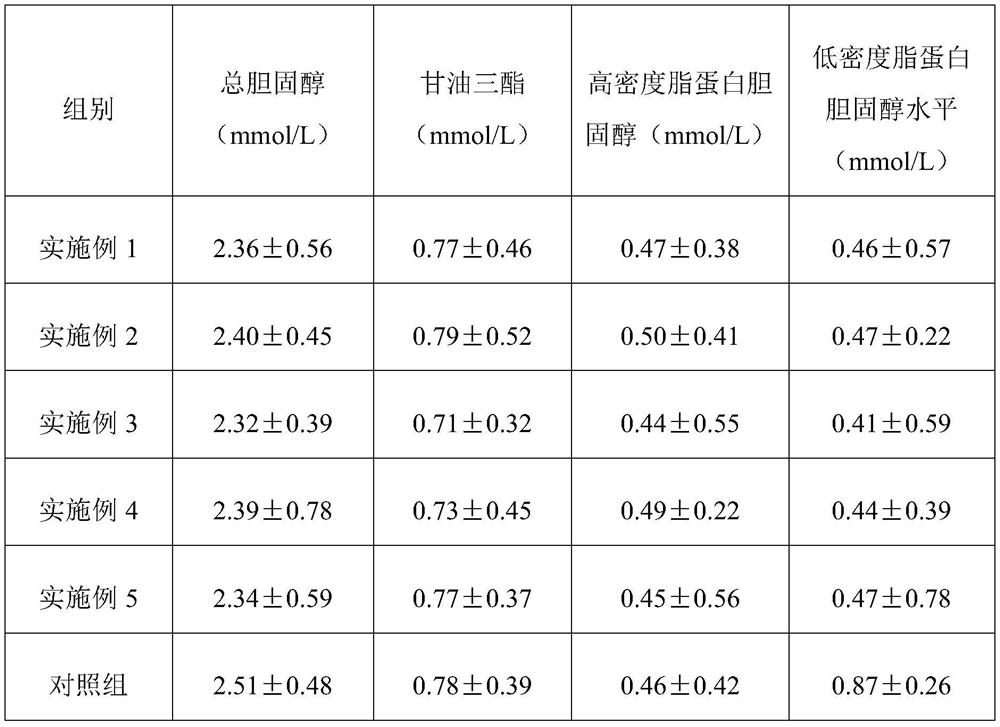

A technology for making biscuits, which is applied in the field of spicy biscuits and their production technology, can solve the problems of no spicy taste, single taste of biscuits, high sugar content, etc., and achieve the reduction of total cholesterol level and simple production process Convenience, effect of increasing appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]A spicy biscuit, comprising the following raw materials in parts by weight: 130g flour, 1.3g pepper, 1.2g mustard, 40g ground shoot melon, 25g palm oil, 2.0g fruit pulp, 9g eggs, 0.4g yeast, 1.2g sugar, Salt 1.5g, raw pepper 0.4g, clove 0.7g, cinnamon 0.7g, Chinese prickly ash 1.2g, white vinegar 0.2g, sweet wine mash 0.9g, cellulase 0.06g, hemicellulase 0.03g and pectinase 0.06g.

[0036] The manufacturing process includes the following steps:

[0037] Raw material pretreatment: remove the shell and seeds of fresh and mature ground shoot melon, put it into a 90-mesh beater, add 120g of water for beating, then take it out and pour it into a container, add cellulase, semi-fiber Stir the prime enzyme and pectinase, then heat to 38°C, keep for 35min, take it out and filter, then centrifuge through the centrifuge to get the clarified ground shoot melon juice, set aside; add chili, mustard, clove, cinnamon and Chinese prickly ash Mesh sieve is pulverized for 130 purpose pulv...

Embodiment 2

[0043] A spicy biscuit, comprising the following raw materials in parts by weight: 150g flour, 1.6g capsicum, 1.6g mustard, 43g ground shoot melon, 28g palm oil, 2.3g fruit pulp, 12g eggs, 0.5g yeast, 1.4g sugar, Salt 1.8g, raw pepper 0.6g, clove 0.8g, cinnamon 0.8g, Chinese prickly ash 1.4g, white vinegar 0.3g, rum 1.1g, cellulase 0.08g, hemicellulase 0.04g and pectinase 0.07g.

[0044] The manufacturing process includes the following steps:

[0045] Raw material pretreatment: Take the fresh and mature ground shoot melon, remove the shell and seeds, put it into a 95-mesh beater, add 129g of water for beating, then take it out and pour it into a container, add cellulase and hemicellulose Stir the suzyme and pectinase, then heat to 37°C, keep for 38min, take it out and filter, then centrifuge through the centrifuge to get the clarified melon juice, set aside; add chili, mustard, clove, cinnamon and pepper Mesh sieve is pulverized for 135 purpose pulverizers, stand-by;

[0046...

Embodiment 3

[0051] A spicy biscuit, comprising the following raw materials in parts by weight: flour 120g, pepper 1.0g, mustard 0.8g, ground shoot melon 37g, palm oil 24g, fruit pulp 1.7g, eggs 6g, yeast 0.3g, sugar 0.9g, Salt 1.3g, raw pepper 0.4g, clove 0.5g, cinnamon 0.5g, Chinese prickly ash 0.9g, white vinegar 0.1g, sweet wine mash 0.7g, cellulase 0.05g, hemicellulase 0.02g and pectinase 0.05g.

[0052] The manufacturing process includes the following steps:

[0053] Raw material pretreatment: remove the shell and seeds from the fresh and mature ground shoot melon, put it into a beating machine with a mesh screen of 85 mesh, and add 74g of water for beating, then take it out and pour it into a container, add cellulase, semi-fiber Stir with primese and pectinase, then heat to 36°C, keep for 39 minutes, take out and filter, and then centrifuge through a centrifuge to obtain clarified ground shoot melon juice for later use; add chili, mustard, cloves, cinnamon and Zanthoxylum bungeanum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com