Method for preparing amino silane functionalized graphene through electrochemical stripping

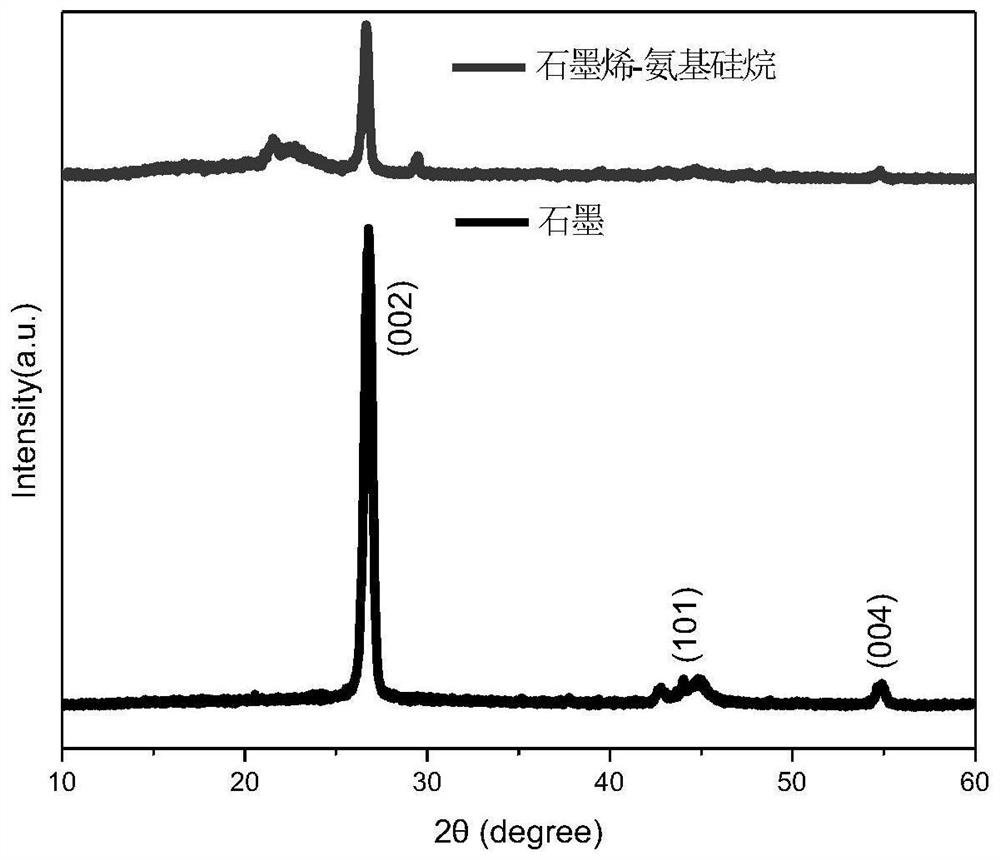

An aminosilane and electrochemical technology, applied in the field of electrochemical exfoliation to prepare aminosilane-functionalized graphene, can solve the problems of less defects, complicated preparation process, good dispersibility, etc. The effect of good performance and complete crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Mix 3-aminopropyltriethoxysilane with deionized water, the volume ratio of 3-aminopropyltriethoxysilane to deionized water is 1:4, and hydrolyze for 5h at room temperature to obtain Aminosilane mixed solution, the aminosilane mixed solution is added to the ammonium sulfate solution (0.1mol / L), the volume ratio of the aminosilane mixed solution and the ammonium sulfate solution is 1:20, and the electrochemical stripping solution is obtained;

[0035] (2) Place the electrolytic cell in an 80°C constant temperature water bath, connect the graphite rod to the anode of the power supply, connect the lead plate to the cathode of the power supply, and immerse the connected graphite rod and lead plate vertically and parallelly into the electrochemical process of step (1). In the stripping solution, under the constant voltage condition of 10V, carry out electrochemical stripping, until no graphite solid is detached from the electrode, the stripping ends, and the graphene precu...

Embodiment 2

[0041] (1) Mix 3-aminopropyltrimethoxysilane with deionized water, the volume ratio of 3-aminopropyltrimethoxysilane to deionized water is 1:4, and hydrolyze for 3 hours at room temperature to obtain aminosilane Mixed solution, adding the aminosilane mixed solution to the ammonium sulfate solution (0.5mol / L), the volume ratio of the aminosilane mixed solution and the ammonium sulfate solution is 1:100, to obtain an electrochemical stripping solution;

[0042] (2) Place the electrolytic cell in a 70°C constant temperature water bath, connect the graphite rod to the anode of the power supply, connect the lead plate to the cathode of the power supply, and immerse the connected graphite rod and lead plate vertically and parallelly into the electrochemical process of step (1). In the peeling solution, under the condition of 5V constant voltage, electrochemical peeling is carried out until no graphite solid is separated from the electrode, and the peeling is completed, and the graphe...

Embodiment 3

[0045] (1) Mix 3-aminopropyl monomethyldiethoxysilane with deionized water, the volume ratio of 3-aminopropyl monomethyldiethoxysilane to deionized water is 1:4, at room temperature Under the conditions of hydrolysis for 8h, the aminosilane mixture was obtained, and the aminosilane mixture was added to the ammonium sulfate solution (0.3mol / L), and the volume ratio of the aminosilane mixture to the ammonium sulfate solution was 1:50, and the electrochemical stripping solution;

[0046] (2) Place the electrolytic cell in a 90°C constant temperature water bath, connect the graphite rod to the anode of the power supply, connect the lead plate to the cathode of the power supply, and immerse the connected graphite rod and lead plate vertically and parallelly into the electrochemical process of step (1). In the stripping solution, under the constant voltage condition of 15V, electrochemical stripping is carried out until no graphite solid is detached from the electrode, and the strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com