Novel biodegradable plastic material and preparation method thereof

A technology for degrading plastics and new materials, applied in the field of new materials for biodegradable plastics and its preparation, can solve the problems of low strength of degradable plastics, achieve the effects of easy degradation, guarantee its own strength, and solve low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The novel material of biodegradable plastics of the present application comprises resin, lignocellulose, nano-zeolite and cellulase; Described resin is polyethylene; The weight content of resin, lignocellulose, nano-zeolite and cellulase is respectively in the material : 65-78% resin, 22-27% lignocellulose, 5-10% nano-zeolite, 0.2-0.4% cellulase; the preparation method is as follows:

[0085] (1) immobilize cellulase on nano zeolite by physical adsorption at room temperature;

[0086] (2) Using mixing equipment, first mix the nano-zeolite solidified with cellulase and lignocellulose in proportion;

[0087] (3) mixing the mixture obtained in step (2) with the resin in proportion;

[0088] (4) Transport the mixture obtained in step (3) to a granulator for granulation.

[0089] Preferably, the cellulase is heat-resistant cellulase derived from B. subtilis DR bacteria.

[0090] The fineness of the nano-zeolite is 0.08mm, and the average particle diameter is 5.0-6.5 μm. ...

Embodiment 2

[0096] In order to further shorten the degradation time of the material (considering that raising the ambient temperature is conducive to improving the activity of cellulase and thus shortening the degradation time of the material of this application), preferably, the material of this application also includes reduced iron powder, carbon powder and Salt; the weight content of reduced iron powder, carbon powder and table salt in the material is: reduced iron powder 1.6-3%, carbon powder 1.5-2%, salt 0.5-0.8%; the step (3) is: the reduced iron powder , carbon powder and table salt are mixed in proportion; the mixture obtained by mixing reduced iron powder, carbon powder and table salt is mixed with the mixture obtained in step (2) and resin in proportion.

[0097] After utilizing the material of this embodiment to make plastic products, the reduced iron powder, carbon powder and salt react with air or water in the soil to release heat, which increases the surface temperature of t...

Embodiment 3

[0102] Considering that the content of some raw materials in the above-mentioned embodiments of the present application is relatively small, using the mixing equipment in the prior art to mix the raw materials in the above-mentioned embodiments is prone to the problems of uneven mixing and low mixing efficiency;

[0103] This embodiment provides a mixing device, which is used in the material preparation (process) process of this application, which solves the problem of mixing a small amount of one or more raw materials with a larger amount of one or more raw materials in the prior art. The technical problems of uneven mixing and low mixing efficiency that are likely to occur when mixing multiple raw materials are as follows:

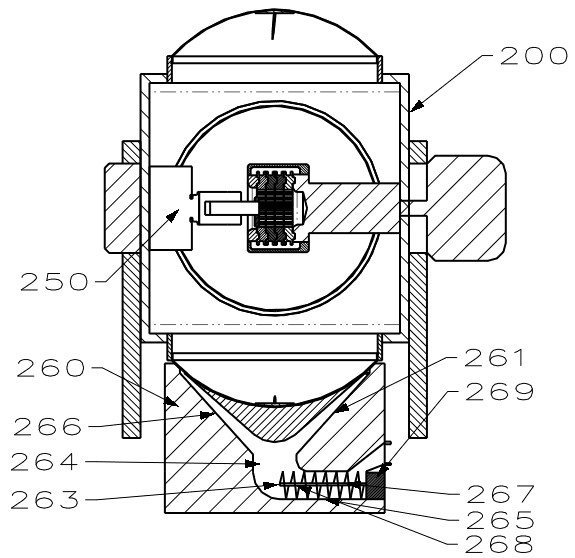

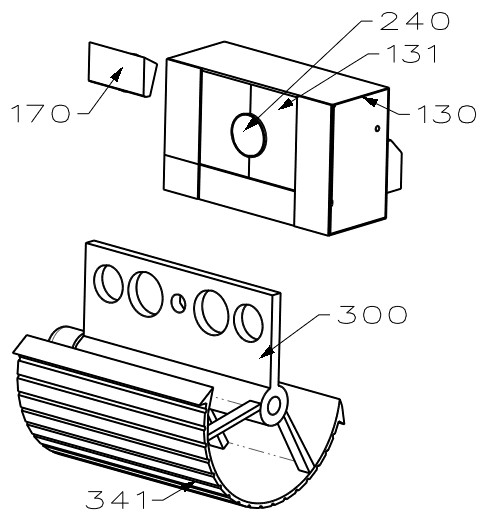

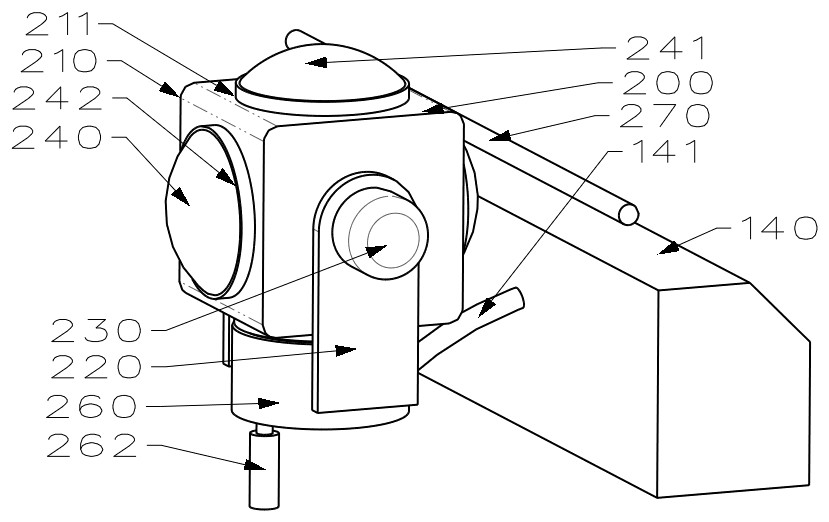

[0104] like Figure 1 to Figure 5 As shown, the mixing device of the present application includes a housing 100, a cloth assembly 200, a stirring and mixing assembly 300, an ion fan 400, a power assembly and a control unit.

[0105] like Figure 5 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com