Method for extracting hermetia illucens prepupa grease

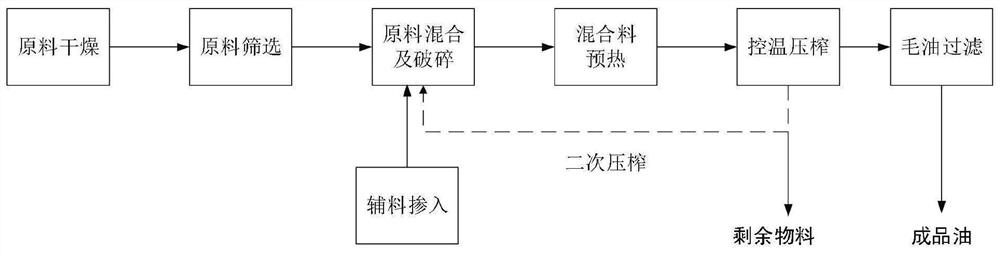

An extraction method and technology for Heishui horsefly, which are applied in the directions of fat oil/fat production, fat oil/fat refining, and fat production, etc., can solve the problems of complicated operation, environmental pollution, and many process steps, and achieve the effect of ensuring the use value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the present invention, the preparation method of described dry black soldier fly prepupa preferably comprises the following steps:

[0028] Drying and screening the black soldier fly prepupa raw materials in sequence to obtain dry black soldier fly prepupa.

[0029] In the present invention, the present invention has no special requirements on the source of the black soldier fly prepupae, and the black soldier fly prepupae from sources well known in the art can be used, such as self-cultivated or commercially available.

[0030] In the present invention, the drying method preferably includes one or more of electrothermal drying, microwave drying and freeze drying. In the present invention, the temperature of the electrothermal drying is preferably 60-105° C., more preferably 80-90° C., and the time is preferably 4-6 hours, more preferably 5 hours.

[0031] In the present invention, the power of the microwave drying is preferably 500-900W, more preferably 600-800W; t...

Embodiment 1

[0047] The extraction method of black soldier fly prepupa oil comprises the following steps:

[0048] (1) The black soldier fly prepupa is dried by electric heating to a moisture content of 5 wt%, and an oil content of 35%.

[0049] (2) The dried worms obtained in step 1 are separated by wind and magnetic separation system, and the wind speed is set at 5m / s to remove impurities generated during the drying process.

[0050] (3) The dried worms obtained in step 2 are mixed with barley and then enter the crusher to be crushed into fine pieces with a particle size of 2-4 mm.

[0051] (4) The dried worms obtained in step 3 are preheated at a temperature of 50°C.

[0052](5) The raw material obtained in step 4 is hot-pressed by using a screw press at a temperature of 100°C.

[0053] (6) The crude oil obtained in step 5 is subjected to centrifugal primary filtration under 8000 g of centrifugal force, and the obtained supernatant is subjected to secondary filtration with a filter pr...

Embodiment 2

[0055] The extraction method of black soldier fly prepupa oil comprises the following steps:

[0056] (1) The black soldier fly prepupa is freeze-dried to a moisture content of 3% and an oil content of 42%.

[0057] (2) The dried worms obtained in step 1 are separated by wind and magnetic separation system, and the wind speed is set to 6m / s to remove impurities generated during the drying process.

[0058] (3) Add the dried worms obtained in step 2 into corn and mix them into a crusher, and crush them into fine pieces with a particle size of 2 to 4 mm.

[0059] (4) The raw material obtained in step 3 is cold-pressed by a screw press at a temperature of 50° C., and the obtained residue is re-crushed and then cold-pressed again.

[0060] (5) All the crude oil obtained in step 4, and then the centrifugal force is controlled at 10000g for centrifugal primary filtration, and the obtained supernatant is subjected to secondary filtration with a filter press at a pressure of 0.25 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com