Isoparametric transformation mixed structure of bionic bone scaffold and 3D printing method thereof

A 3D printing and hybrid structure technology, applied in 3D object support structures, bone implants, geometric CAD, etc., can solve the problem that the bionic scaffold cannot meet the pore structure, mechanical properties and materials at the same time, so as to prevent the decline of mechanical properties, The effect of high Young's modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

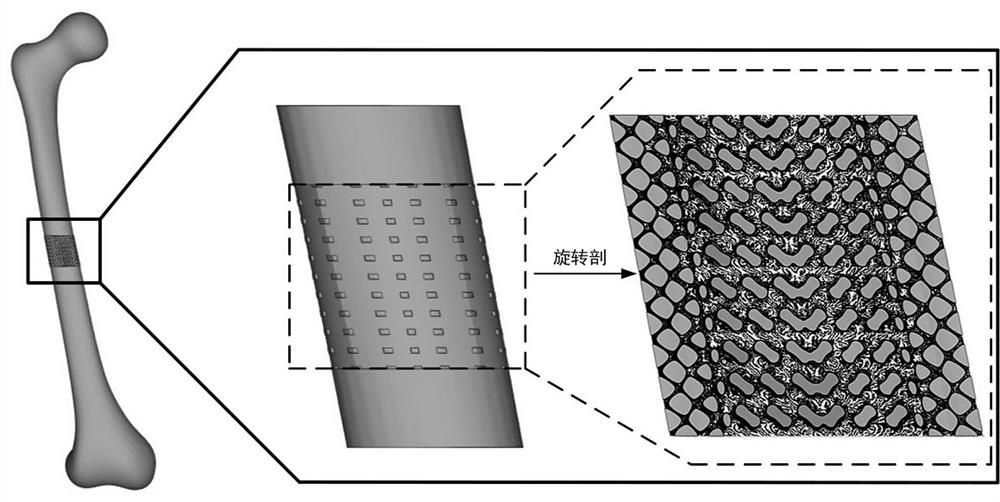

[0081] Such as figure 1 As shown, a bionic bone scaffold designed for this embodiment can well match the shape and mechanical properties of the femoral shaft. The general process of constructing the bionic bone scaffold is as follows:

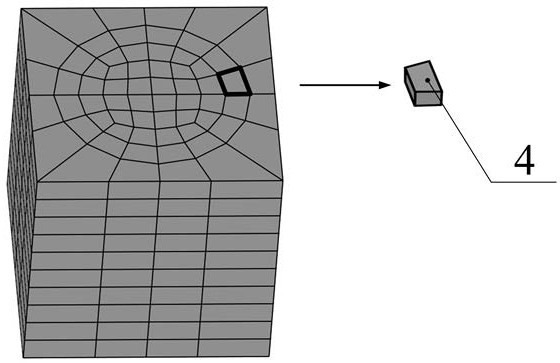

[0082] First, generate a cube model with a side length of 25mm. Then, pass the cube model through figure 2 and image 3 The partitioning method shown is partitioned into a series of subspaces 4 . Next, the minimal curved surface structure cell 5 whose space is a regular cube is carried out according to the space node parameters of the subspace 4 as follows Figure 5 As shown in the linear isoparametric transformation, the transformed minimum surface structure cell 7 is obtained, and the transformed minimum surface structure cell 7 is filled in all the divided subspaces 4, and the following is obtained: Figure 6 The biomimetic bone scaffold shown. Finally, through the secondary isoparametric transformation, the shape of the bionic bone ...

Embodiment 2

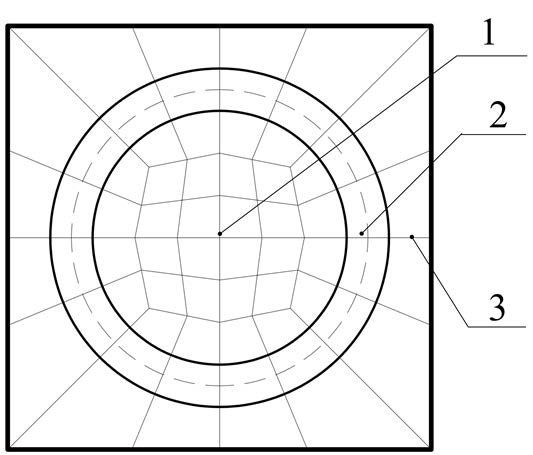

[0120] Further, as figure 2 As shown, the bionic bone scaffold is divided into three layers from inside to outside, which are inner layer 1, transition layer 2 and outer layer 3 respectively. The inner layer 1 has a diameter of 15mm and a porosity of 70%, simulating cancellous bone; the transition layer 2 has an inner diameter of 15mm and an outer diameter of 20mm, and the porosity decreases linearly from 70% to 10%; the outer layer 3 has an inner diameter of 20mm, and the outer The side length is 25mm, and the porosity is 10%, simulating dense bone. Such as Figure 15 The inner layer 1 structure adopts the Network-type Diamond structure 10, the outer layer 3 adopts the Network-type Primitive-Opt structure 11, the inner layer adopts the transition layer 2 and uses the Sigmond function to fuse the two structures of the inner layer 1 and the outer layer 3, and the fusion boundary line is figure 2 The dotted circle in the dotted line has a radius of 8.75mm.

[0121] The form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com