Method for extracting agilawood liquid

An extraction method and technology of agarwood liquid, applied in separation methods, chemical instruments and methods, solvent extraction and other directions, can solve problems such as inability to realize agarwood essential oil, and achieve the effects of increasing extraction rate, improving solubility, and improving dissolution range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

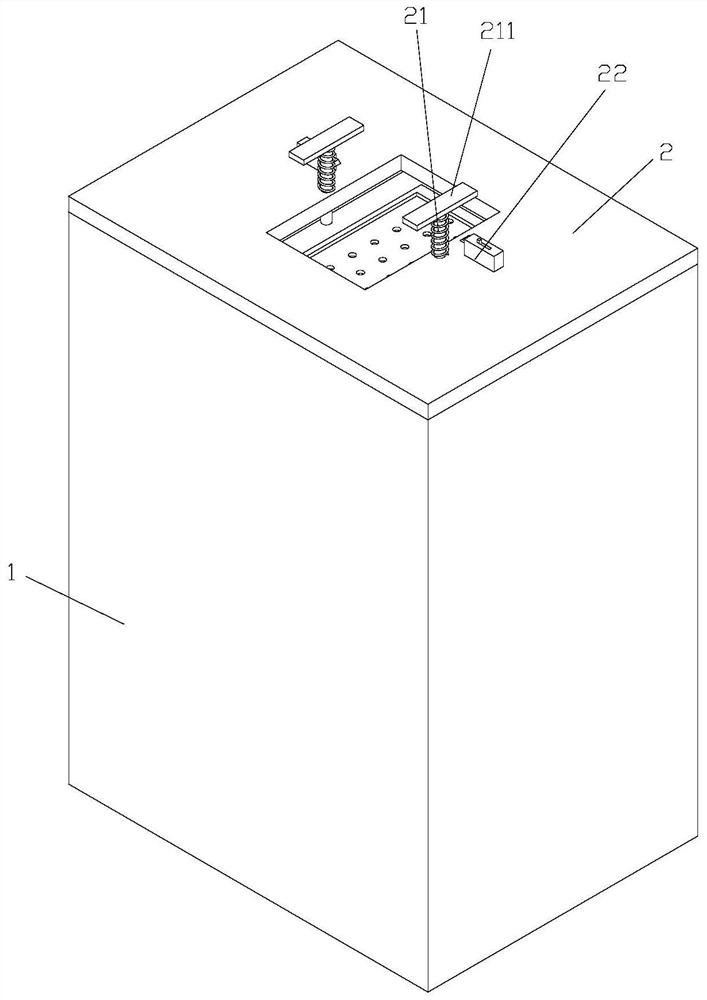

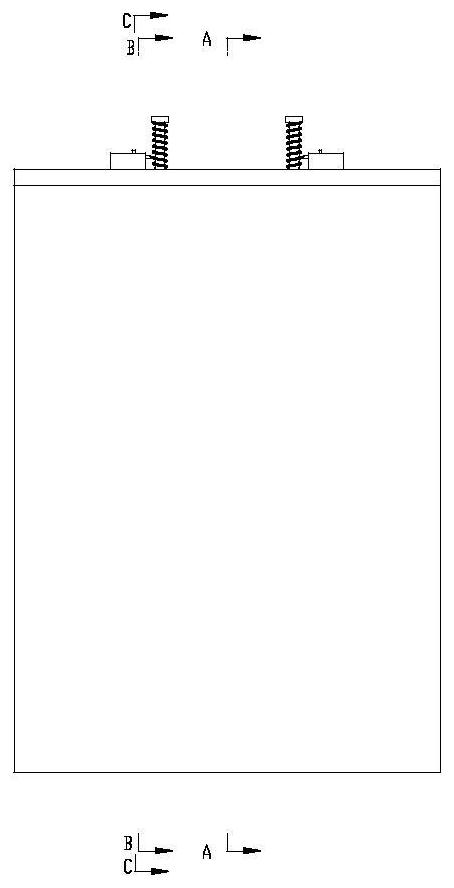

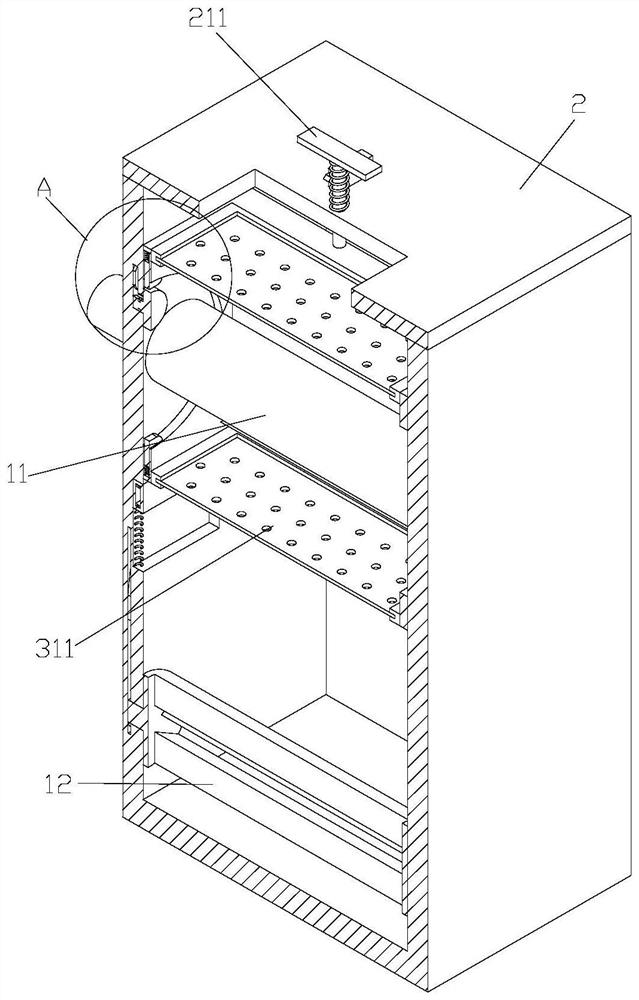

Image

Examples

Embodiment Construction

[0049] One kind of incense liquid extraction method, comprising the steps of: a, the incense ingredients put into the pulverized into an average particle diameter of 50 Chinese medicine grinder object of incense material powder, raw material powder with 5% by weight of ethanol as an entrainer with the raw material powder mixed to obtain a raw material solution; B, step a resulting raw material solution introduced into the extraction vessel, the supercritical carbon dioxide enter into the extraction vessel, the extraction pressure 30MPa, extraction extracted at a temperature of 55 ℃, extraction time for 3.5 h; C, the extract dissolved in the supercritical carbon dioxide fluid through the relief valve into the rectification column separation, rectification column pressure of 22MPa, temperature 60 ℃, distillation time for 4.5 h, the solubility of the wax component is small, oil resin oils and fat deposition at the bottom of the rectification column; D, Shen greater solubility in etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com