Preparation method of polyvinyl alcohol ultrathin selective layer nanofiltration membrane

A polyvinyl alcohol and selective layer technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor mechanical properties, easy swelling, thick thickness, etc., to reduce transmission resistance, enhance mechanical strength, reduce The effect of small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Ⅰ The preparation process of polyvinyl alcohol solution is as follows:

[0033] Weigh 0.2-0.3 g of polyvinyl alcohol (with an alcoholysis degree of 99-99.4 mol%), add it to 200 ml of water, continue stirring for 3-4 h under constant temperature heating at 95-98 °C, and cool to room temperature to obtain 0.1-0.15 wt% The polyvinyl alcohol aqueous solution;

[0034] The preparation process of Ⅱ crosslinking agent hexafluorodianhydride solution is as follows:

[0035] Weigh a certain mass of hexafluorodianhydride (AR, 99%) and add it to 200ml of absolute ethanol, under constant temperature heating at 35 to 40 °C, continue stirring for 1 to 1.5 hours, and cool to room temperature to obtain a certain concentration of hexafluorodianhydride. Anhydride crosslinking agent solution;

[0036] The preparation process of Ⅲ surfactant sodium lauryl sulfate solution is as follows:

[0037] Weigh 0.3-0.4 g of sodium dodecyl sulfate (AR, 98.0%) into 200 ml of deionized water, continu...

example 1

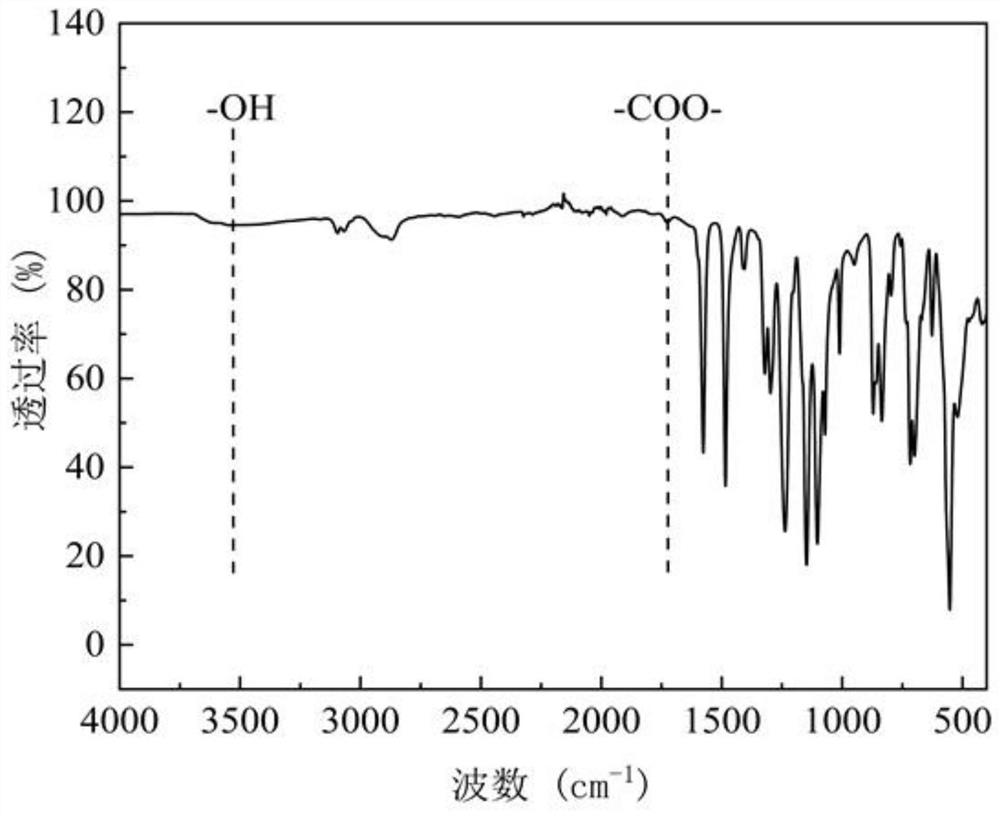

[0043] The infrared spectrum of example 1 is as follows figure 1 As shown, among them, the characteristic peak of ester group (-COO-) appeared near 1730cm-1, indicating that polyvinyl alcohol did undergo esterification reaction with the cross-linking agent, and the cross-linking was successful.

example 2

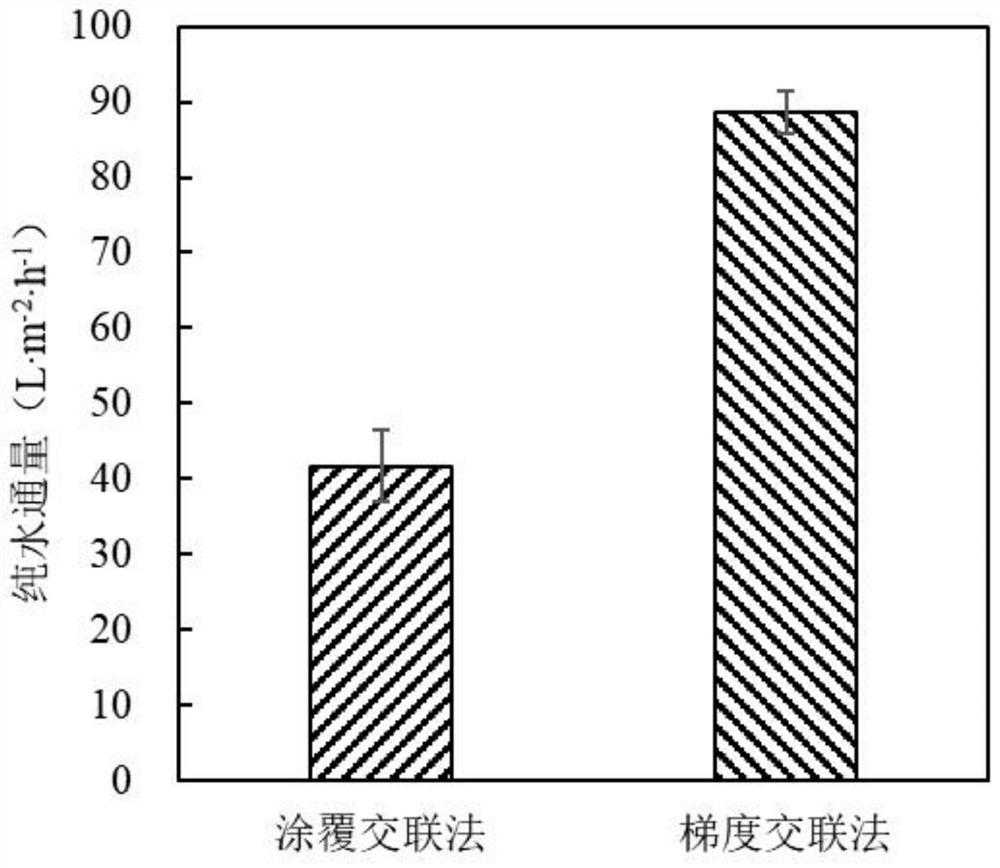

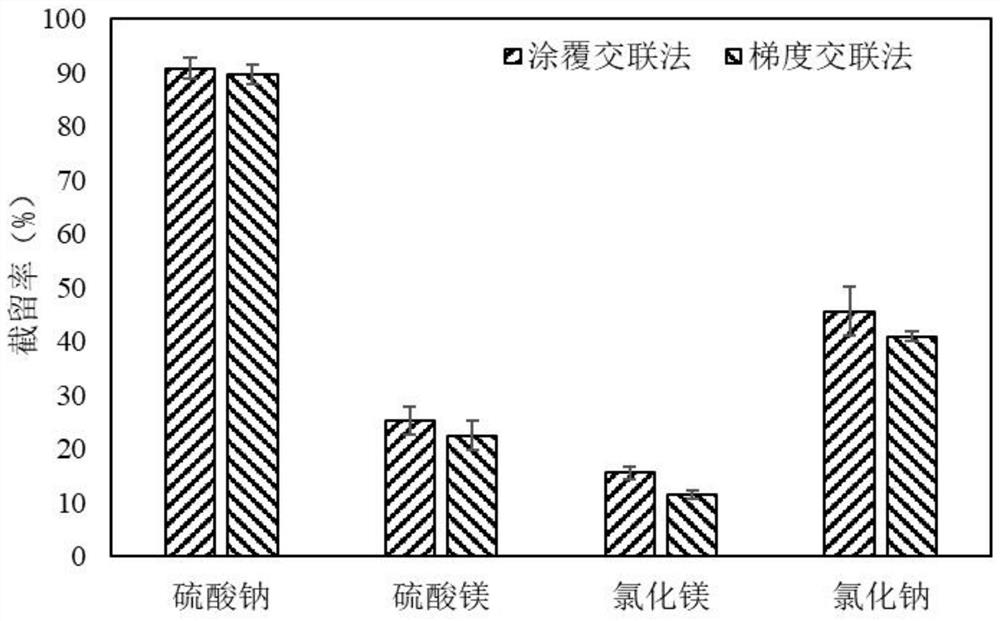

[0044] Example 2 and the nanofiltration membrane prepared by the traditional coating and crosslinking method are as follows: pure water flux, retention effect on salt and morphology figure 2 , 3 , 4 and 5, it can be seen from the figure that the thickness of the selective layer of the polyvinyl alcohol-hexafluorodianhydride nanofiltration membrane prepared by the gradient crosslinking method is much smaller than that of the nanofiltration membrane prepared by the traditional coating and crosslinking method, and its performance better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com