Method for high-efficiency concentration and dechlorination of phosphoric acid

A chlorophosphoric acid, high-efficiency technology, applied in chemical instruments and methods, separation methods, phosphorus compounds, etc., can solve the problems of low production capacity and low concentration efficiency, and achieve the effect of high production capacity and high concentration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

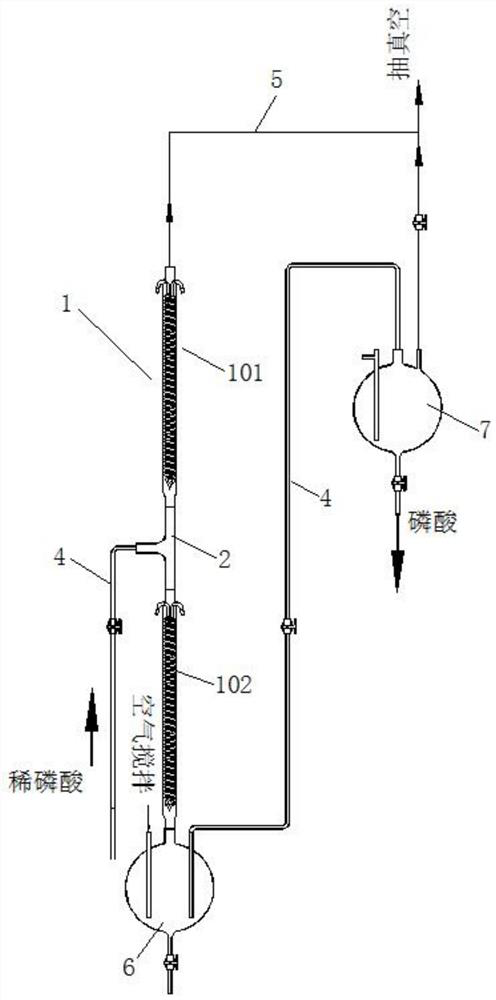

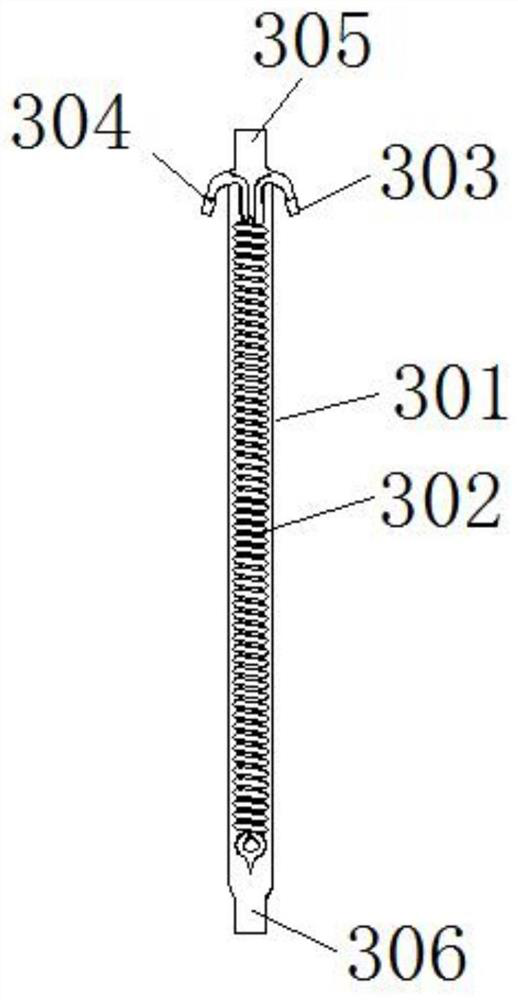

[0027] Such as figure 1 and figure 2 As shown, a high-efficiency concentration system for concentration and removal of chlorinated phosphoric acid, which includes:

[0028] The first-stage thin-film concentration system 1 is used for evaporating and concentrating phosphoric acid. The first-stage thin-film concentration system 1 is formed by connecting two thin-film concentrators 3 in series to form a first-stage thin-film concentrator 101 and a second-stage thin-film concentrator 102. The first-stage thin-film concentrator The material outlet of 101 and the material inlet of the secondary membrane concentrator 102 are connected through the feed joint 2 to realize series connection; the material delivery pipeline 4 is connected to the feed joint 2 to transport phosphoric acid to the primary membrane concentration system 1;

[0029] The vacuum system is used to draw a vacuum to the primary film concentration system 1. The vacuum system includes a vacuum pump (not shown in the ...

Embodiment 2

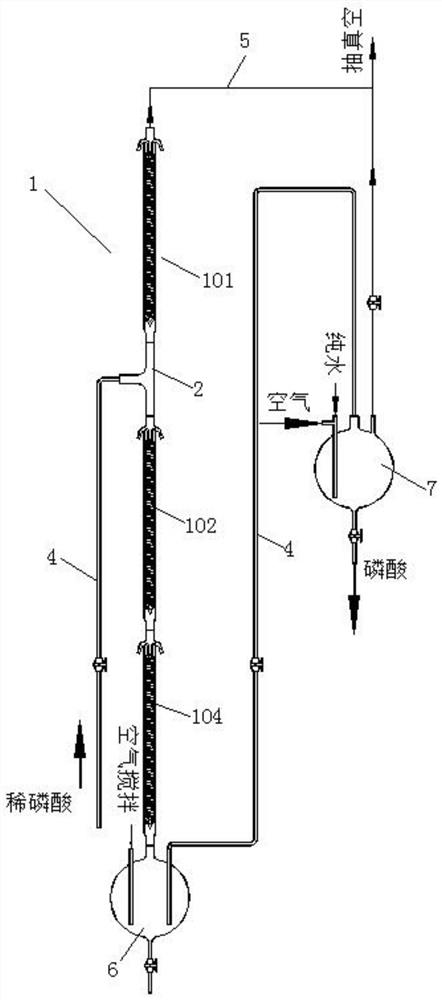

[0037] This embodiment is the same as Embodiment 1, and the difference is that the first-stage thin-film concentration system 1 also includes a third-stage thin-film concentrator 103, such as image 3 As shown, the third-stage thin-film concentrator 103 is directly connected in series with the second-stage thin-film concentrator 102. By performing secondary evaporation and concentration on the material (dilute phosphoric acid), the evaporation concentration efficiency and evaporation concentration effect of the first-stage thin-film concentration system 1 can be improved.

Embodiment 3

[0039] Embodiment 3 is the same as Embodiment 2, and its difference is that, on the material delivery pipeline 4 that described final product reactor 7 is connected with primary reactor 6, there is final product film concentrator 8 connected in series, as Figure 4 As shown, the final product membrane concentrator is used to regulate the temperature of phosphoric acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com