Vibration and noise reduction material and preparation method thereof

A technology for vibration and noise reduction and raw materials, applied in the field of materials, can solve the problems of small vibration frequency range, large proportion of metal vibration and noise reduction materials, and reduced vibration and noise reduction performance, so as to broaden the use frequency range and improve the use temperature. range, the effect of improving vibration and noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

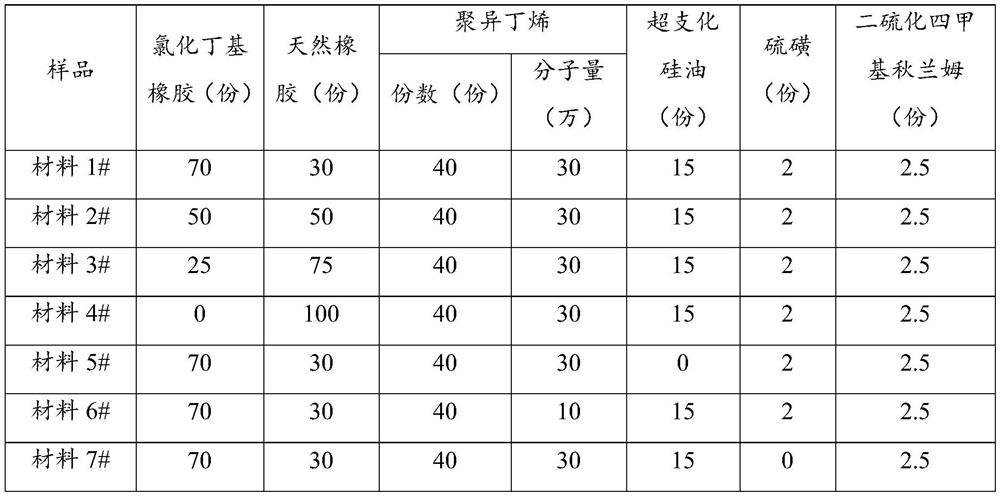

Embodiment 1

[0039] (1) Mixing: Weigh chlorinated butyl rubber, natural rubber, high molecular weight polyisobutylene, hyperbranched silicone oil and various fillers in proportion with an electronic scale or an electronic balance, and use a double-roller rubber mixer to process the chlorinated butyl rubber. , natural rubber, high molecular weight polyisobutylene and hyperbranched silicone oil are mixed and masticated for 8 to 12 times, then plasticizers, weighting agents, reinforcing agents and deodorants are added, and flame retardants are added several times after the ingredients are eaten When the material is completely eaten, after the filler is completely eaten, use a cutter to cut and roll from both sides of the film, and after pouring the glue at least 5 times, the film is unloaded to obtain the initial mixed film, and it is left to air for at least 2 hours;

[0040] (2) Add vulcanizing agent: turn on the cooling water of the double-roller rubber mixing machine, lock the roller dista...

Embodiment 2

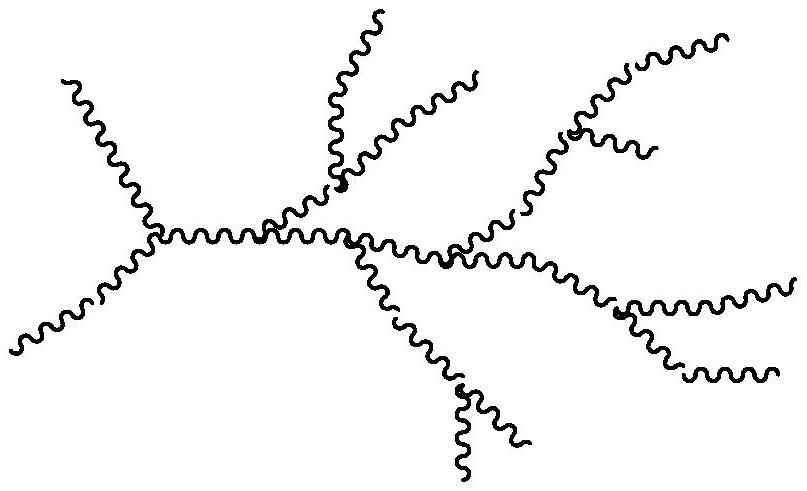

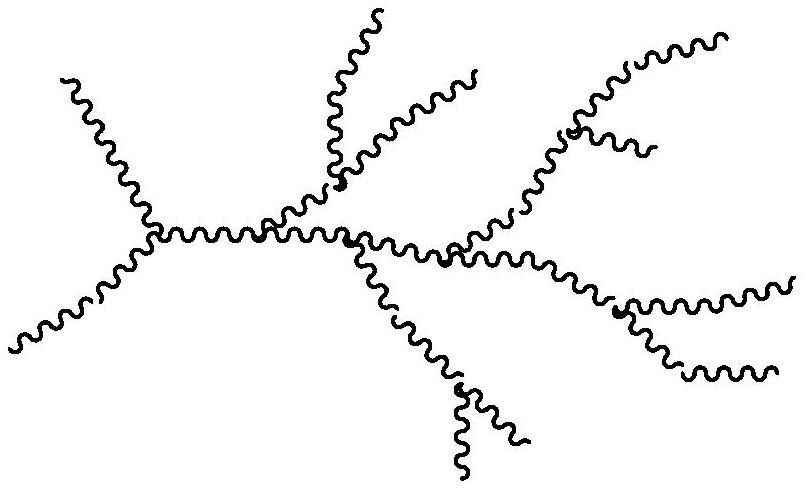

[0054] This embodiment 2 specifically relates to the preparation method of the hyperbranched silicone oil used in embodiment 1, specifically as follows:

[0055] In a reaction kettle equipped with a stirring device, add Si-H content of 0.010%-1.565% (wt%) hydrogen-containing silicone oil, monohydroxyl-terminated silicone oil and tris(pentafluorophenyl)borane, wherein Si-H and The molar ratio of monohydroxy silicone oil is about 1:1.01, the added weight of tris(pentafluorophenyl)borane is 0.1%-2% of the raw material, stir mechanically, react at the reaction temperature of 40°C for 4h, add tris(pentafluorophenyl)borane (Pentafluorophenyl) borane with an appropriate amount of triethylamine, fully stirred, filtered, and removed low boilers under reduced pressure to obtain a colorless hyperbranched silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com