A kind of nano flame-resistant concrete protective coating and preparation method thereof

A technology for protecting coatings and concrete, applied in anti-corrosion coatings, fire-resistant coatings, coatings, etc., to achieve super-long weather resistance, improve adhesion and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

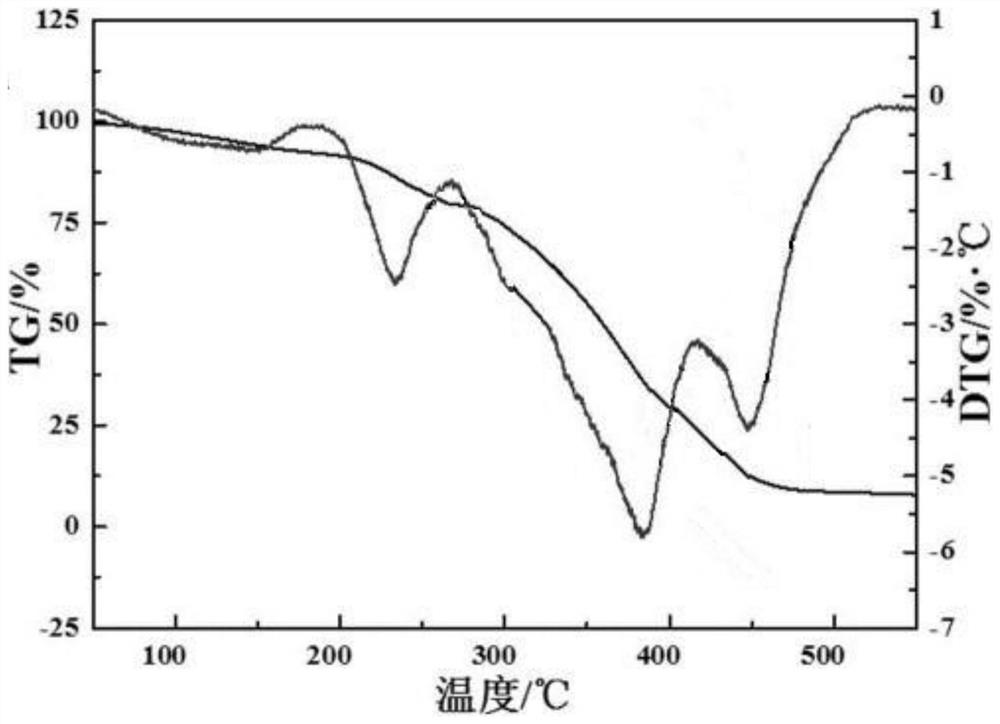

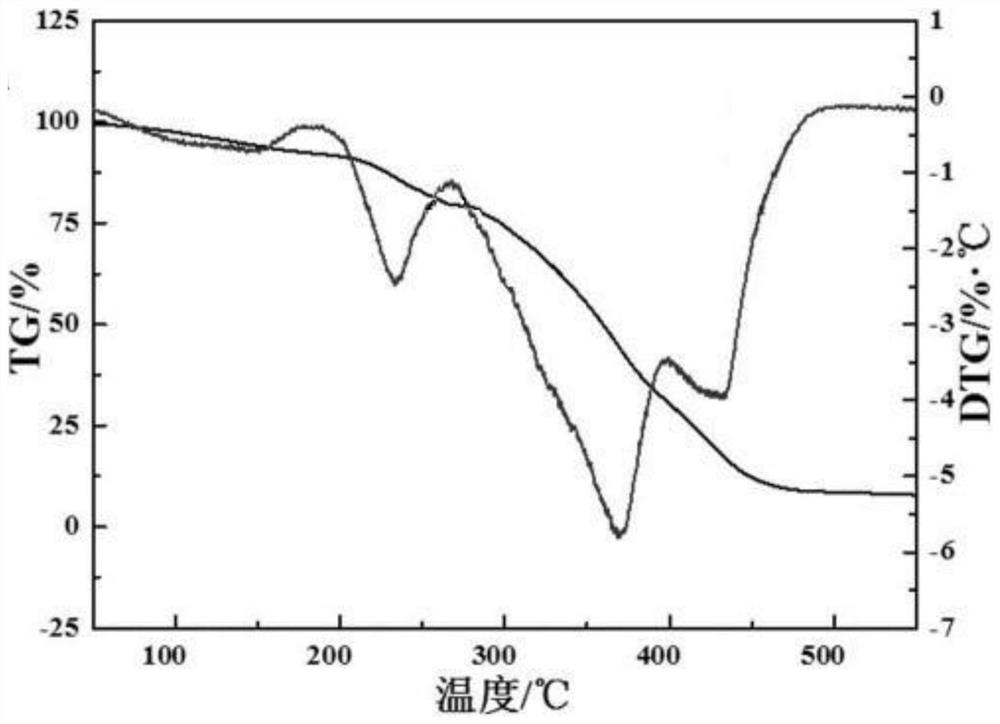

Image

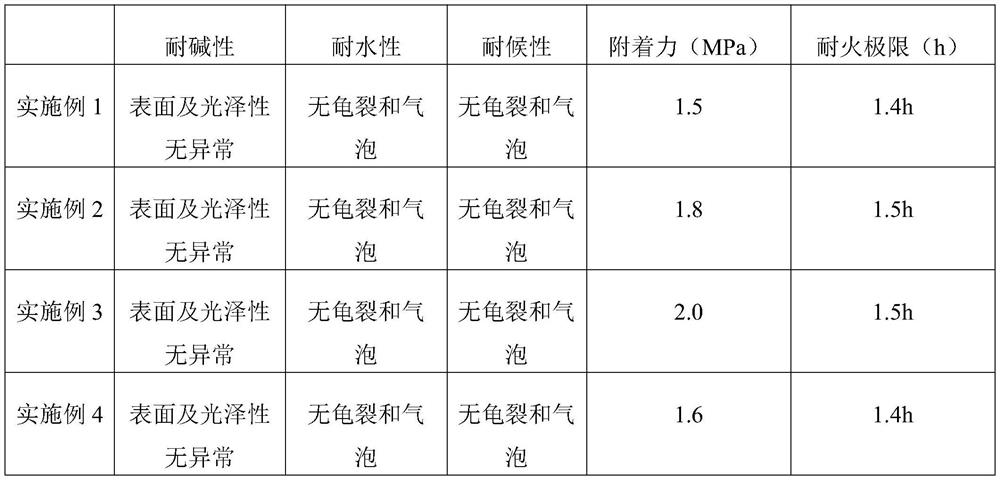

Examples

Embodiment 1

[0031] Provide a kind of nanometer flame-resistant concrete protective coating, including the following components by weight: 55 parts of modified nano-silica sol emulsion, 10 parts of attapulgite whiskers, 5 parts of Schiff base modified graphene composite, wetting and dispersing agent Digao 2450.2 parts, thickener sodium carboxymethyl cellulose 0.2 part, defoamer mineral oil silicon-based mixture 0.5 part, leveling agent BYK37203 parts, deionized water 35 parts.

[0032] The preparation process of the above-mentioned modified nano-silica sol emulsion comprises the following steps:

[0033] Slowly add 3-methacryloyloxypropyltrimethoxysilane modifier, appropriate amount of surfactant and water to the nano-silica sol under stirring, wherein 3-methacryloyloxypropyltrimethoxysilane The amount of silane modifier added is 1.5 wt% of the nano-silica sol. After adding, continue stirring for more than 10 hours until a milky white and translucent low-viscosity emulsion is obtained, whi...

Embodiment 2

[0042] An inorganic weather-resistant concrete protective coating is provided, comprising the following components by weight: 62 parts of modified nano-silica sol emulsion, 9 parts of attapulgite whiskers, 4 parts of Schiff base modified graphene composite, wetting and dispersing agent Digao 2450.3 parts, thickener hydroxyethyl cellulose 0.3 part, defoamer aliphatic hydrocarbon emulsion 0.4 part, leveling agent BYK37202 part, deionized water 32 parts.

[0043] The preparation process of the above-mentioned modified nano-silica sol emulsion comprises the following steps:

[0044] Slowly add 3-methacryloyloxypropyltrimethoxysilane modifier, appropriate amount of surfactant and water to the nano-silica sol under stirring, wherein 3-methacryloyloxypropyltrimethoxysilane The amount of the silane modifier added is 1.6 wt% of the nano-silica sol. After the addition, the stirring is continued for more than 10 hours until a milky white and translucent low-viscosity emulsion is obtained...

Embodiment 3

[0053] An inorganic weather-resistant concrete protective coating is provided, comprising the following components in parts by weight: 68 parts of modified nano-silica sol emulsion, 9 parts of attapulgite whiskers, 4 parts of Schiff base modified graphene composite, wetting and dispersing agent Digao 2450.4 parts, thickener polyvinylpyrrolidone 0.4 part, defoamer polyether organic compound 0.4 part, leveling agent BYK37202 part, deionized water 28 part.

[0054] The preparation process of the above-mentioned modified nano-silica sol emulsion comprises the following steps:

[0055] Slowly add 3-methacryloyloxypropyltrimethoxysilane modifier, appropriate amount of surfactant and water to the nano-silica sol under stirring, wherein 3-methacryloyloxypropyltrimethoxysilane The addition amount of the silane modifier is 1.7 wt% of the nano-silica sol. After the addition, the stirring is continued for more than 10 hours until a milky white and translucent low-viscosity emulsion is obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com