Integrated electrochemical microcolumn platform and application thereof

An electrochemical and integrated technology, applied in the direction of material electrochemical variables, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of low sensitivity of cell monitoring, cost of cell culture, high efficiency and low accuracy, etc. Achieve the effect of improving accuracy and sensitivity, improving sensitivity and accuracy, and good accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

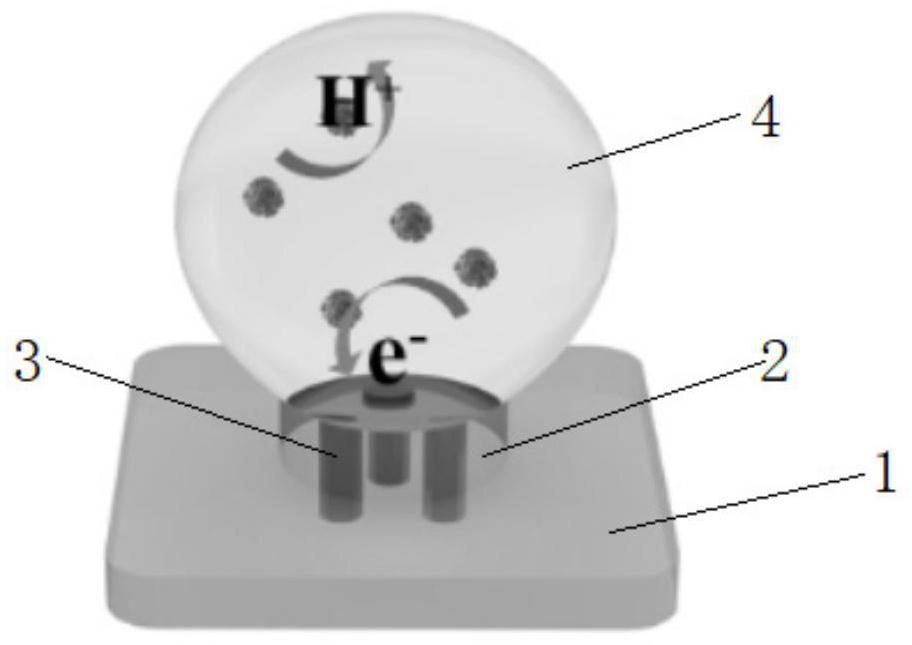

[0059] In the embodiment of the present application, the preparation method of the integrated cloud electrochemical micro-column platform includes the following steps: preparing the cell micro-column culture unit, and culturing the micro-droplet detection unit, that is, the three-electrode system axially through the cell micro-column The micro-column of the unit, so that the detection end of the micro-droplet detection unit is flush with the upper end of the micro-column or slightly higher than the upper end of the micro-column, and is used to contact the micro-droplet loaded by the micro-column to collect electrochemical signals in the micro-droplet, The other end is connected to the integrated cloud electrochemical work unit. Specifically, the electrode wire of the three-electrode system can be guided through the microcolumn of the cell microcolumn culture unit with a needle. After the integrated cloud electrochemical work unit is powered on, it can communicate with the data ...

Embodiment 1

[0074] Example 1: Preparation of an integrated cloud-based electrochemical microcolumn platform

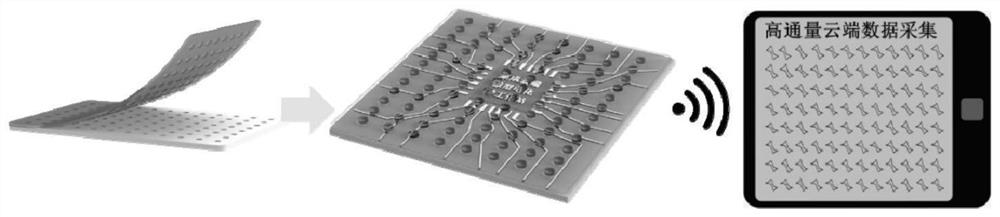

[0075] Micro-column platform preparation: such as figure 1 As shown, the cell microcolumn culture unit of polydimethylsiloxane (PDMS) with an array number of 12 × 8 was prepared by the template stripping method, and the prepolymer and the curing agent were mixed and poured on the array with a ratio of 10:1. On the template with holes, dry it in an oven at 80°C for 3 hours, and peel it off from the template after curing to obtain an arrayed micro-column platform. Mix a surfactant such as perfluorodecyltrichlorosilane with an adhesive After being coated on the surface of the microcolumn, the surface has a certain hydrophobic and organic properties after drying, and can be used to fix the medium for cell culture and real-time culture monitoring;

[0076] Integration of micro-columns and integrated workstations: Embedding a micro-droplet detection unit in each micro-column, using a n...

Embodiment 2

[0078] Example 2: Application of an integrated cloud-based electrochemical microcolumn platform

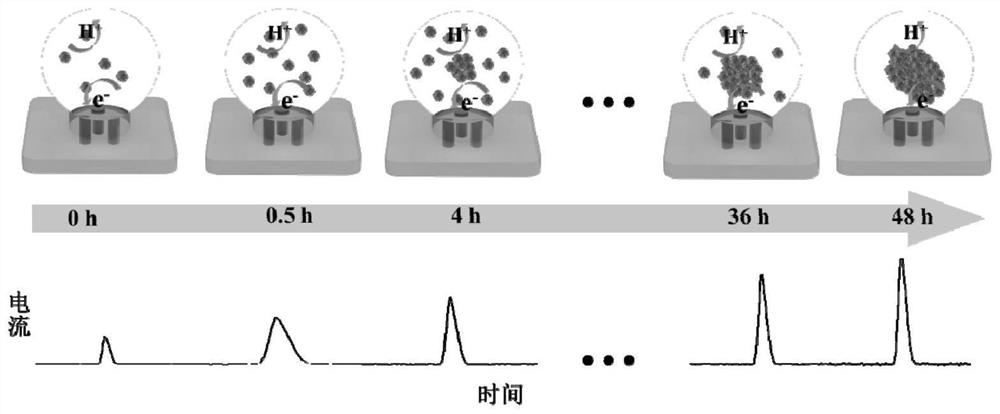

[0079] High-throughput cell real-time culture monitoring (current-time method):

[0080] On the cell microcolumn culture unit of the 12×8 array microcolumn, drop the culture medium containing the cells to form a micro droplet for cell culture, add 4-aminophenylphosphate sodium salt as an electrochemical signal agent, turn on the power, The integrated cloud electrochemical working unit is wirelessly connected to the data receiving and analyzing unit, and the integrated cloud electrochemical working unit converts the electrochemical signal detected by the micro droplet detection unit into a wireless signal, and transmits it to the data receiving and analyzing unit, namely a mobile phone or a computer On the mobile phone or computer, choose the current time method to analyze the received information, because the non-specific phosphatase of the cell membrane will oxidize the sodium sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com