Production equipment, production system and production process of glass fiber composite filter material

A glass fiber composite and production equipment technology, applied in the direction of synthetic cellulose/non-cellulose material pulp/paper, filter paper, filtration separation, etc., can solve the problems of reducing filter resistance, glass fiber filter material cracking, and yield reduction, etc. problems, achieve the effect of reducing energy consumption, reducing the pressure drop of filter media and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

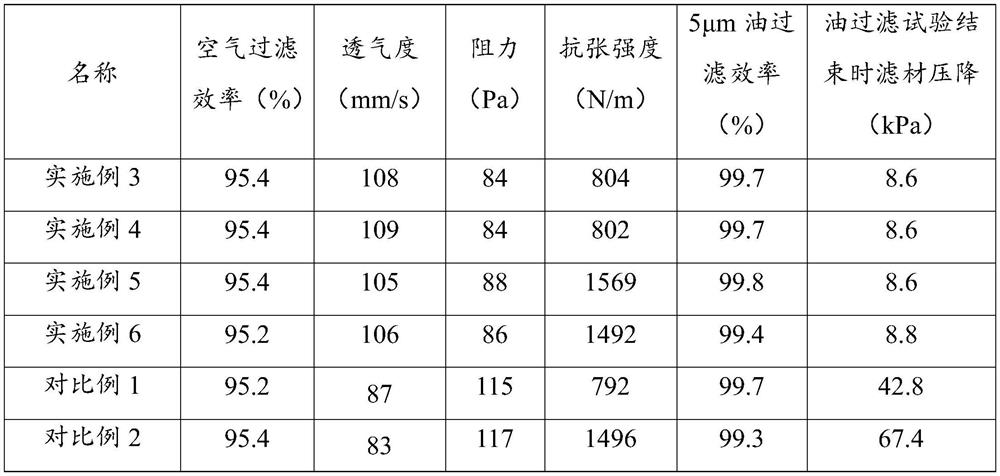

Examples

Embodiment 1

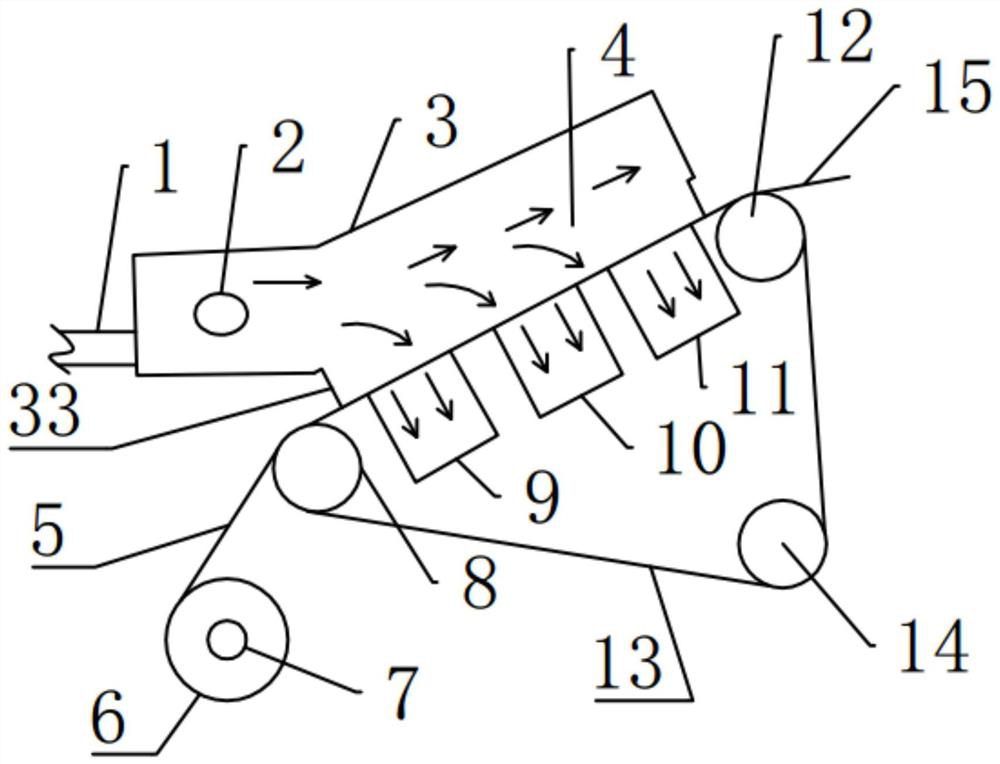

[0060] Such as figure 1 The production equipment of the shown glass fiber composite filter material comprises a headbox 3, a forming wire 13, a first unwinding roller 7, a first dewatering device and a driving mechanism, wherein the headbox 3 is used to provide a glass fiber filter for preparation. The fiber slurry required by the material.

[0061] One side of the headbox 3 is provided with a slurry inlet, and the bottom of the headbox is provided with a slurry outlet, and the headbox 3 is located at the slurry inlet and is connected with a slurry delivery pipeline 1, and the slurry delivery pipeline 1 is also It is connected with a slurry pump, and the fiber slurry flows into the headbox 3 through the slurry delivery pipeline 1 through the slurry pump.

[0062] The first dehydration device is closely attached to the lower surface of the forming net 13, and the forming net 13 is communicated with the slurry outlet, and the first dehydration device is communicated with the sl...

Embodiment 2

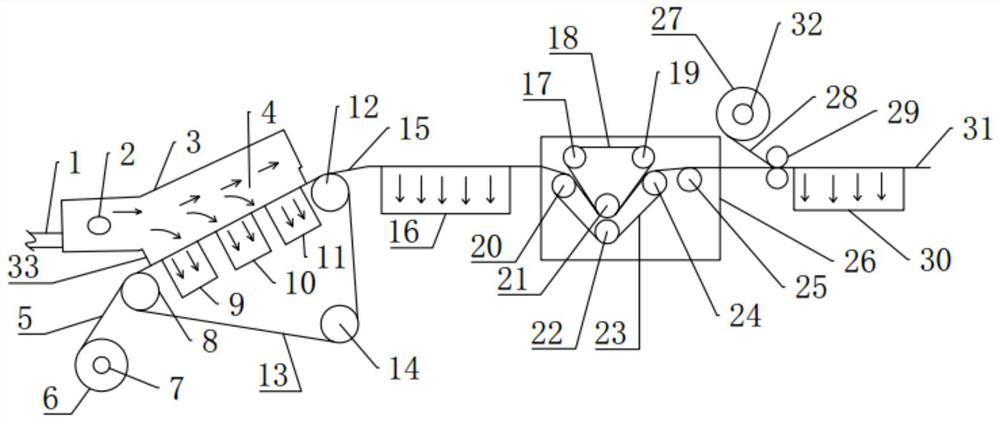

[0074] Such as figure 2 The production system of the glass fiber composite filter material shown, in addition to the production equipment of the glass fiber composite filter material in Example 1, also includes an impregnation device.

[0075] The dipping device of the present embodiment is a dipping machine 26, comprising a dipping tank for impregnating the glass fiber filter material and a clamping device arranged in the dipping tank, the clamping device includes an upper clamping net 18 and a lower clamping net 23, respectively surrounding On at least two impregnation driving rollers, there are three impregnation driving rollers in this embodiment, and the upper clamping net 18 and the lower clamping net 23 are arranged in an inverted triangle structure, which are respectively the fourth driving roller 17 and the fifth driving roller. 19, the sixth driving roller 20, the seventh driving roller 21, the eighth driving roller 22 and the ninth driving roller 24, there is a gap...

Embodiment 3

[0080] The present embodiment provides a kind of production technology of glass fiber composite filter material, adopts the production system of glass fiber composite filter material that embodiment 2 provides to make, comprises the following steps:

[0081] (1) Dispersing glass microfibers with a degree of beating of 39° in water, adjusting the pH value of the slurry to 3 using sulfuric acid to obtain a fiber slurry with a mass percentage of glass microfibers of 0.5%;

[0082] (2) Start the driving motor and the vacuuming device so that the first driving roller 8, the second driving roller 12 and the third driving roller 14 rotate, and simultaneously drive the polyester forming net 13 to rotate; drive the first unwinding roller 7 to rotate, and Non-woven fabric (air permeability of 1000mm / s, 50g / m 2 ) to the forming net 13, the non-woven fabric is flattened on the forming net 13, and advances with the rotation of the forming net 13; the slurry pump is started to make the fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com