Tobacco topping and bud inhibition integrated system based on unmanned aerial vehicle

A technology of unmanned aerial vehicles and tobacco, applied in agricultural machinery and tools, manipulators, motor vehicles, etc., can solve the problems of cumbersome operation, high production cost, and less research on tobacco topping machinery, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

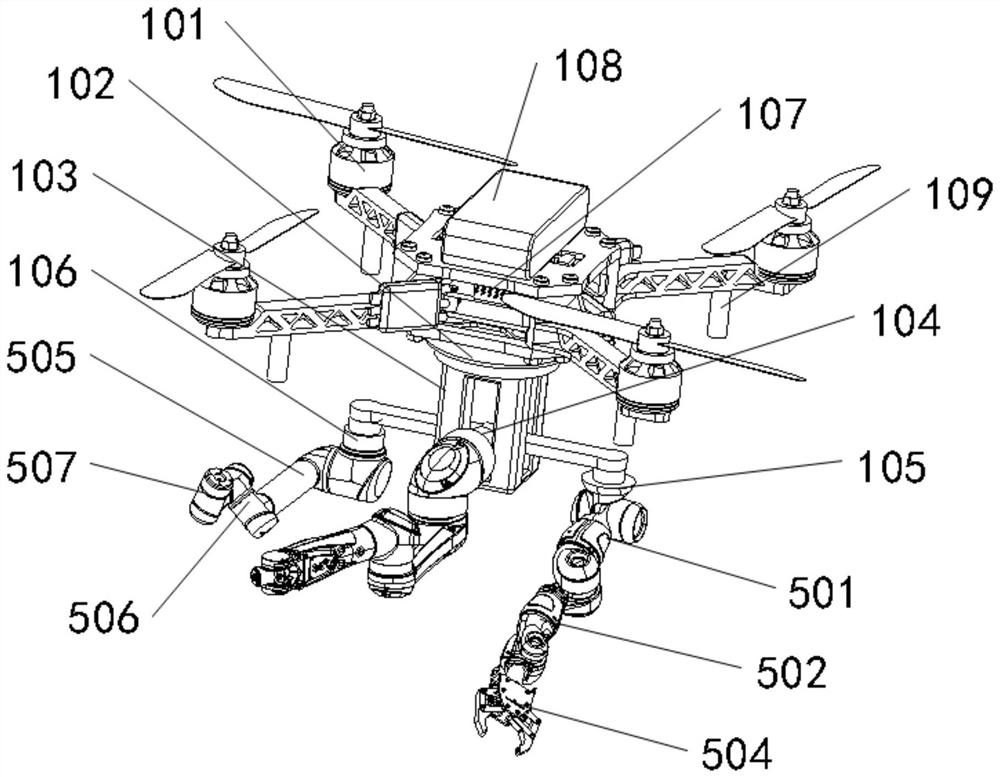

[0045] The first aspect of the present invention provides a tobacco topping and sprout suppression integrated system based on the drone 101, including the drone 101 and the medicine supply component installed on the drone 101;

[0046] Such as figure 1 As shown, the bottom of the drone 101 is provided with a rotating mechanism 102, the rotating mechanism 102 is connected with a lifting mechanism 103, and the lifting mechanism 103 is connected with a manipulator, and the manipulator is a multi-stage linkage structure. The lifting mechanism 103 is used to drive the manipulator to move.

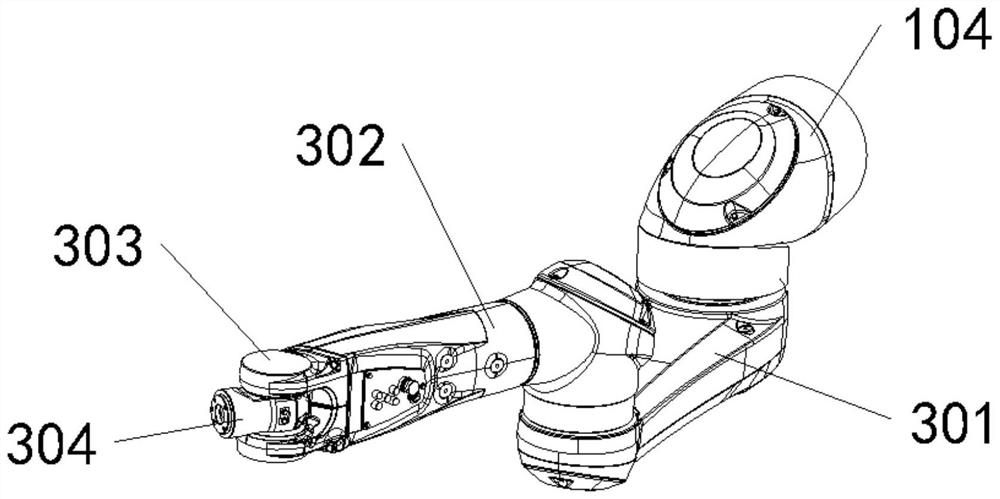

[0047] The manipulator includes a first manipulator 104, a second manipulator 105 and a third manipulator 106, the first manipulator 104 is arranged on the front of the lift mechanism 103, and the second manipulator 105 and the third manipulator 106 are respectively arranged on The two sides of the lifting mechanism 103 .

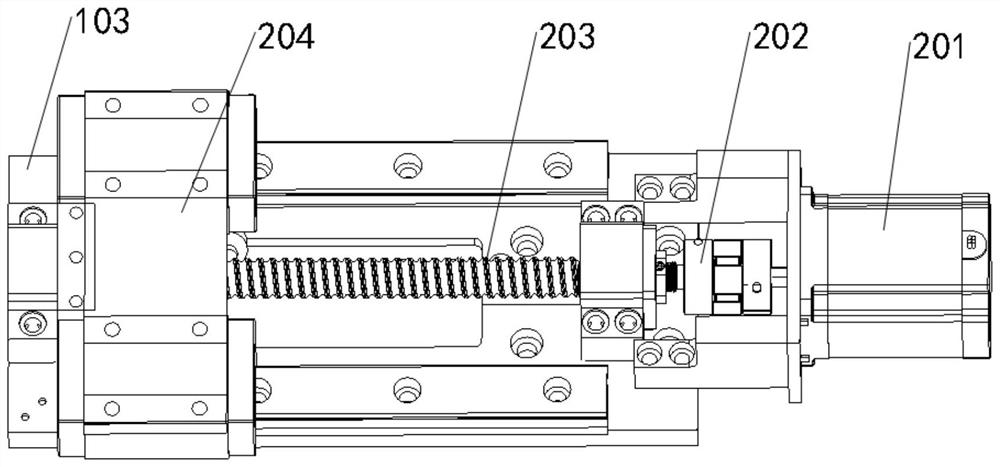

[0048] Such as figure 2 As shown, the lifting mechanism 103 is provi...

Embodiment 2

[0063] The second aspect of the present invention provides a control method for an integrated tobacco topping and bud suppression system based on a drone 101, which is applied to any one of the integrated tobacco topping and bud suppression systems based on a drone 101 system, such as Figure 7 As shown, it specifically includes the following steps:

[0064] S102: Acquire tobacco image information, and process the tobacco image information;

[0065] S104: By analyzing the image information of the tobacco, record the position point of the camera, and generate the position information of the calibration point;

[0066] S106: Establish a regional area model according to the location information, and obtain model information;

[0067] S108: Formulate a treatment plan according to the model information;

[0068] S110: Send the processing solution to the control terminal.

[0069] It should be noted that the camera mechanism 107 collects images of tobacco plants, and transmits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com