Wound surface liquid dressing and preparation method thereof

A wound surface liquid and system technology, which is applied to the preparation of several thousand words of wound liquid dressing, liquid dressing and its preparation field, can solve the problems that the Band-Aid film cannot meet the waterproofness and air permeability at the same time, the active ingredients are not clear, the formula is complicated, etc. Anti-inflammatory and healing effect, good breathability, simple formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1A

[0067] Embodiment 1A synthetic compound GA-C 28

[0068] 1. Accurately weigh gallic acid monohydrate (2.26g, 12.0mmol) and n-octacosanol (1.65g, 4.0mmol), and add them to a two-necked bottle with a water separator and a thermometer, wherein gallic acid and n-octacosanol The molar ratio of octacosanol is 3:1;

[0069] In the embodiment of the present invention, the molar ratio of gallic acid to n-octacosanol is 3:1 as an example, and other molar ratios (2-4.5):1 are also applicable to the present invention.

[0070] 2. Accurately measure 20.0mL (usually 15.0-35.0mL) of 1,4-dioxane solvent and add it to the two-necked bottle;

[0071] Usually the ratio of the amount of solvent to octacosanol is 9-22:1, that is, the liquid-solid ratio of solvent to octacosanol is 9-22:1, that is, the volume of solvent to the mass of octacosanol The ratio is 9-22:1, and every 1g of octacosanol is dissolved with 9-22ml of solvent; the liquid-solid ratio of the amount of solvent to gallic acid is...

Embodiment 1

[0084] Weigh a certain quality of bleached shellac, plasticizer PEG1k, GA-C 28 ; Mix bleached shellac, PEG1K, GA-C with stirring 28 Add to 15.0mL of absolute ethanol, stir and heat the mixture to 45°C (usually 35-50°C), and stir and mix for 2.5h (usually 2-4h) while maintaining the temperature at 45°C; then add 5.0mL The ethyl acetate dissolves the solid completely; after the mixed solution is naturally cooled to room temperature, the wound liquid dressing of the present invention is obtained;

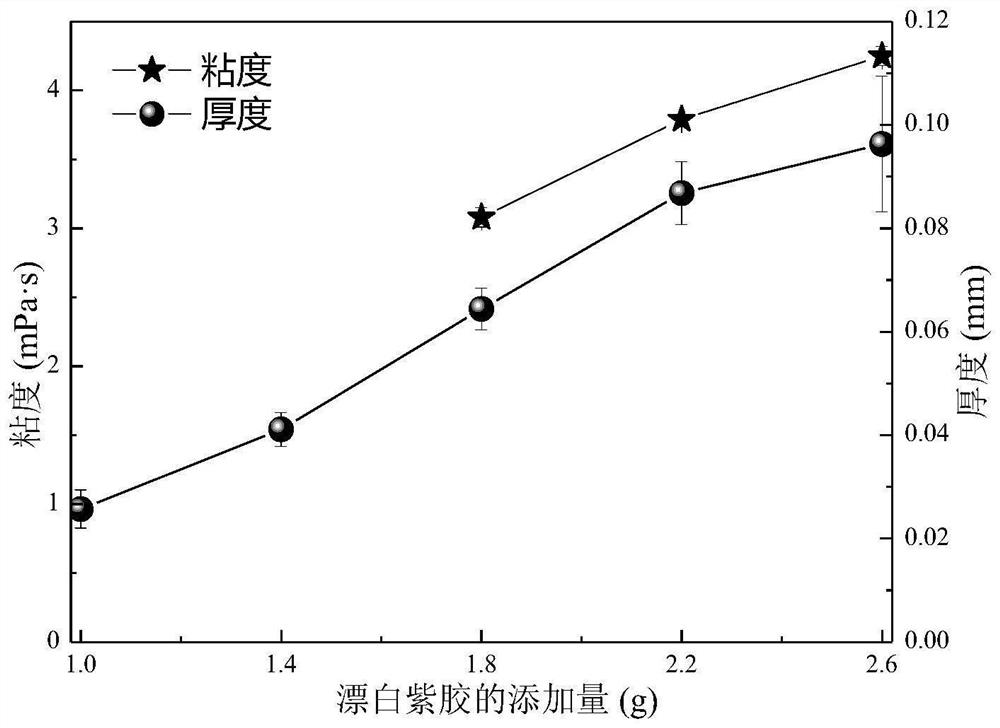

[0085] In the present embodiment, the addition amount of control plasticizer PEG1k is 0.40g, GA-C 28 The addition amount of 0.03g, and the addition amount of bleached shellac were 1.00, 1.40, 1.80, 2.20, 2.60g, respectively, to prepare 5 liquid wound dressing samples (named samples 1-5), and each treatment was repeated 3 times.

[0086] Use the NDJ-8S rotational viscometer (Shanghai Jingke Industrial Co., Ltd.) to measure the viscosity of the wound liquid dressing prepared in Example...

Embodiment 2

[0090] Weigh a certain quality of bleached shellac, plasticizer PEG1k, GA-C 28 ; Mix bleached shellac, PEG1K, GA-C with stirring 28 Add to 15.0mL of absolute ethanol, stir and heat the mixture to 45°C (usually 35-50°C), and stir and mix for 2.5h (usually 2-4h) while maintaining the temperature at 45°C; then add 5.0mL The ethyl acetate dissolves the solid completely; after the mixed solution is naturally cooled to room temperature, the wound liquid dressing of the present invention is obtained;

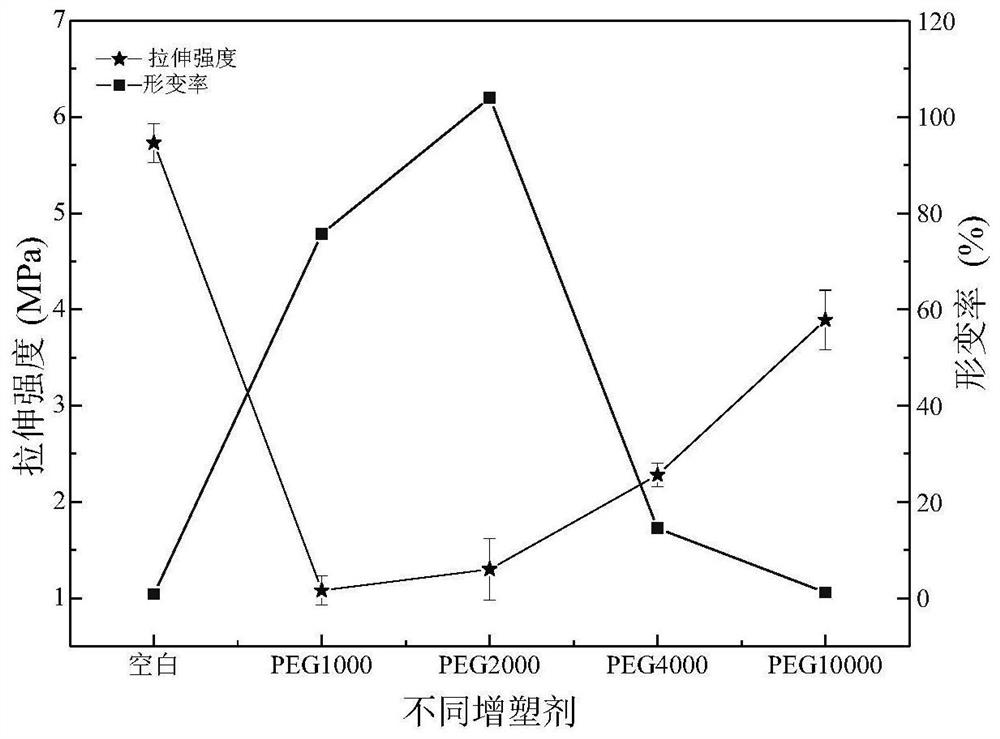

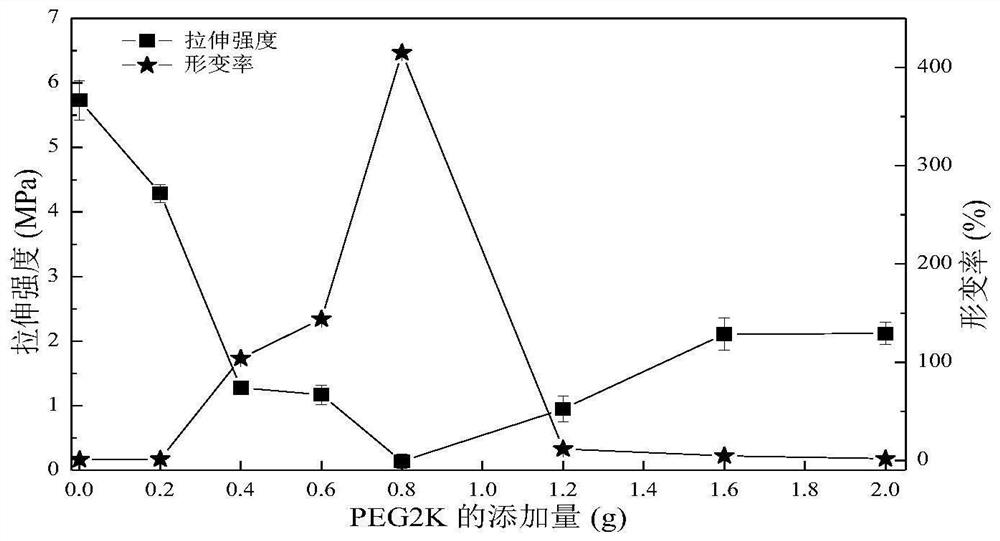

[0091] In the present embodiment, the addition amount of control bleaching shellac is 1.80g, GA-C 28 The addition amount of 0.03g, the addition amount of plasticizer is 0.40g, the plasticizer chooses PEG1k, PEG2k, PEG4k, PEG10k, PVA, PVP respectively, prepares 6 liquid dressing samples, each treatment repeats 3 times. The sample without plasticizer was set as blank control.

[0092] Accurately measure 5.0 mL each of the 6 liquid dressings prepared in Example 2, spread them on a 9.0 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com