Sewage treatment device based on electrochemical and biological filtration

A sewage treatment device and biological filtration technology, applied in the direction of electrochemical water/sewage treatment, filtration treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult water quality assurance, affecting the purification efficiency of sewage treatment, and poor sewage treatment effect and other problems, to achieve the effect of convenient automatic dumping, improved water inlet efficiency, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

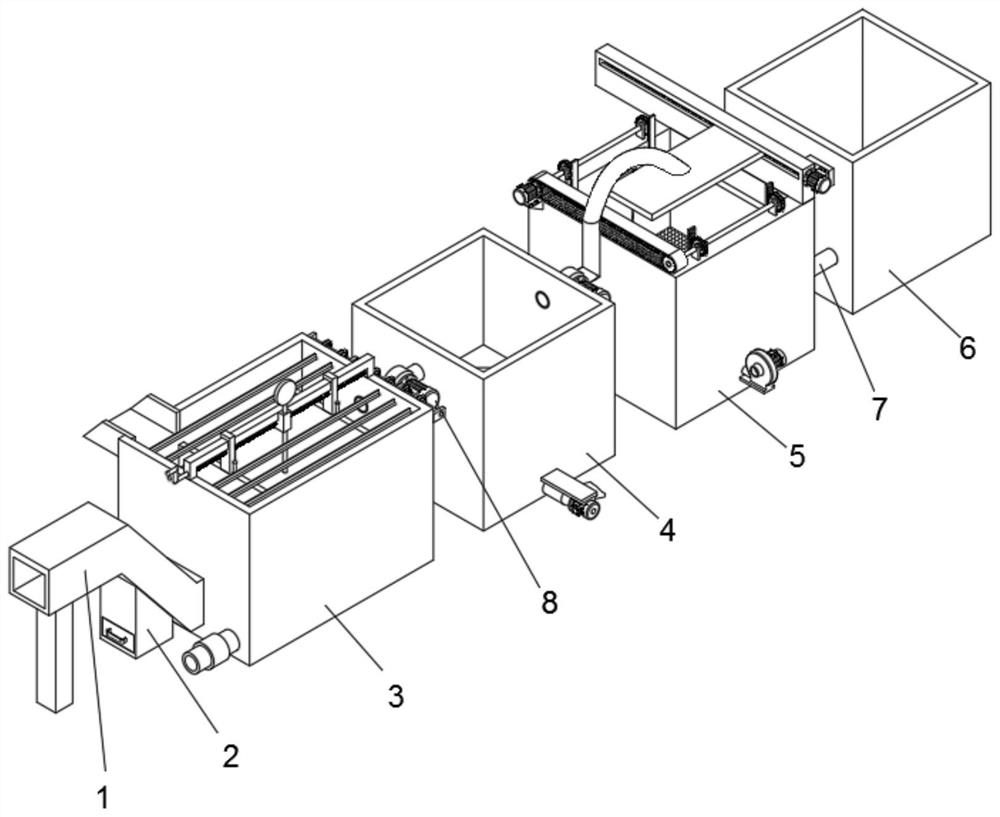

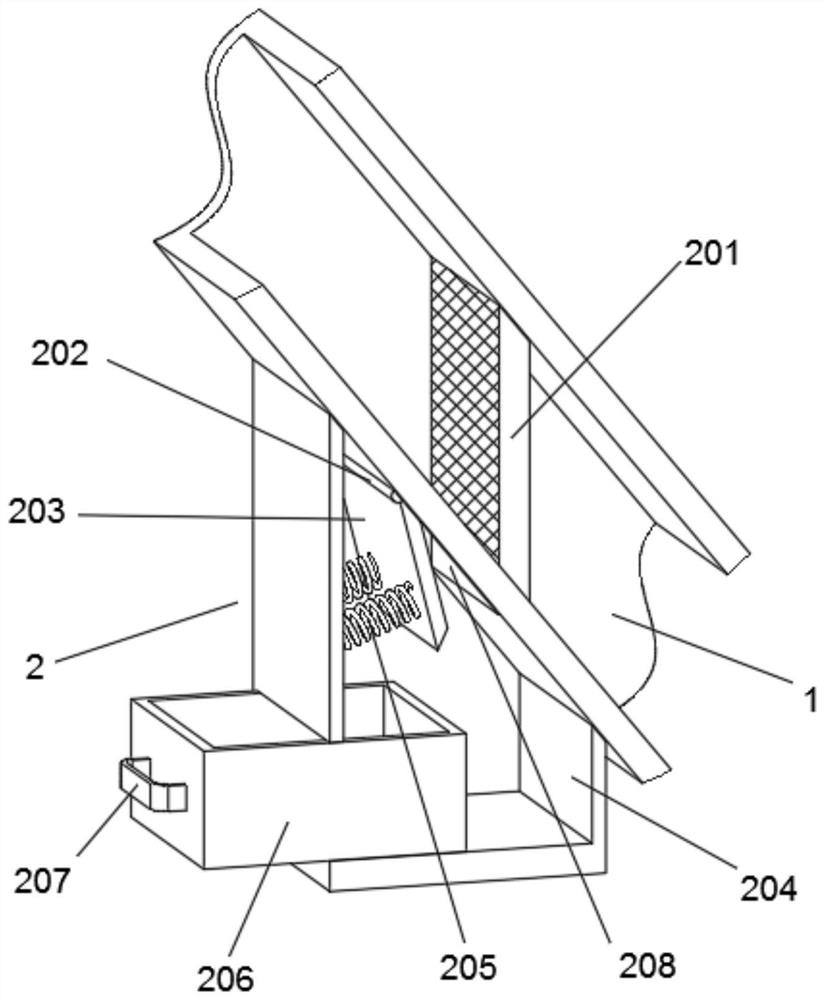

[0040] Such as Figure 1-2 As shown, a sewage treatment device based on electrochemical and biological filtration includes a water inlet pipe 1, the middle part of the water inlet pipe 1 is provided with a filter assembly 2, the right end of the water inlet pipe 1 is connected to an electrochemical reaction pool 3, and the right end of the electrochemical reaction pool 3 is provided with There is a sedimentation tank 4, the right end of the sedimentation tank 4 is provided with a biological filter 5, the right end of the biological filter 5 is provided with a clear water tank 6, the filter assembly 2 includes a filter screen 201, the outer wall of the middle part of the water inlet pipe 1 is provided with a through groove 208, and the left side of the through groove 208 The lower end of the wall is rotatably connected with a rotating rod 202, the inside of the through groove 208 is clamped with a stopper 203, the lower surface of the middle part of the water inlet pipe 1 is fix...

Embodiment 2

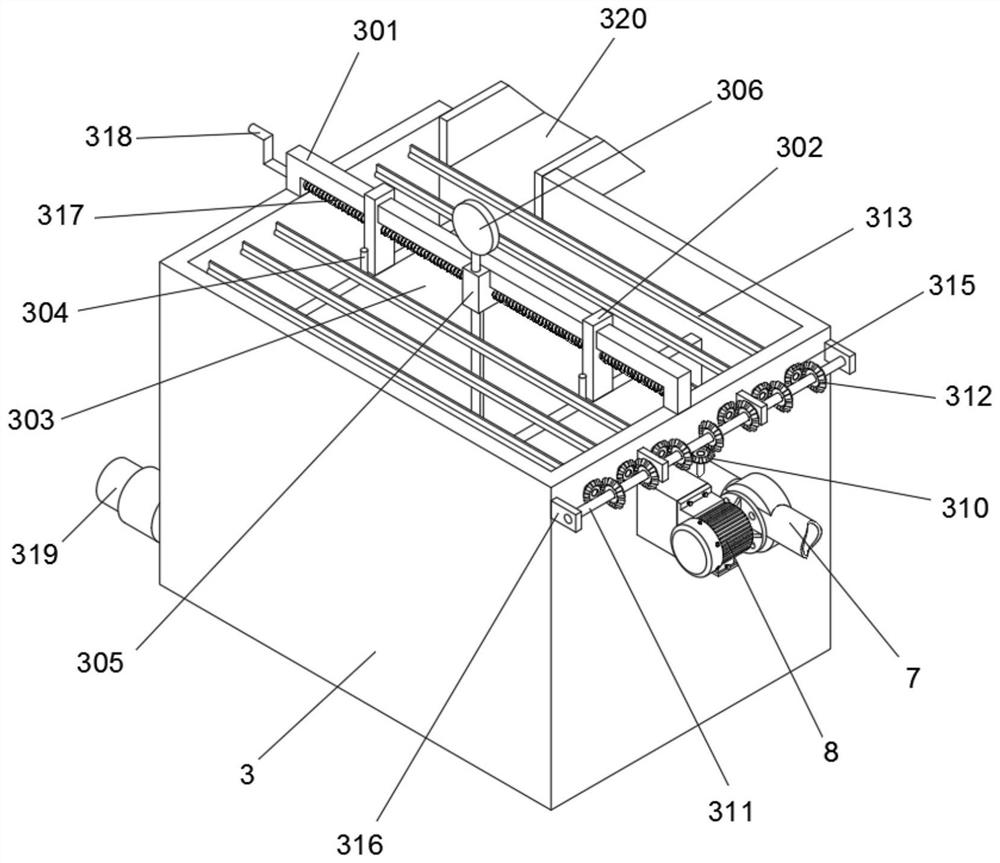

[0045] Such as Figure 3-5 As shown, on the basis of Embodiment 1, the electrochemical reaction cell 3 includes a C-shaped block 301, and two sliders 302 are slidably connected to the C-shaped block 301 in a left-right symmetrical structure, and the bottom surface of the slider 302 is fixed with a pole plate 303 , the front end of the top surface of the pole plate 303 is fixed with a terminal 304, and the middle part of the C-shaped block 301 is fixed with a fixed block 305. The fixed block 305 is sleeved with a voltmeter 306. The left end of the screw rod 317 is coaxially connected with a rocker 318, the slide block 302 is threadedly connected with the two-way screw rod 317 through a threaded hole, and the two-way screw rod 317 is rotationally connected with the fixed block 305. The pole plate 303 is an anode plate, and the pole plate 303 at the right end is a cathode plate. The lower end of the left wall of the electrochemical reaction tank 3 is connected with a sewage pipe ...

Embodiment 3

[0049] Such as Figure 6-7 As shown, on the basis of Embodiment 2, a tapered groove 401 is provided on the inner bottom surface of the sedimentation tank 4, and the front end of the tapered groove 401 is connected with a discharge pipe 402, and the inside of the discharge pipe 402 is provided with an auger 403. The wall is fixed with a disk ring gear 404, the middle of the tapered groove 401 is provided with a sleeve 405, the middle of the sleeve 405 is rotatably connected with a cylinder 406, the upper end of the cylinder 406 is sleeved with a gear A409, and the upper end of the cylinder 406 extends through the inner wall of the sleeve 405 To the outside and fixed with a scraper 407, the lower end of the front surface of the sedimentation tank 4 is installed with a motor A408 through the mounting seat, the disc ring gear 404 is meshed with the gear A409, and the scraper 407 is in frictional contact with the tapered groove 401. The scraper 407 is The inclined structure, the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com