High-resolution scintillator film, preparation method, preparation equipment and application

A high-resolution, scintillator technology, applied in the field of high-resolution X-ray imaging, can solve the problems of low radiation luminous intensity and uneven scintillator film, so as to improve the resolution, increase the radiation luminous intensity, and improve the uniformity of texture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

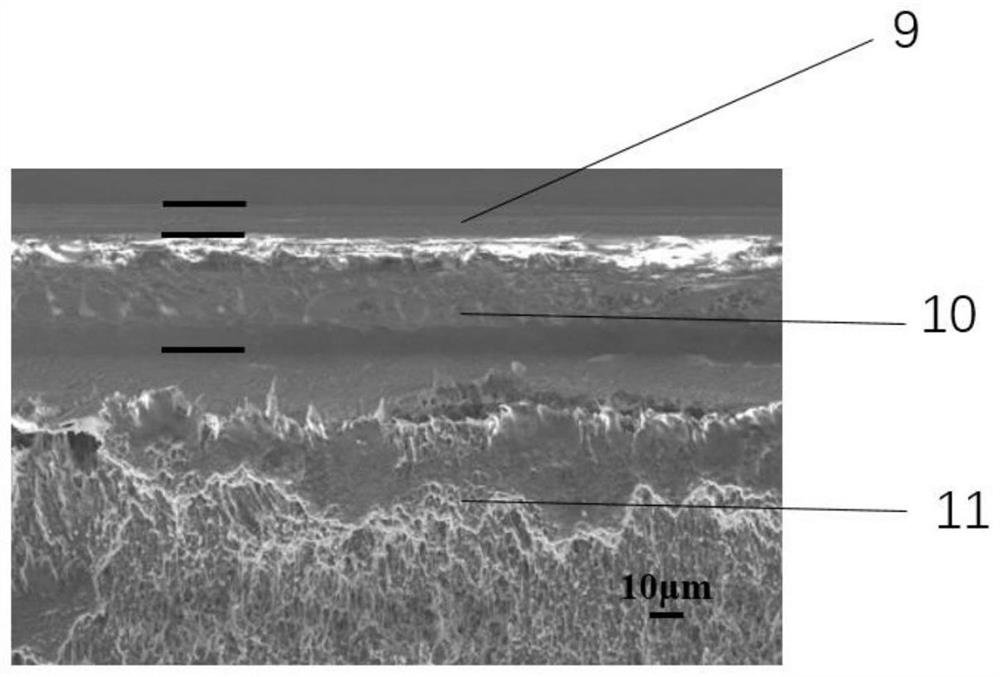

[0057] In view of the above-mentioned technical problems, the present invention proposes a method for preparing a high-resolution scintillator thin film, comprising the following steps:

[0058] Step 1. Prepare scintillator dispersion system.

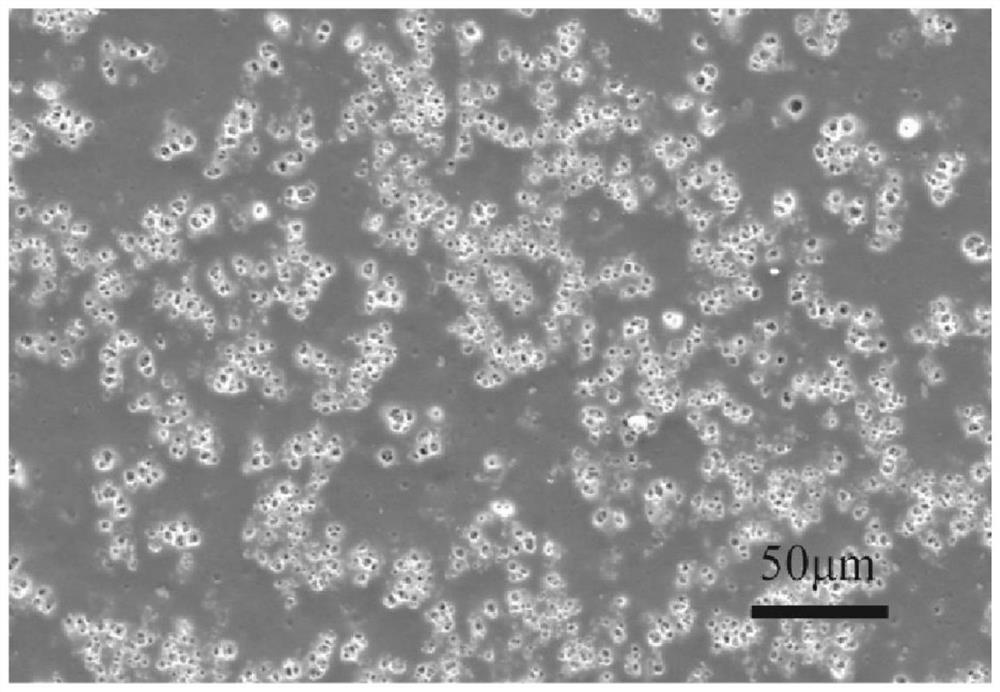

[0059] In an embodiment of the present invention, the scintillator is a perovskite scintillator, including: CsPbBr 3 , CsPbBr 3 +PPO (diphenyloxazole), CsPbBr 3 : Ce 3+ , the scintillator concentration in the scintillator dispersion system is positively correlated with the thickness of the scintillator layer.

[0060] In the embodiment of the present invention, CsPbBr 3 The preparation method comprises the following steps:

[0061] Step 1: Prepare a precursor solution using octadecene, cesium carbonate, and oleic acid.

[0062] The second step: using octadecene, oleic acid, oleylamine and lead bromide to prepare a lead ion solution.

[0063] The third step: adding the precursor solution to the above-mentioned lead ion solution to...

Embodiment 1

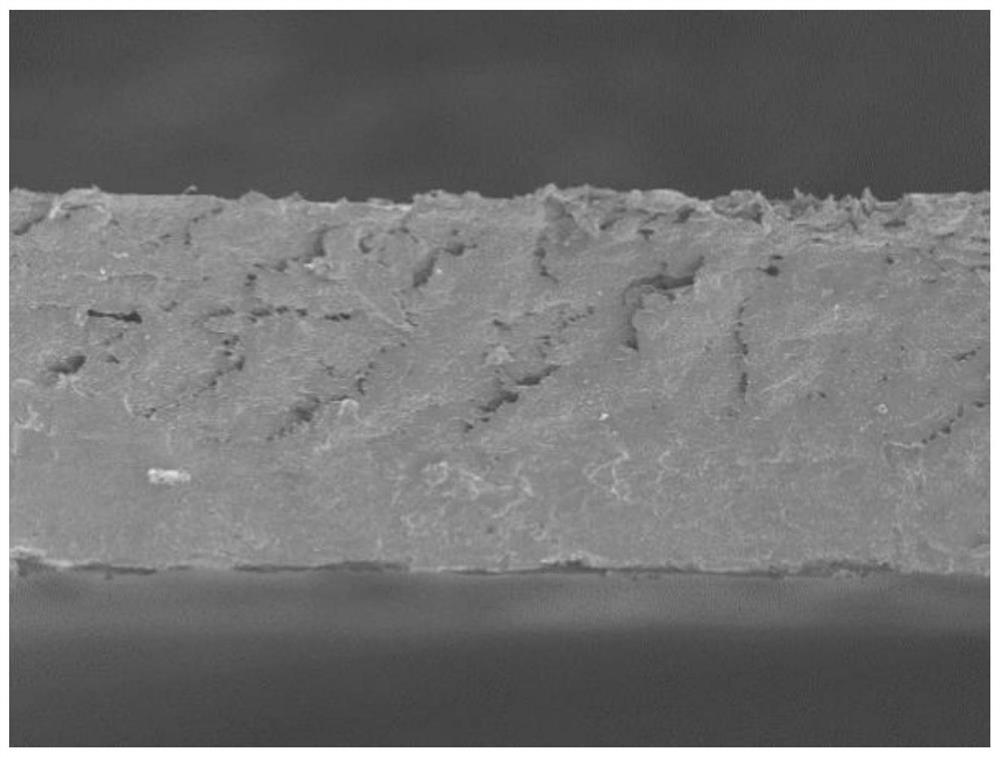

[0086] Preparation of CsPbBr 3 Scintillator thin film, its specific preparation steps are as follows:

[0087] Step 1: first use absolute ethanol and pure water to rinse the upper bottle 3 and the volumetric flask 6 of suction filtration, select the volumetric flask 6 with a sand core diameter of 20mm, rinse it and put it in a 70-degree oven to dry the instrument, before film making , at first ensure that there is no moisture and ethanol in the suction filter upper bottle 3 and the volumetric flask 6.

[0088] Step 2: Weigh 500 mg of polystyrene, dissolve it in 10 ml of toluene, and prepare a 50 mg / ml polystyrene toluene solution.

[0089] Step 3: Rinse the upper bottle 3 of suction filtration with toluene for three times, and place a smooth, non-scratched polyvinylidene fluoride membrane 5 with a size of 25mm×25mm and a pore size of 200nm on the upper suction filtration bottle 3 and volumetric flask 6 In between, clamp the upper suction filtration bottle 3 and the volumetric ...

Embodiment 2

[0095] Preparation of CsPbBr 3 +PPO scintillator film, the specific preparation steps are as follows:

[0096] Step 1: first use absolute ethanol and pure water to rinse the upper bottle 3 and the volumetric flask 6 of suction filtration, select the volumetric flask 6 with a sand core diameter of 20mm, rinse it and put it in a 70-degree oven to dry the instrument, before film making , at first ensure that there is no moisture and ethanol in the suction filter upper bottle 3 and the volumetric flask 6.

[0097] Step 2: Weigh 500 mg of polystyrene and 700 mg of PPO respectively, dissolve them in 10 ml of toluene respectively, and configure 50 mg / ml polystyrene toluene solution and 70 mg / ml PPO toluene solution.

[0098] Step 3: Rinse the upper bottle 3 of suction filtration with toluene for three times, and place a smooth, non-scratched polyvinylidene fluoride membrane 5 with a size of 25mm×25mm and a pore size of 200nm on the upper suction filtration bottle 3 and volumetric fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com