Method for recovering valuable metal from positive electrode material containing binder and valuable metal

A cathode material and valuable metal technology, applied in the field of lithium-ion batteries, can solve the problems of high cost, the need for matching organic solvent recovery facilities, the installation of matching waste gas treatment facilities, the viscosity of organic solvents, etc., to achieve easy promotion, inhibition of high temperature decomposition, The effect of mature equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

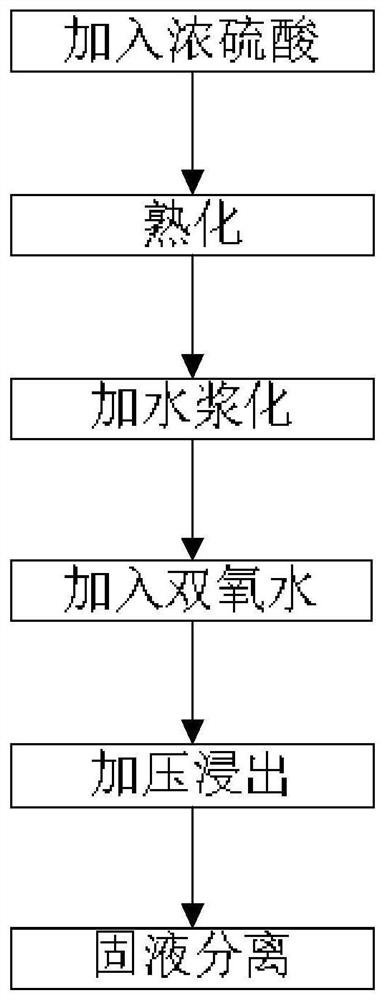

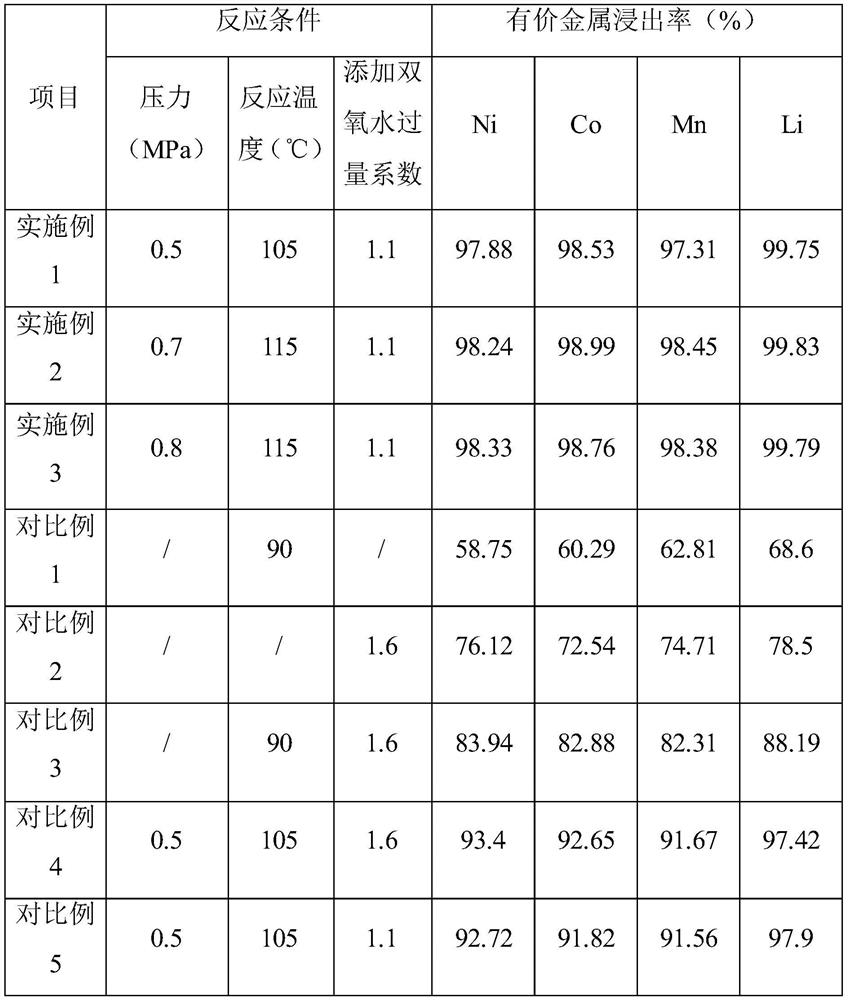

[0072] see figure 1 , the present embodiment provides a method for recovering valuable metals from a positive electrode material containing a binder, which specifically includes the following steps:

[0073] 1) Weigh 100.13g of the above powder and place it in a reaction kettle, add 65mL of concentrated sulfuric acid at a flow rate of 0.78L / h while stirring and mix evenly (wet mud).

[0074] 2) Close the reaction kettle, raise the temperature to 105°C and let stand for 2h.

[0075] 3) Turn off the heating and turn on the stirring, add 550mL of pure water for slurrying, in the system after slurrying, the concentration of concentrated sulfuric acid is 2mol / L, and the liquid-solid ratio is 6ml:1g;

[0076] Then add 50g of 30wt% hydrogen peroxide, pass nitrogen gas to exhaust the air in the reactor and adjust the pressure of the reactor to 0.5MPa, then start to heat up, heat up to 105°C, and keep the reaction for 2h.

[0077] 4) After the reaction is completed, the temperature o...

Embodiment 2

[0080] This embodiment provides a method for recovering valuable metals from a positive electrode material containing a binder, which specifically includes the following steps:

[0081] 1) Weigh 200.28g of the above powder and place it in a reaction kettle, add 135mL of concentrated sulfuric acid at a flow rate of 0.8L / h while stirring and mix evenly (wet mud).

[0082] 2) Close the reaction kettle, raise the temperature to 105°C and let stand for 2h.

[0083] 3) Turn off the heating and turn on the stirring, add 950mL pure water for slurrying, in the system after slurrying, the concentration of concentrated sulfuric acid is 2.4mol / L, and the liquid-solid ratio is 5.25ml:1g;

[0084] Then 104g of 30wt% hydrogen peroxide was added, nitrogen gas was introduced to exhaust the air in the reactor, and the pressure of the reactor was adjusted to 0.7MPa, then the temperature was raised, and the temperature was raised to 115° C., and the reaction was kept for 2 hours.

[0085] 4) Aft...

Embodiment 3

[0088] This embodiment provides a method for recovering valuable metals from a positive electrode material containing a binder, which specifically includes the following steps:

[0089] 1) Weigh 200.61g of the above powder and place it in a reaction kettle, add 135mL of concentrated sulfuric acid at a flow rate of 0.8L / h while stirring and mix evenly (wet mud).

[0090] 2) Close the reaction kettle, raise the temperature to 120°C and let it stand for 1 hour.

[0091] 3) Turn off the heating and turn on the stirring, add 950mL pure water for slurrying, in the system after slurrying, the concentration of concentrated sulfuric acid is 2.4mol / L, and the liquid-solid ratio is 5.25ml:1g;

[0092] Then 104g of 30wt% hydrogen peroxide was added, nitrogen gas was introduced to exhaust the air in the reactor, and the pressure of the reactor was adjusted to 0.8MPa, then the temperature was raised, and the temperature was raised to 115° C., and then the reaction was kept for 2 hours.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com