Preparation method and preparation device of nickel nitride supported by black phosphorus-graphene heterojunction

A preparation device and nickel nitride technology, which are applied in the preparation of phosphorus, graphene, chemical instruments and methods, etc., can solve the problems of low production efficiency, unenvironmental protection, and high cost, and achieve the reduction of raw material cost, uniform distribution, and good electricity. The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of black phosphorus-graphene heterojunction loaded nickel nitride, comprising the following steps:

[0048] S1) Weigh red phosphorus powder and cellulose powder respectively, disperse them in deionized water, and perform ultrasonic treatment to obtain a dispersion containing red phosphorus-cellulose complexes;

[0049] S2) adding nickel nitride particles to the dispersion liquid to form a mixed solution, stirring, putting the stirred mixed solution into a vacuum oven and drying to constant weight to obtain a mixture;

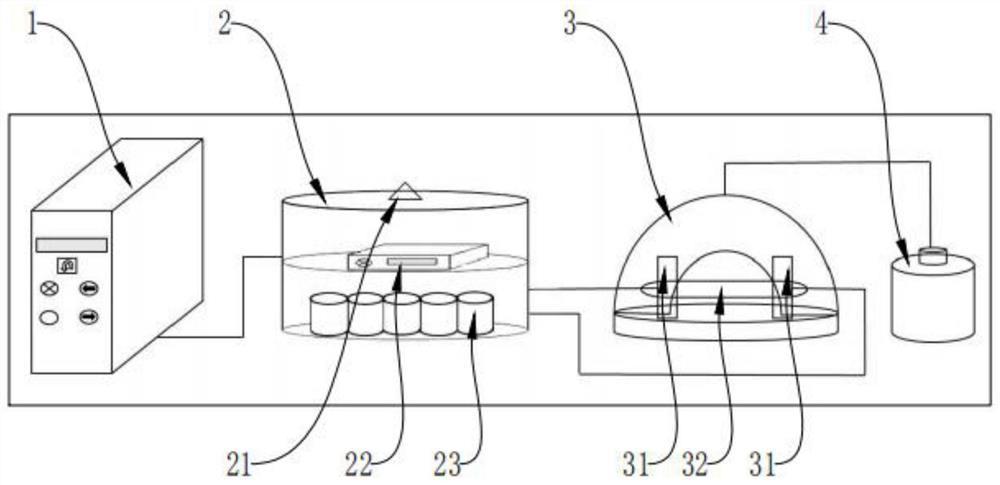

[0050] S3) Put the mixture into the high-voltage discharge chamber 3, and undergo high-voltage discharge processing to obtain a crude product;

[0051] S4) Dispersing the crude product in absolute ethanol, pouring it into a centrifuge tube, and then putting it into a centrifuge for centrifugal purification to form a refined product, and then putting the purified refined product into a vacuum oven to dry to constant weight, namely Bla...

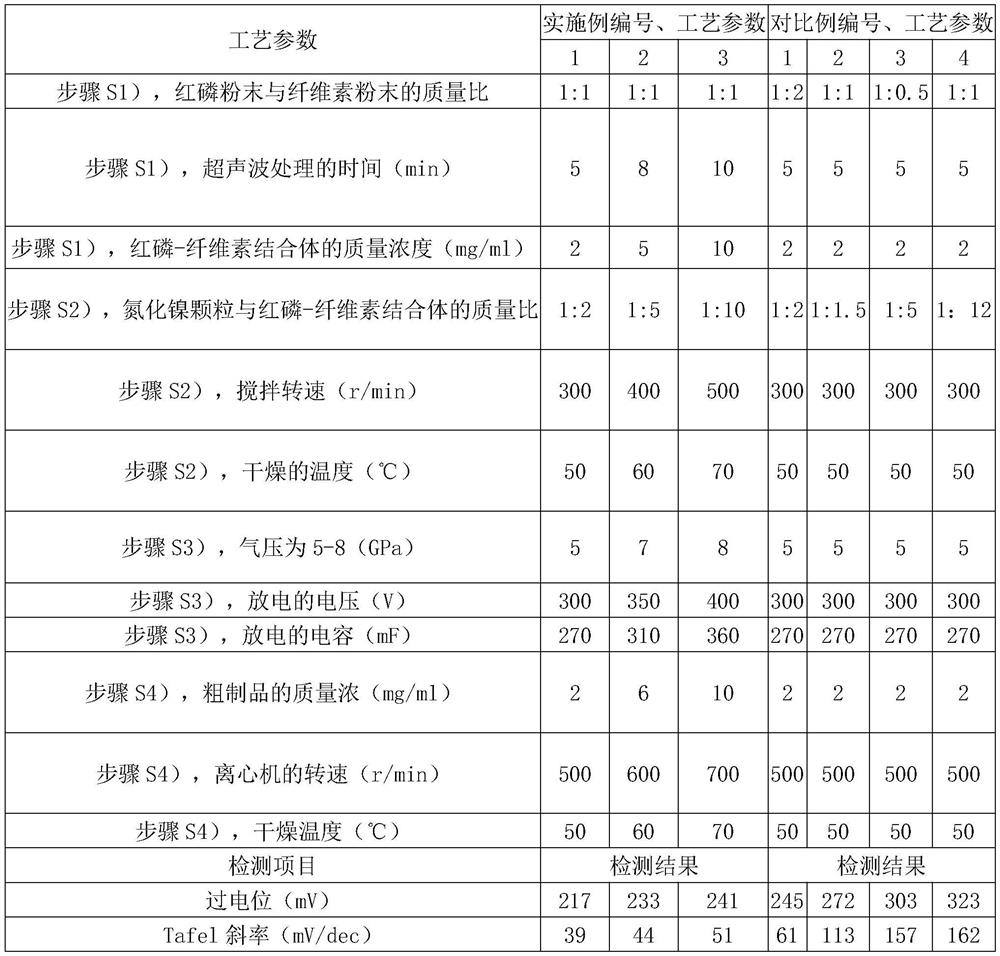

Embodiment 1-3 and comparative example 1-4

[0095] 1. The black phosphorus-graphene heterojunction loaded nickel nitride of each embodiment and each comparative example is prepared according to the following steps:

[0096] S1) Weigh red phosphorus powder and cellulose powder respectively, disperse them in deionized water, and perform ultrasonic treatment to obtain a dispersion containing red phosphorus-cellulose complexes;

[0097]S2) adding nickel nitride particles to the dispersion liquid to form a mixed solution, stirring, putting the stirred mixed solution into a vacuum oven and drying to constant weight to obtain a mixture;

[0098] S3) Put the mixture into the high-voltage discharge chamber 3, and undergo high-voltage discharge processing to obtain a crude product;

[0099] S4) Dispersing the crude product in absolute ethanol, pouring it into a centrifuge tube, and then putting it into a centrifuge for centrifugal purification to form a refined product, and then putting the purified refined product into a vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com