Preparation method of super-hydrophilic/underwater super-oleophobic separation membrane

An underwater super-oleophobic and super-hydrophilic technology, which is applied in osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problem of low water flux, short service life and complicated preparation process and other problems, to achieve the effect of high separation efficiency, no toxic and harmful substances, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

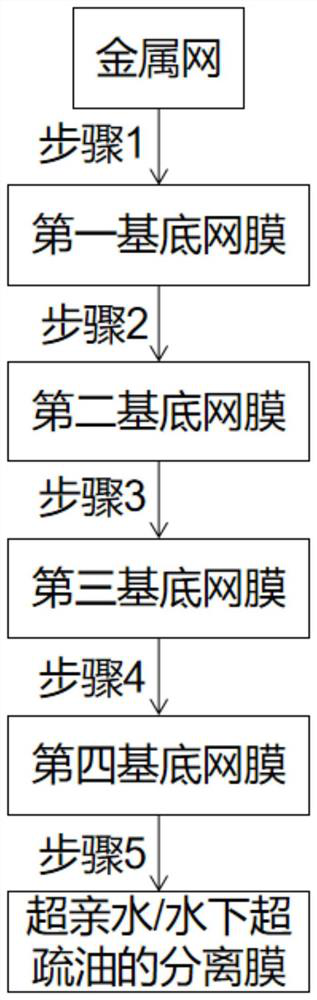

[0031] Embodiment one: if Figure 1-4 Shown, a kind of preparation method of superhydrophilic / underwater superoleophobic separation membrane comprises the steps:

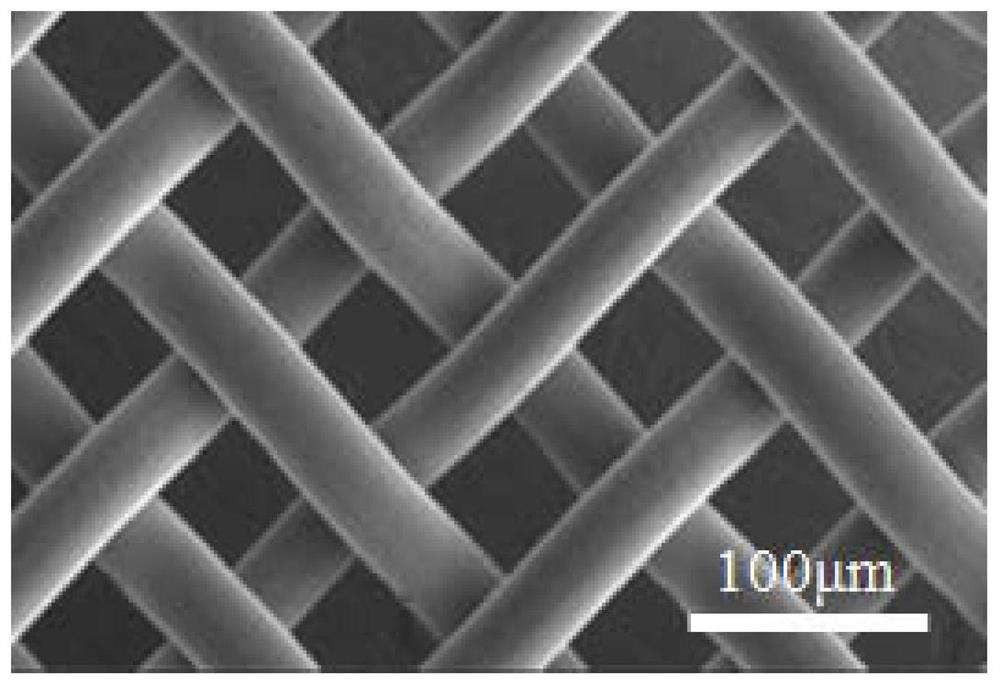

[0032] (1) The 300-mesh stainless steel mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes, and then dried to obtain the first basal omentum;

[0033] (2) Immerse the first basal omentum in an aqueous solution (40ml) of ammonium fluotitanate (0.9892g) and boric acid (0.617g), react at a constant temperature at 30°C for 10h in a water bath, take it out and use a deionized After washing with water, the second basal omentum was obtained after drying in air;

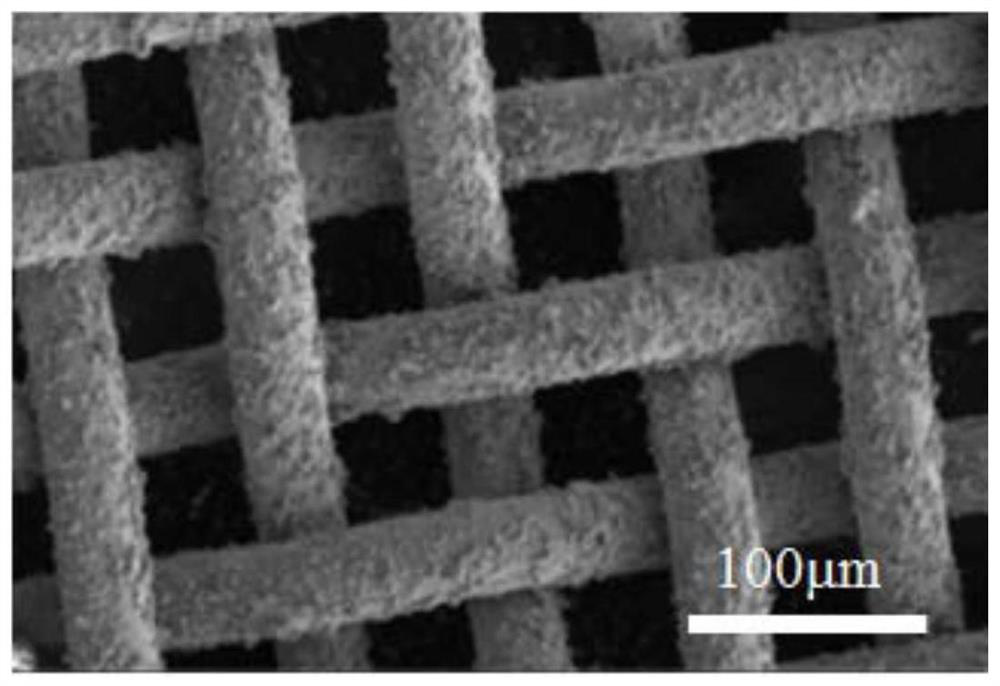

[0034] (3) Put the second basal omentum into a muffle furnace for heating and calcining, the heating rate is 2°C / min, the terminal temperature is 400°C, and the holding time is 2h. After the calcination is finished, take out the third base omentum supported by titania;

[0035] (4) Soak the third basal omentum in 20 ml of ...

Embodiment 2

[0037] Embodiment two: a kind of preparation method of superhydrophilic / underwater superoleophobic separation membrane comprises the following steps:

[0038] (1) The 300-mesh stainless steel mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes, and then dried to obtain the first basal omentum;

[0039] (2) Immerse the first basal omentum in an aqueous solution (40ml) of ammonium fluotitanate (0.988g) and boric acid (0.625g), react at a constant temperature at 30°C for 10h in a water bath, take it out and use a deionized After washing with water, the second basal omentum was obtained after drying in air;

[0040] (3) The second basal omentum is put into a muffle furnace for calcination, the program is set to a heating rate of 2°C / min, a terminal temperature of 400°C, and a holding time of 2h. After the calcination is finished, take out the third base omentum supported by titania;

[0041] (4) Soak the third basal omentum in 20 ml of 3vol%...

Embodiment 3

[0043]Embodiment three: a kind of preparation method of superhydrophilic / underwater superoleophobic separation membrane comprises the following steps:

[0044] (1) The 200-mesh stainless steel mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 20 minutes, and then dried to obtain the first basal omentum;

[0045] (2) Immerse the first basal omentum in an aqueous solution (40ml) of ammonium fluotitanate (0.9895g) and boric acid (0.613g), react at a constant temperature at 30°C for 10h in a water bath, take it out and use a deionized After washing with water, the second basal omentum was obtained after drying in air;

[0046] (3) The second basal omentum is put into a muffle furnace for calcination, the program is set to a heating rate of 2°C / min, a terminal temperature of 400°C, and a holding time of 2h. After the calcination is finished, take out the third base omentum supported by titania;

[0047] (4) Soak the third basal omentum in 20ml of 3vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com