Composite multi-layer network film based on sodium titanate nano wire and cobaltosic oxide nanoneedle, as well as preparation method and application thereof

A nano- and multi-layer network technology of cobalt trioxide, applied in chemical instruments and methods, separation methods, membranes, etc., can solve the problems of poor separation efficiency and permeation flux, and achieve low cost, good reusability, and ultra-high cycle efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one: the preparation of cobalt trioxide nano-needle net, concrete steps are as follows:

[0042] The stainless steel mesh (6 × 6 cm 2 ) were sonicated with acetone, ethanol, and 1 M HCl solution for 10 min and washed with deionized (DI) water, and then the stainless steel mesh was dried under vacuum. Take 0.58 g of Co (NO 3 ) 2 ·6H 2 O, 0.3 g NH 4 F and 0.6 g of urea were dissolved in 40 ml of deionized water, and magnetically stirred for 10 minutes to obtain a cobalamin mixture.

[0043] Place the cleaned stainless steel mesh vertically in the center of the 50 ml reaction kettle. The cobalamin mixture was poured into the autoclave. The autoclave was then heated to 120°C for 9 hours. After the reaction, the obtained pink mesh was taken out from the autoclave, rinsed with deionized water and ethanol, and dried naturally. Finally, the pink mesh was calcined in a muffle furnace at 400°C for 4 hours, and the mesh turned from pink to black.

[0044] attache...

Embodiment 2

[0045] Embodiment two: the preparation of ultra-long sodium titanate nanowires, the specific steps are as follows:

[0046] Dissolve 16 g NaOH in 40 mL DI water, and dissolve 0.27 g nano-TiO 2 (P25) Disperse the powder in NaOH solution and continue to stir for 20 minutes; then pour the uniformly dispersed solution into a 50mL autoclave. Then put it into a silicone oil bath at 130° C. and keep stirring for 24 hours. After the reaction, the autoclave was cooled to room temperature under continuous stirring. The finally obtained nanowires were washed with deionized water until the pH was 7, and sodium titanate nanowires in deionized water were obtained by centrifugation. Store the sodium titanate nanowires in 150 mL of deionized water.

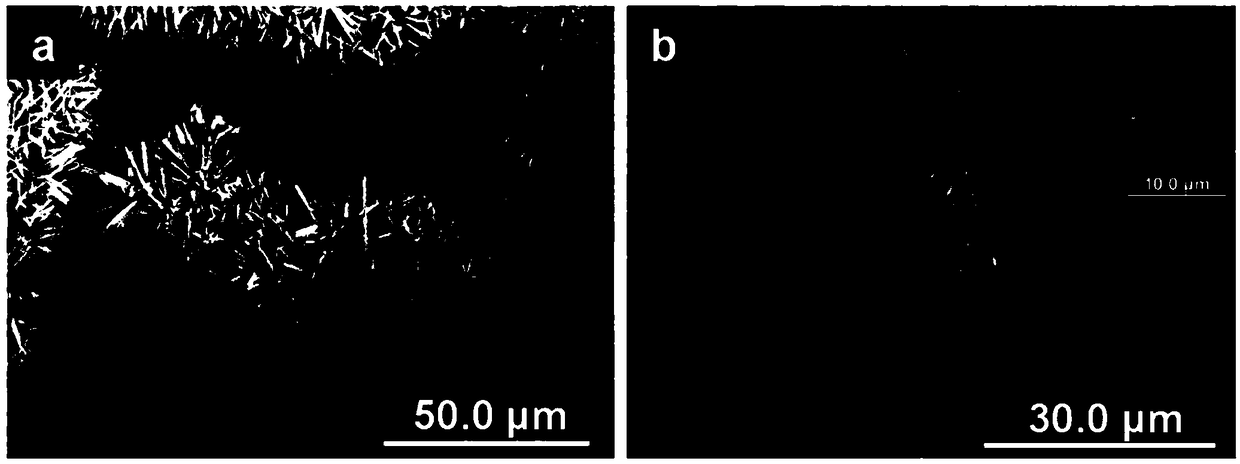

[0047] attached figure 2 It is a scanning electron microscope picture of sodium titanate nanowires. The length, thickness and distribution of the nanowires can be seen from the picture. These nanowires are interwoven to form a three-dimensio...

Embodiment 3

[0048] Embodiment three: The preparation of the composite multilayer network film based on sodium titanate nanowire and cobalt tetraoxide nanoneedle, concrete steps are as follows:

[0049] Fix the cobalt tetraoxide nanoneedle net on the sand core filter device. Take 3mL sodium titanate nanowire stock solution and evenly disperse in 300ml deionized water. Vacuum filter the homogeneously dispersed nanowire aqueous solution onto the surface of the cobalt trioxide nanoneedle mesh. The composite membrane (diameter: 4 cm) was then washed several times with deionized water. The film was dried in a vacuum desiccator at 60° C. to obtain a composite multilayer network film based on sodium titanate nanowires and cobalt tetraoxide nanoneedles.

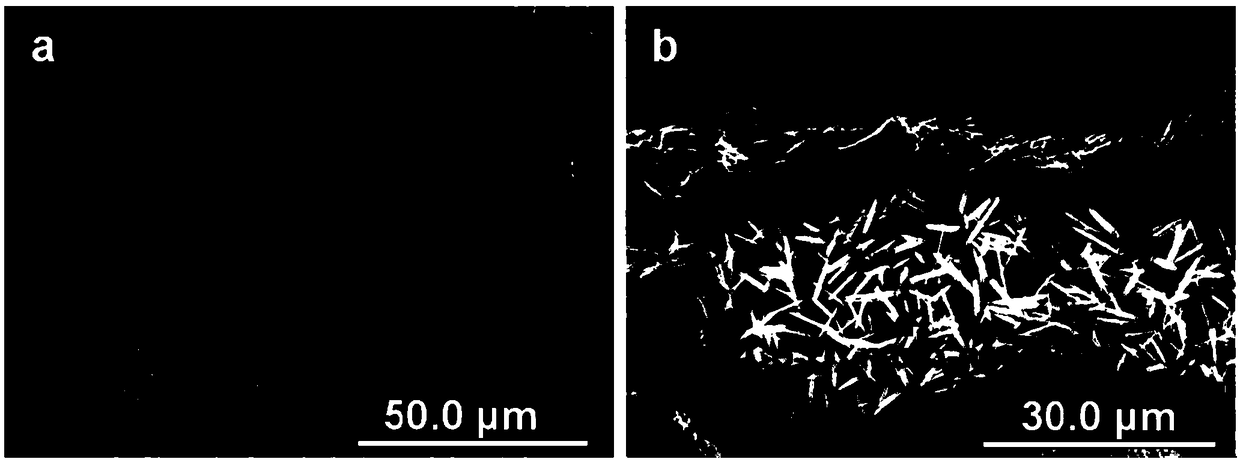

[0050] attached image 3 It is the SEM picture of the above-mentioned multilayer network composite film. The surface morphology and multi-layer distribution of the composite film can be seen through the picture. In figure a, it can be seen tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com