Polyurethane pouring sealant and preparation method thereof

A technology of potting glue and polyurethane, which is applied in the field of polyurethane materials, can solve the problems of difficult peeling and unsatisfactory low-temperature curing speed, and achieve the effects of fast low-temperature curing speed, good flame retardancy, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

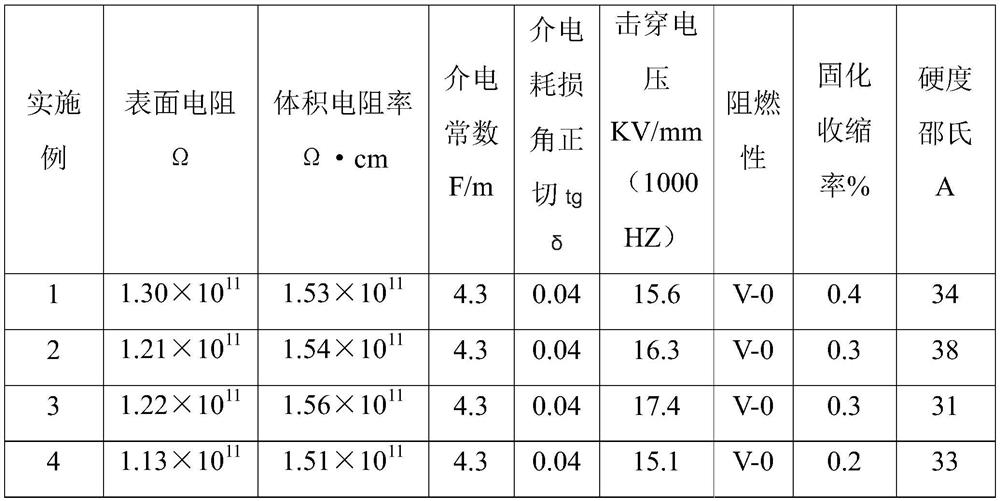

Examples

preparation example Construction

[0023] A preparation method of polyurethane potting glue, comprising the steps of:

[0024] S1. Preparation of component A: vacuum dehydrate polytetrahydrofuran ether diol and polyether polyol at 125°C-150°C, lower the temperature below 45°C, add flame retardant, flame retardant diluent and adhesion promoter, and pack with nitrogen gas , get A component;

[0025] S2. Preparation of component B: vacuum dehydrate the hydroxyl polyol at 125°C-150°C, cool down to 60-75°C, add antioxidant, then add toluene diisocyanate and catalyst and react at 85-90°C for 2-6 hours , carry out nitrogen protection during the reaction process, analyze NCO to the end point, lower the temperature, add plasticizer and stir evenly to obtain component B;

[0026] S3. Preparation of polyurethane potting compound: mixing component A in step S1 and component B in step S2 to obtain a polyurethane potting compound.

[0027] Further, the raw material composition and weight ratio of the A component are: polye...

Embodiment 1

[0037] A preparation method of polyurethane potting glue, comprising the steps of:

[0038] S1. Preparation of component A: vacuum dehydrate polytetrahydrofuran ether diol and polyether polyol at 125°C, lower the temperature below 45°C, add inorganic phosphate, phosphite and epoxy silane coupling agent, and pack with nitrogen gas. Get A component;

[0039] S2. Preparation of component B: dehydrate pentaerythritol under vacuum at 125°C, cool down to 60°C, add antioxidant, then add toluene diisocyanate and dibutyltin dilaurate, react at 85°C for 2 hours, and carry out nitrogen protection during the reaction process , analyze NCO to the end point, lower the temperature, add plasticizer and stir evenly to obtain component B;

[0040] S3. Preparation of polyurethane potting compound: mixing component A in step S1 and component B in step S2 to obtain a polyurethane potting compound.

Embodiment 2

[0042] A preparation method of polyurethane potting glue, comprising the steps of:

[0043] S1. Preparation of component A: vacuum dehydrate polytetrahydrofuran ether diol and polyether polyol at 130°C, lower the temperature below 45°C, add phosphorus-nitrogen mixed intumescent flame retardant, phosphite and mercapto-based silane coupling agent , packed with nitrogen gas to obtain component A;

[0044] S2. Preparation of component B: vacuum dehydrate pentaerythritol and dipentaerythritol at 130°C, cool down to 65°C, add antioxidant, then add toluene diisocyanate and dibutyltin dilaurate to react at 90°C for 4 hours, and the reaction process proceeds Nitrogen protection, analyze NCO to the end point, lower the temperature, add plasticizer and stir evenly to obtain component B;

[0045] S3. Preparation of polyurethane potting compound: mixing component A in step S1 and component B in step S2 to obtain a polyurethane potting compound.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com