Hole-blocking-preventing ultra-light sealing material for water seepage test of large-gap asphalt pavement

A technology for asphalt pavement and water seepage test, applied in the analysis of suspension and porous materials, analysis of materials, permeability/surface area analysis, etc. To achieve the effect of improving the sealing water effect, convenient for carrying out the test, and the storage time is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

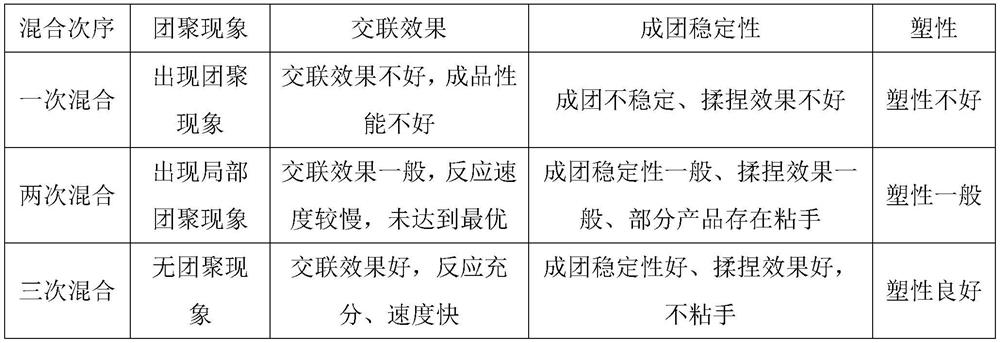

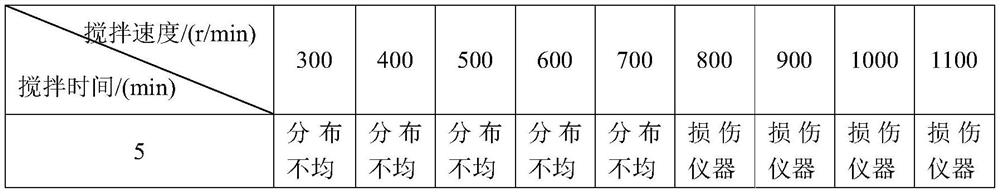

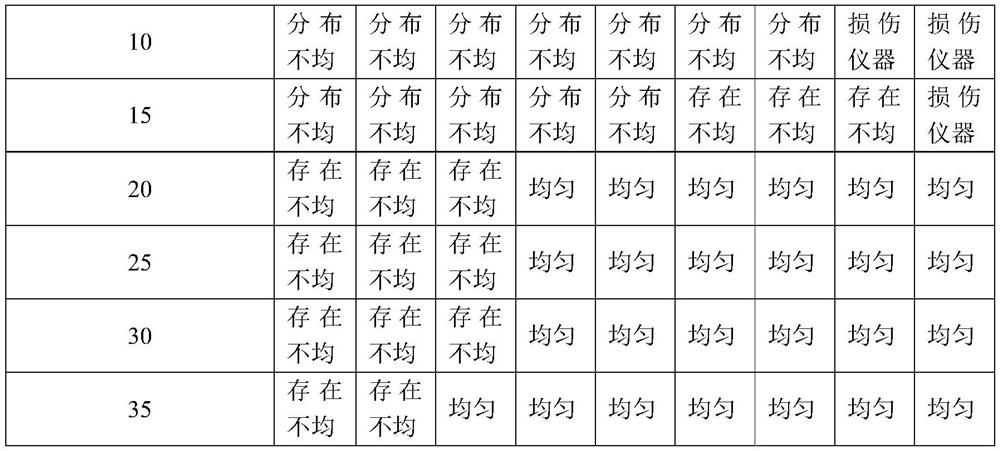

Method used

Image

Examples

Embodiment 1

[0039] 1. Formulation (weight ratio): 10 binder, 4 waterproof putty, 2 gels, 10 water, 10 parts of the filler, 0.85 dye, 1.6 dispensing agent, 15 wetting agent 0.4 parts of anti-mold agent; wherein the binder is a polyvinyl alcohol 0588 type, manufacturer: Shanghai Ziyi reagent factory, gel is 1,5-glutaraldehyde, manufacturers: Hubei Jinghong Biotechnology Co., Ltd. The filler is a hydrophobic gas phase silica HB-152, manufacturer: Hubei Huifuan Metaterial Co., Ltd. For polyether modified polydimethylsiloxane 351, manufacturer: Shanghai Ziyi reagent factory, wetting agent is propylene glycol and glycerol mixture, 1,2-propylene glycol, manufacturer is: Guangdong Yulong Industrial Co., Ltd., 1, 2 , 3-propalkanol, manufacturers: Guangdong Yulong Industrial Co., Ltd., anti-mildew is Causong ZB104, manufacturers: Shandong Wanhua Tianhe New Materials Co., Ltd.

[0040] 2, method method

[0041] (1) Removing the binder in the reactor by the weight of the recipe to be put into the reactor...

Embodiment 2

[0045] 1. Formulation (weight ratio): 9 binder, 3 waterproof putty, 2 gel, 52 water, 9 filler, 0.85 parts of the dye, 1.6 dispensing agent, 16 wetting agent 0.4 parts of anti-mold agent; wherein the binder is a polyvinyl alcohol 0588 type, manufacturer: Shanghai Ziyi reagent factory, gel is 1,5-glutaraldehyde, manufacturers: Hubei Jinghong Biotechnology Co., Ltd. The filler is a hydrophobic gas phase silica HB-152, manufacturer: Hubei Huifuan Metaterial Co., Ltd. For polyether modified polydimethylsiloxane 351, manufacturer: Shanghai Ziyi reagent factory, wetting agent is propylene glycol and glycerol mixture, 1,2-propylene glycol, manufacturer is: Guangdong Yulong Industrial Co., Ltd., 1, 2 , 3-propalkanol, manufacturers: Guangdong Yulong Industrial Co., Ltd., anti-mildew is Causong ZB104, manufacturers: Shandong Wanhua Tianhe New Materials Co., Ltd.

[0046] 2, method method

[0047] (1) Removing the binder in the reactor by the weight of the recipe to be put into the reactor, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com