Preparation method of fluorescent-powder-free recoverable epoxy adhesive for white-light LED (light-emitting diode) packaging

An epoxy adhesive, LED packaging technology, applied in the direction of epoxy resin glue, adhesives, adhesive additives, etc., can solve the problems of fluorescence quenching, low quality, high flexibility, etc., achieve mild reaction conditions, and the preparation method Simple, excellent product performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

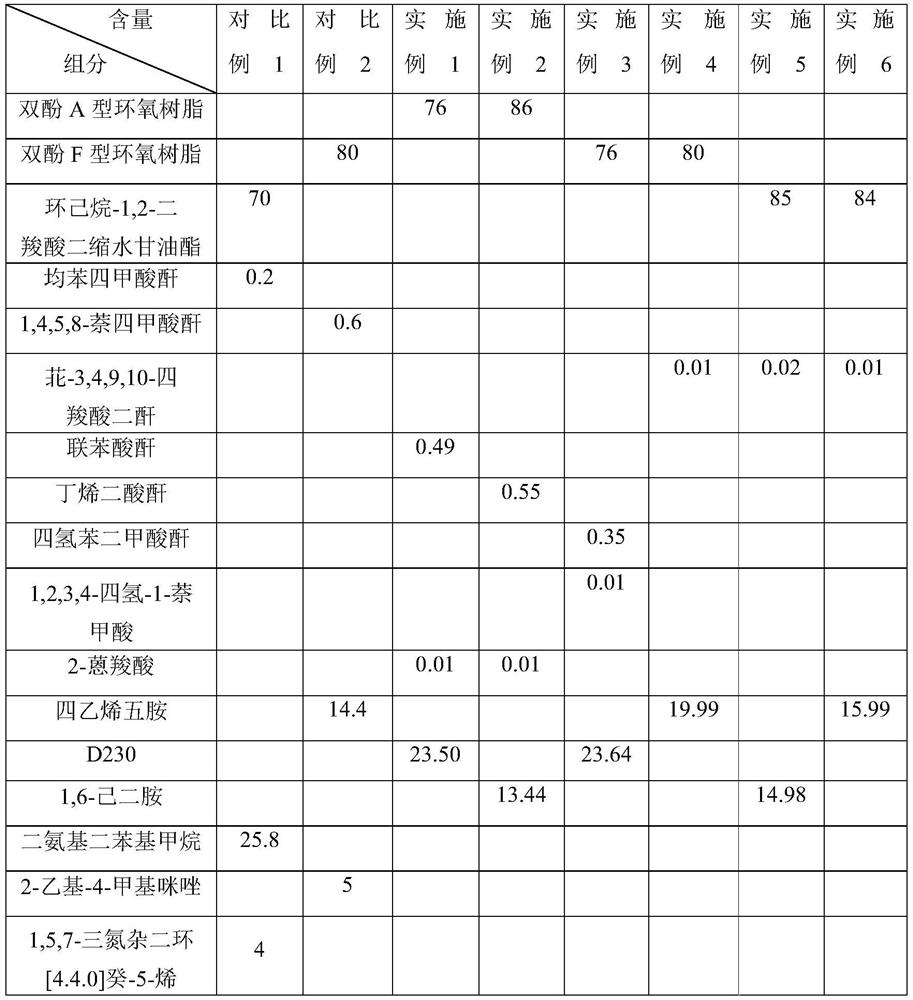

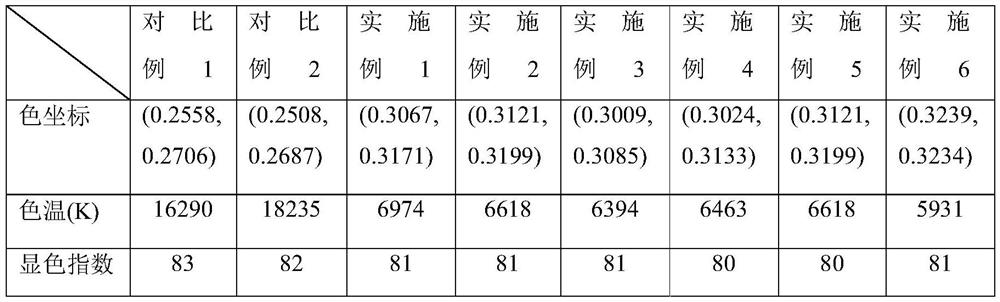

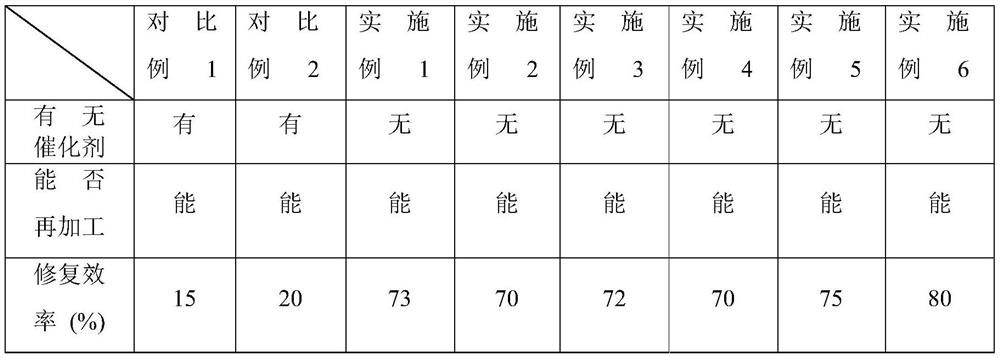

Examples

Embodiment 1

[0023] Example 1: At room temperature, formulate the components according to Example 1 in Table 1, mix bisphenol A epoxy resin with biphenyl anhydride and 2-anthracene carboxylic acid, and then grind it with a three-roll machine to become fine and uniform The mixture obtained was transferred to a three-necked flask, stirred and condensed in an oil bath at 170° C. for 2 h. After the liquid was taken out and refluxed, it was cooled to 25°C, polyetheramine D230 was added, and stirred under vacuum at 25°C to remove air bubbles, and the fluorescent powder-free recyclable epoxy adhesive of the embodiment of the present invention was prepared.

Embodiment 2

[0024] Embodiment 2: At normal temperature, formulate each component according to embodiment 2 in table 1, bisphenol A type epoxy resin is mixed with butenedioic anhydride and 2-anthracene carboxylic acid, become fine and smooth after three-roll machine grinding homogeneous mixture, the resulting fine and homogeneous mixture was transferred to a three-necked flask, stirred and condensed in an oil bath at 200°C for 1 h. After the reflux was taken out, the liquid was cooled to 40°C, 1,6-hexamethylenediamine was added, and stirred in a vacuum at 40°C to remove air bubbles, and the fluorescent powder-free recyclable epoxy adhesive of the embodiment of the present invention was prepared.

Embodiment 3

[0025] Embodiment 3: At normal temperature, formulate each component according to embodiment 3 in table 1, bisphenol F type epoxy resin and tetrahydrophthalic anhydride and 1,2,3,4-tetrahydro-1-naphthalene The formic acid was mixed, and after being ground by a three-roll machine, a fine and uniform mixture was obtained. The obtained fine and uniform mixture was transferred to a three-necked flask, stirred, condensed and refluxed in an oil bath at 160°C for 3 hours. After the reflux was taken out, the liquid was cooled to 30°C, polyetheramine D230 was added, and stirred under vacuum at 25°C to remove air bubbles, and the phosphor-free recyclable epoxy adhesive of the embodiment of the present invention was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com