Flywheel rotor and preparation method thereof

A flywheel rotor and rotor technology, applied in the field of energy storage systems, can solve the problem that steel materials cannot take into account the cost and hardenability, etc., and achieve the effects of being conducive to mass production, high hardenability, and consistent core structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

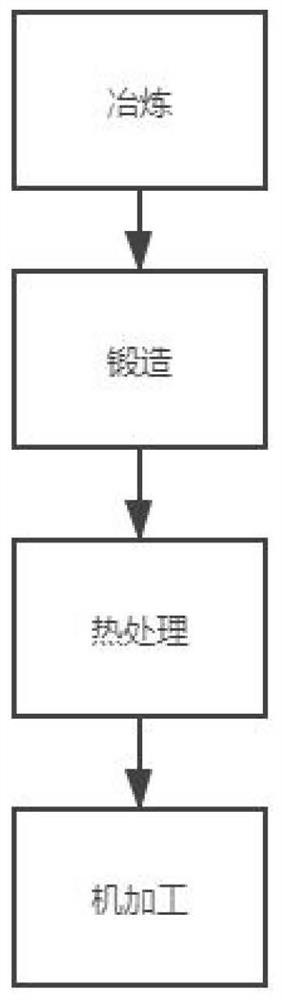

Method used

Image

Examples

Embodiment 1

[0059] Electric arc furnace smelting + extra-furnace refining + electroslag remelting is used to prepare energy storage flywheel rotor steel. In terms of mass content, its chemical composition is: C is 0.32%, Si is 1.55%, Mn is 3.10%, and Cr is 1.0%. , Mo is 0.25%, Ni is 0.25%, V is 0.08%, B is 0.0005%, and the balance is Fe and unavoidable impurities. The homogenization temperature of the steel ingot is 1200°C, and the holding time is 8 hours. The ingot heating temperature is 1200°C, the initial forging temperature is 1150°C, the final forging temperature is 880°C, and the forging ratio is 8. Normalize at 900°C, keep warm for 5 hours, and cool in air. Quenching temperature 850°C, holding time 5 hours, air cooling. Tempering temperature 250°C, holding time 8 hours, air cooling.

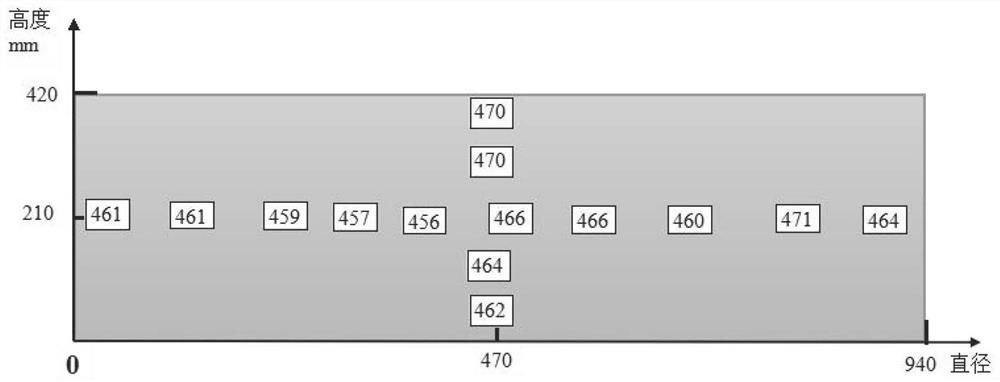

[0060] The outer diameter of the flywheel rotor is 940mm, and the height is 420mm. Samples are taken at the edge and center of the rotor.

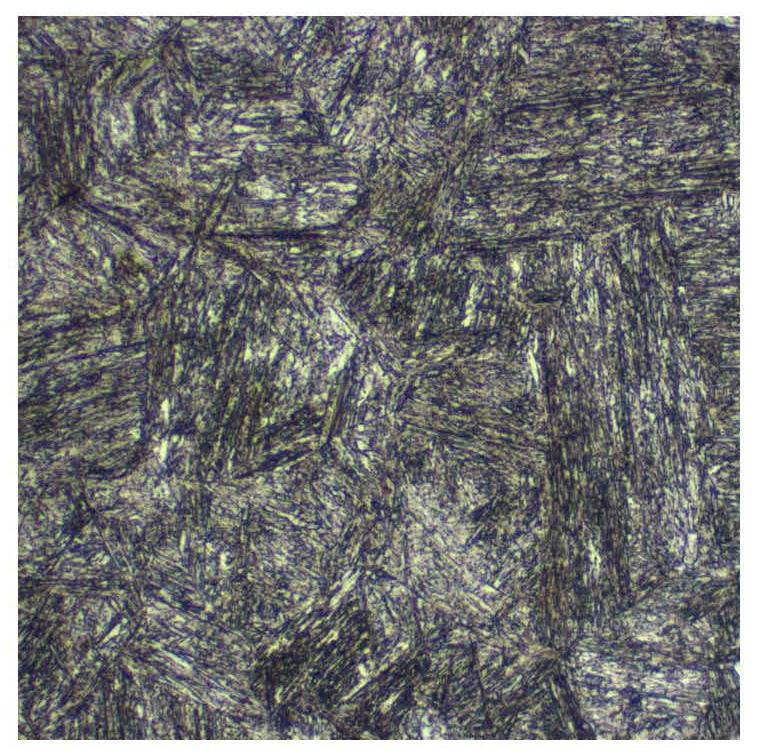

[0061] The actual rotor of Example 1 was dissected, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com