Nickel oxide electrochromic composite film and preparation method and application thereof

An electrochromic and composite film technology, applied in ion implantation plating, coating, instruments, etc., can solve the problems that it is difficult to exceed 150°C, PET is not suitable, and the temperature resistance of PET materials is not high, so as to suppress color attenuation , Provide stability, high charge capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Another aspect of the aspect of the present invention further provides a method for preparing the above-described electrochromic composite nickel oxide film, comprising:

[0045] Providing a substrate provided with a transparent conductive layer;

[0046] By magnetron sputtering, the target is a target of nickel oxide deposited on the surface of the transparent conductive layer forming the nickel oxide layer;

[0047] And, by magnetron sputtering, the target to zinc tin oxide as a target, an amorphous zinc tin oxide is deposited a buffer layer on a surface of the nickel oxide layer, thereby obtaining a nickel oxide electrochromic composite film.

[0048] In some more specific embodiments, the target comprising a pure nickel oxide or nickel oxide target co-doped nickel oxide target, and is not limited thereto.

[0049] Further, the co-doped nickel oxide target comprising Li, Si target co-doped nickel oxide or Sn, Ta, Nb and W, respectively, co-doped nickel oxide target, and ...

Embodiment 1

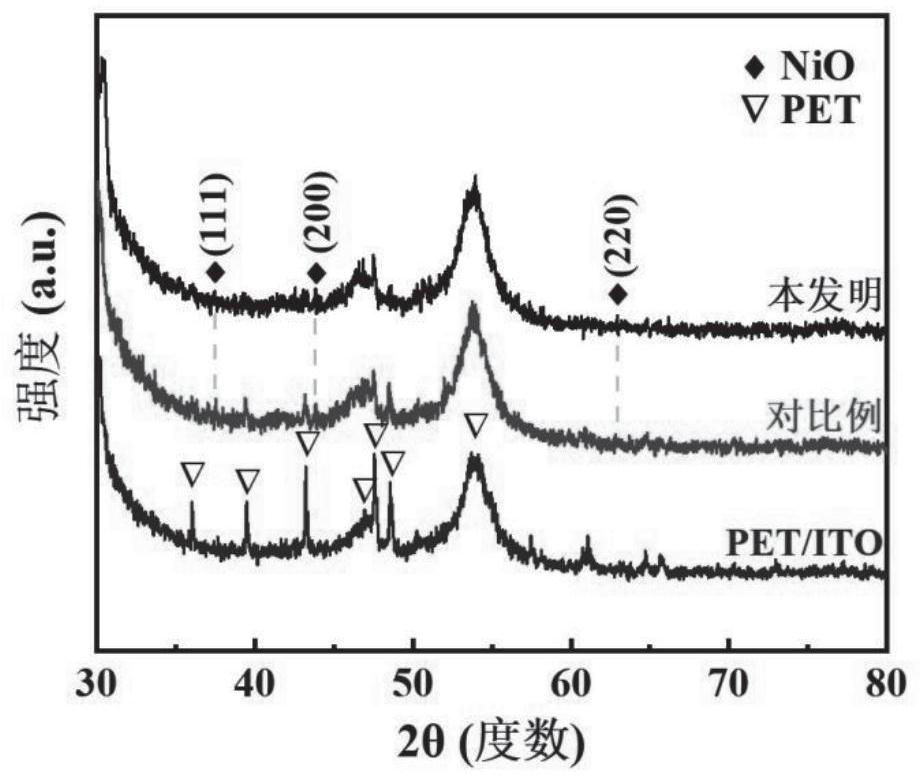

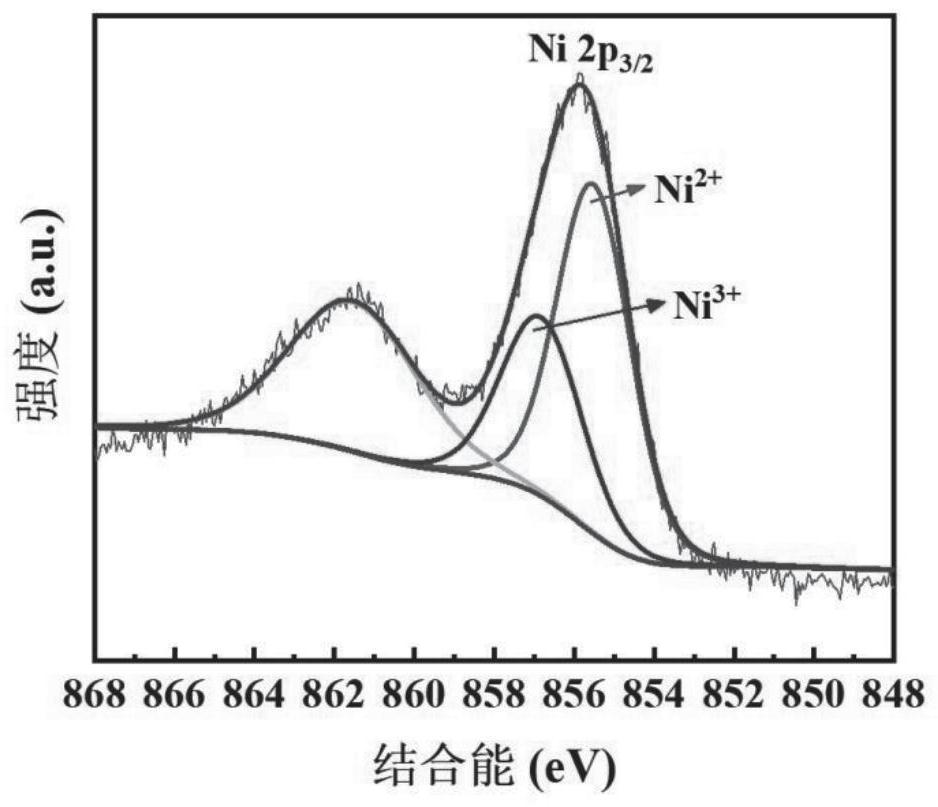

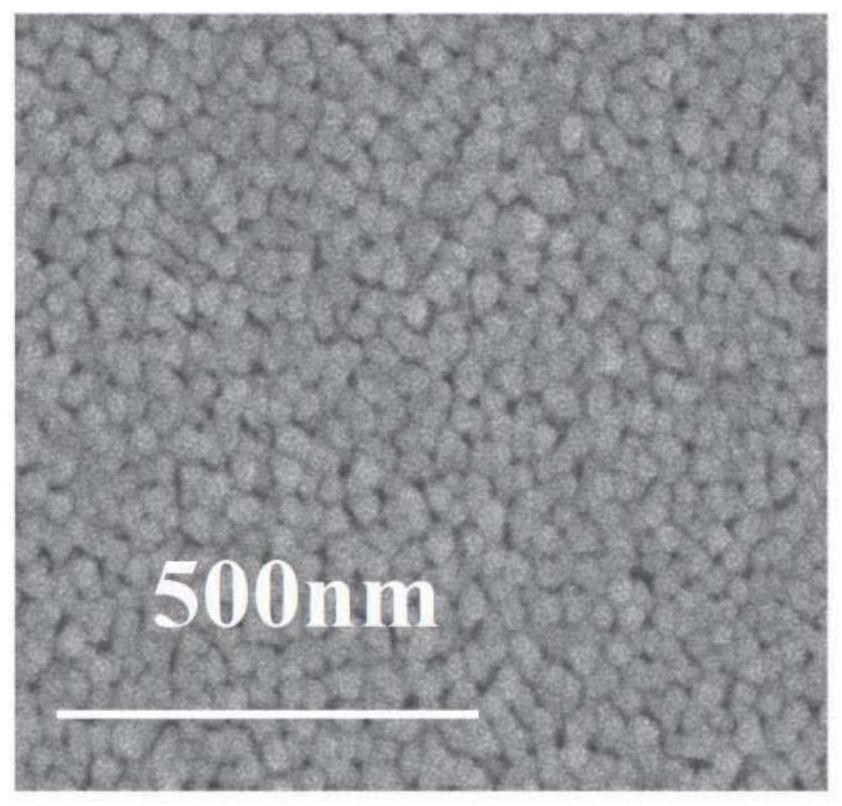

[0072] (1) Magnetron sputter deposition of Ni-oxide film

[0073] The Si and Li co-doped nickel oxide target placed in the magnetron sputtering device, depositing a thin film of nickel oxide nanorods on a conductive layer covering the ITO transparent PET substrate. During sputtering parameters are as follows: sputtering an intermediate frequency sputtering, the working gas is pure argon; the substrate temperature was 80 deg.] C; degree of vacuum of 5 × 10 -2 PA; sputtering gas pressure is 2.0 Pa; sputtering power density was 4.5W / cm 2 ; Thickness of the nickel oxide film is 140nm;

[0074] (2) by magnetron sputtering zinc tin oxide film deposited

[0075] The zinc tin oxide target placed magnetron sputtering apparatus, in step (1) zinc tin oxide film is deposited on the nickel oxide film is deposited, during sputtering main parameters are as follows: sputtering an intermediate frequency sputtering, working gas is pure argon; the substrate temperature was 80 deg.] C; degree of va...

Embodiment 2

[0089] (1) Magnetron sputter deposition of Ni-oxide film

[0090] Pure nickel oxide target placed in the magnetron sputtering device, depositing a thin film of nickel oxide nanorods on a conductive layer covering the ITO transparent PET substrate. During sputtering parameters are as follows: RF sputtering, sputtering or medium frequency sputtering, the working gas is pure argon; the substrate temperature was 25 deg.] C; degree of vacuum of 0.1 × 10 -2 PA; sputtering gas pressure is 0.4 Pa; sputtering power density was 2.0W / cm 2 ; Thickness of the nickel oxide film is 80nm;

[0091] (2) by magnetron sputtering zinc tin oxide film deposited

[0092] The zinc tin oxide target placed magnetron sputtering apparatus, in step (a) depositing a nickel oxide film is deposited on the zinc tin oxide film, sputtering the main parameters are as follows: RF sputtering, sputtering or IF sputtering, the working gas is pure argon; the substrate temperature was 25 deg.] C; degree of vacuum of 0.1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com