Establishment method and application of comprehensive evaluation model of solid fuel for sintering

A solid fuel, comprehensive evaluation technology, applied in the metallurgical field, can solve the problems of not considering the pollutant discharge and production cost of sintered fuel, and not suitable for the use of enterprise procurement departments, and achieve the effect of easy evaluation and convenient calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

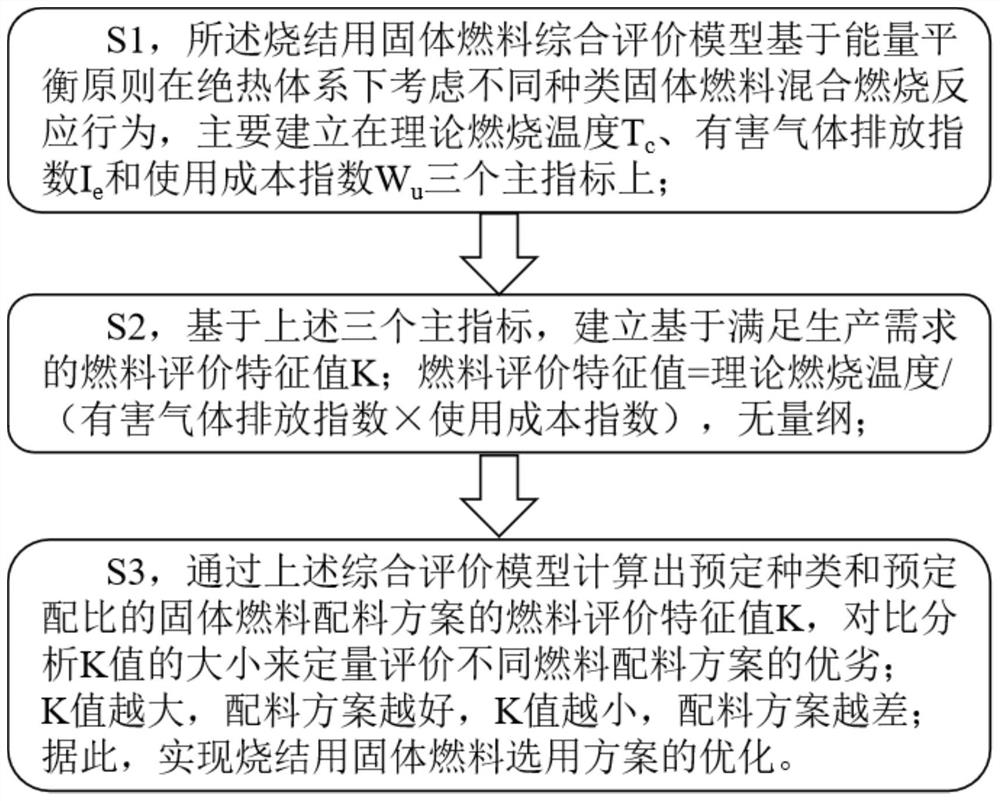

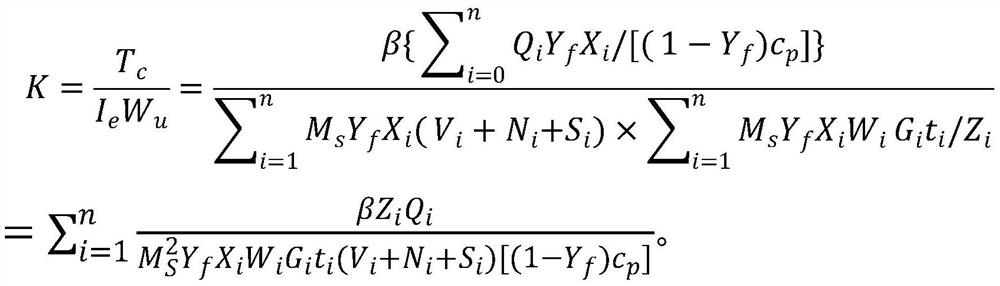

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1 of the present invention provides a method for establishing a comprehensive evaluation model of solid fuel for sintering, which is used for evaluation and calculation of solid fuel for sintering, specifically as follows:

[0077] 1. Fuel industry analysis is tested according to the national standard CB212-91, and the air-dry basis volatile content of coal types is obtained.

[0078] 2. Fuel element analysis is tested according to the national standard GB 476-91, and the content of N and S on an air-dry basis is obtained.

[0079] 3. The calorific value of the fuel is tested according to the national standard GB213-87, and the low calorific value is calculated.

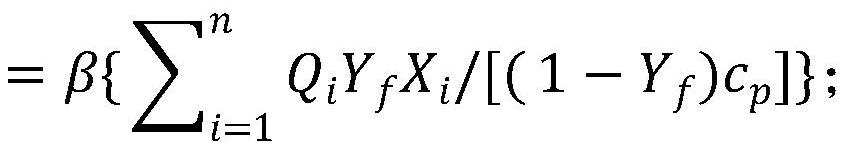

[0080] 4. Under the adiabatic system, the theoretical combustion temperature of the fuel in the sinter mixture is calculated as follows:

[0081]

[0082] 5. The harmful gas emission index of fuel combustion is calculated as follows:

[0083]

[0084] 6. The grindability index of the fuel is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com