A controllable pressure manipulator end effector with polishing manipulator

A technology of end effector and public rotation, which is applied in the direction of grinding/polishing equipment, abrasive belt grinder, grinding machine tool parts, etc., can solve the problems such as the limitation of surface curvature radius, and achieve the prevention of interference phenomenon, large bearing capacity, and realization of The effect of elastic recoil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

[0051] The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

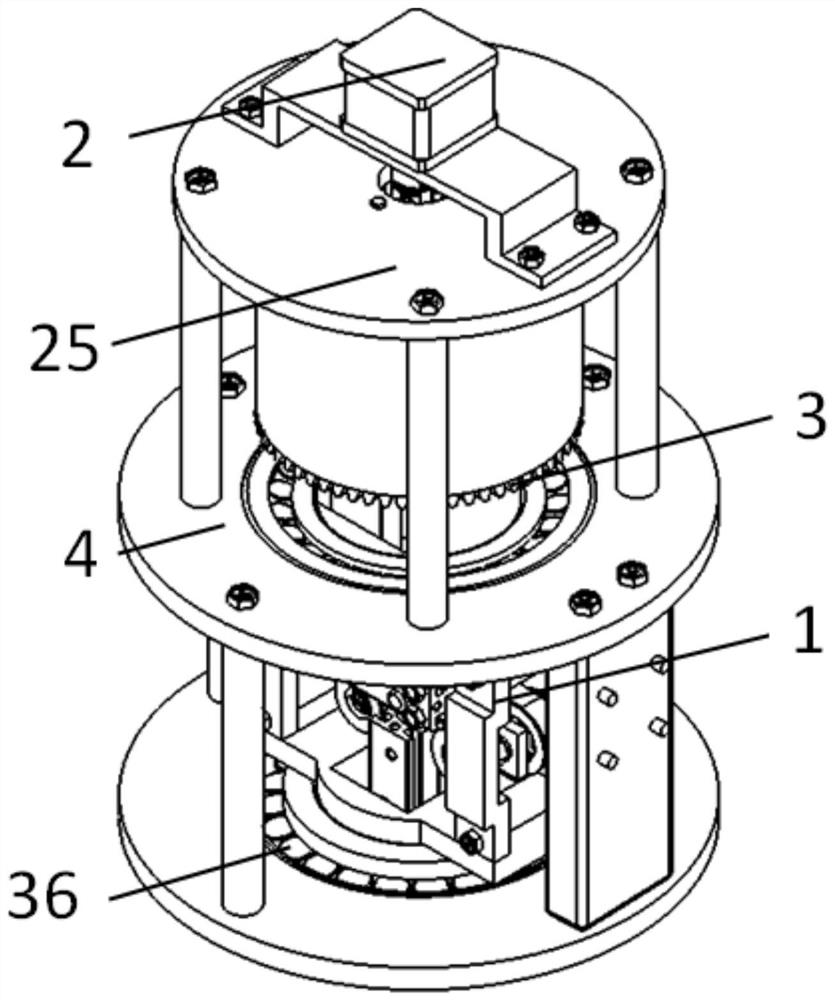

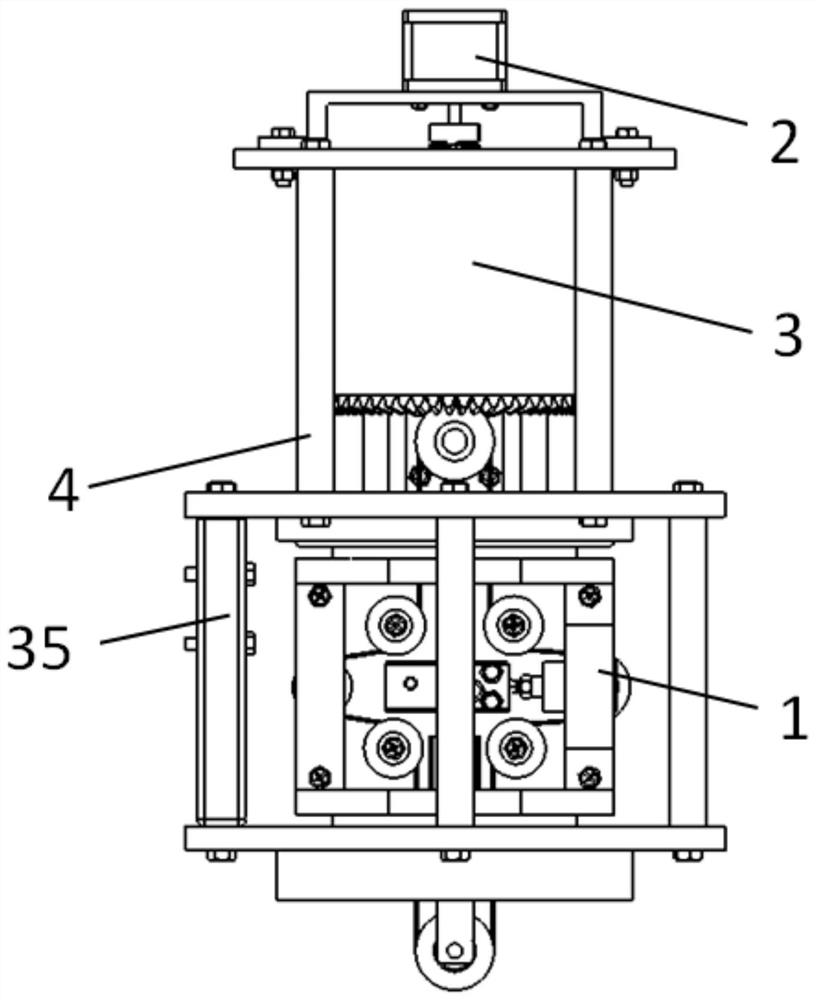

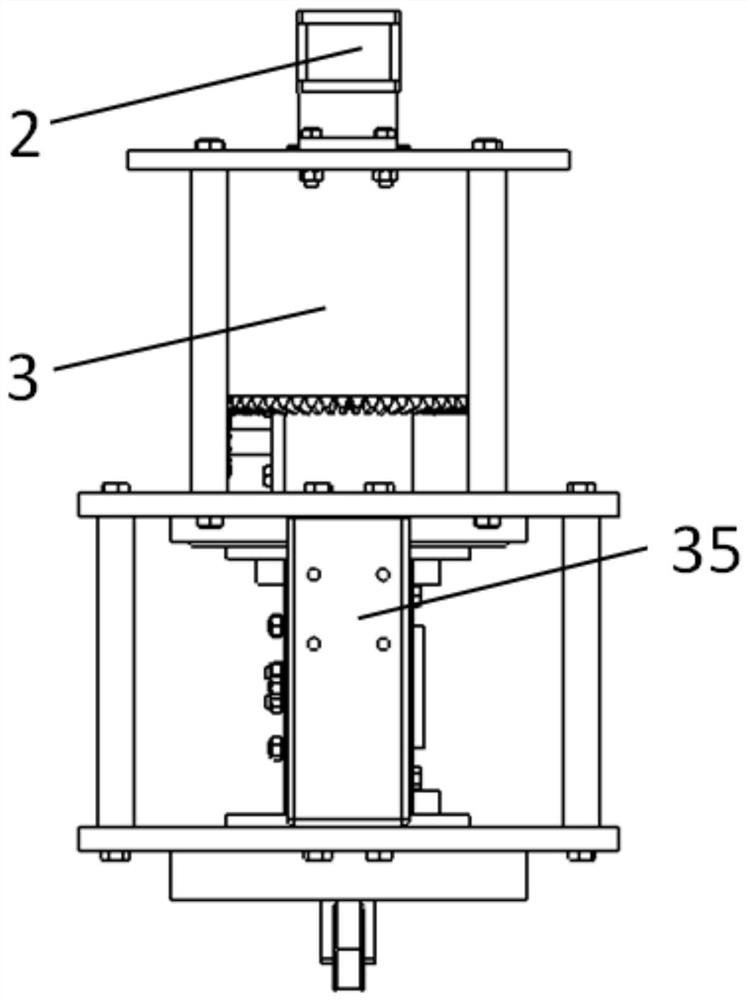

[0052] like Figure 1-Figure 25 As shown in the figure, a controllable pressure manipulator belt polishing manipulator end effector includes a belt polishing assembly 1, a motor drive assembly 2, a pneumatic rotation assembly 3, a supporting assembly 4, a tensioning assembly 6, and a polishing belt 11. and a number of adjustable guide idlers 9, the upper and lower ends of the belt polishing assembly 1 are respectively supported and installed on the support assembly 4 through a tapered roller bearing 36, and the pneumatic rotation assembly 3 is fixed on the top of the support assembly 4, so The pneumatic rotating assembly 3 is arranged above the belt poli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com