Preparation method of filter element capable of removing heavy metals

A heavy metal and filter element technology, which is applied in the field of preparation of water purification filter element materials, can solve the problems of filter element performance stability, large amount of organic waste liquid and waste gas, environmental pollution, etc., and achieve efficient and stable removal effect, heavy metal adsorption capacity The effect of large and expanding the range of material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

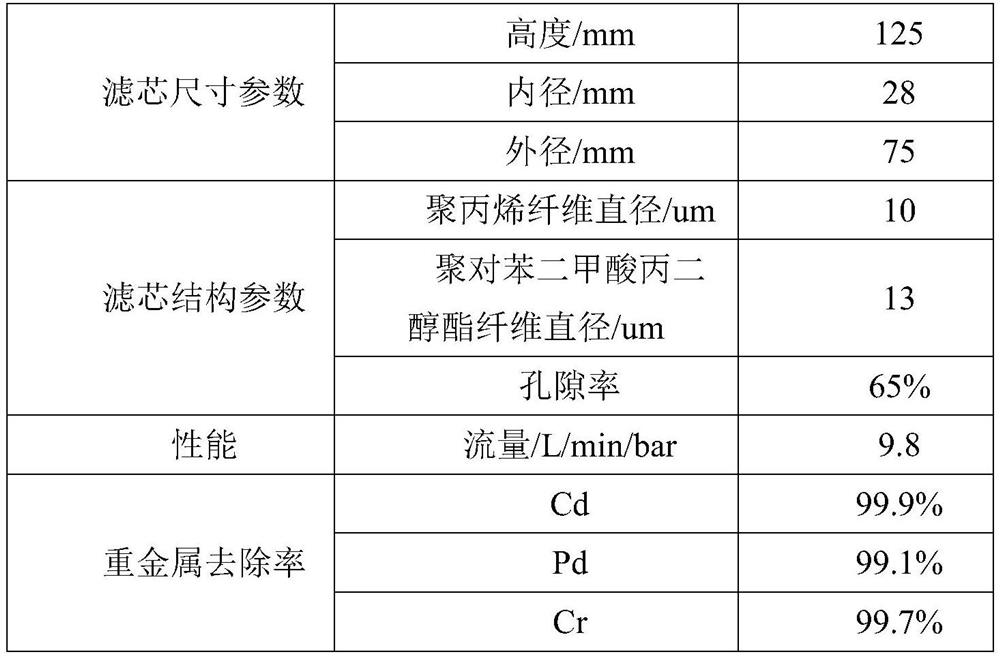

[0019] Embodiment 1, at first utilize melt-blowing equipment to prepare the inner layer is the polypropylene layer, the outer layer is the annular cylinder filter element of polytrimethylene terephthalate, and the annular cylinder filter element is axially hollow; Above-mentioned filter element puts concentration is 10 %, the temperature is 90 DEG C of chitosan aqueous solution, after reacting for 24 hours, take it out; wash the reacted filter core with 40 DEG C pure water for 1 hour; put the rinsed filter core into a 60 DEG C oven and dry for 48 hours to obtain the final filter core.

[0020]

Embodiment 2

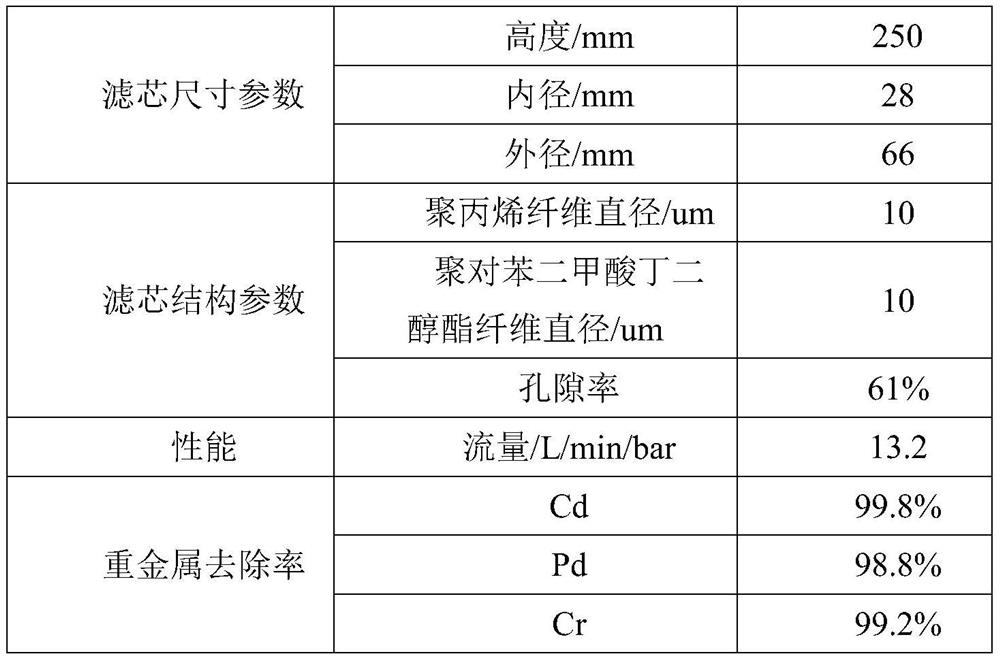

[0021] Embodiment 2, at first utilize the melt-blown equipment to prepare the inner layer is the polypropylene layer, and the outer layer is polybutylene terephthalate melt-blown circular cylinder filter element; The above-mentioned filter element is put into concentration and is 5%, temperature After reacting for 8 hours in an aqueous solution of ethylenediaminetetraacetic acid at 70°C, take it out; wash the reacted filter element with pure water at 60°C for 10 hours; put the rinsed filter element in an oven at 60°C for 12 hours to obtain the final filter element.

[0022]

Embodiment 3

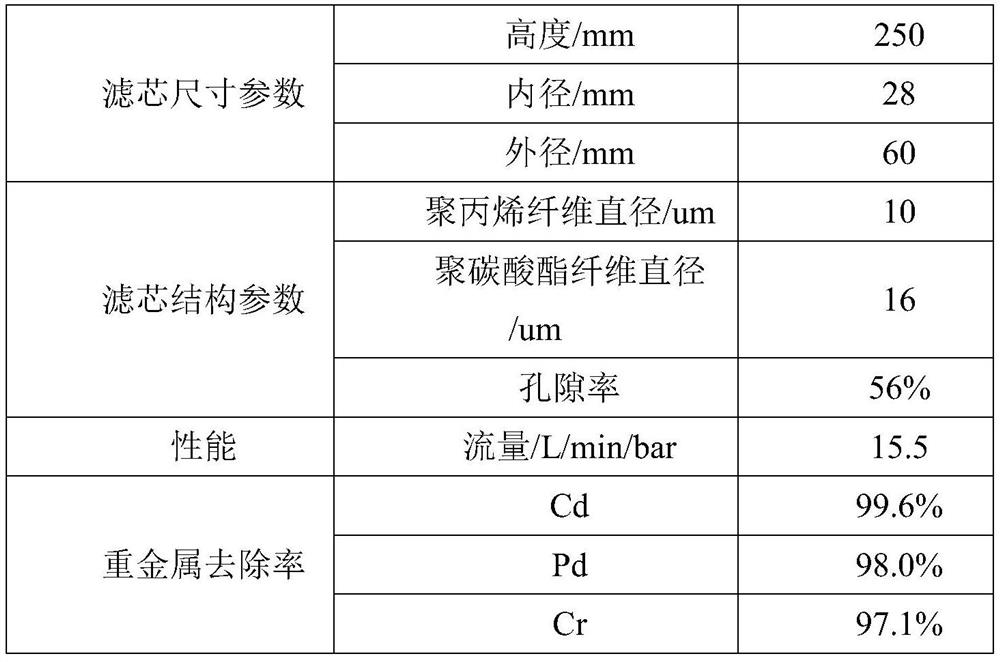

[0023] Embodiment 3, at first utilize the melt-blown equipment to prepare the toroidal cylindrical filter element of polycarbonate; Put the above-mentioned filter element into the aqueous solution of nitrilotriacetic acid with a concentration of 10% and a temperature of 80° C. After reacting for 12 hours, take it out; The final filter element was washed with 60°C pure water for 12 hours; the rinsed filter element was put into an oven at 60°C for 12 hours to obtain the final filter element.

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com