Preparation method of semaglutide full-protection peptide resin and preparation method of semaglutide

A fully protected, peptide resin technology, applied in the field of peptide synthesis, can solve problems such as increased production costs, difficulty in obtaining high-quality crude products, and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

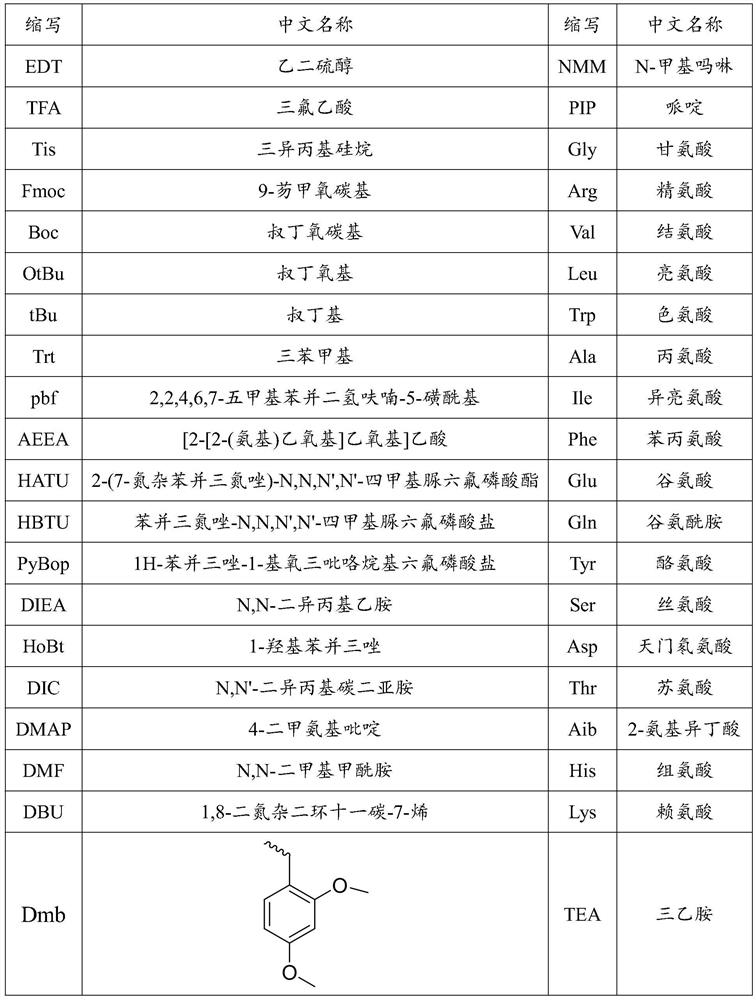

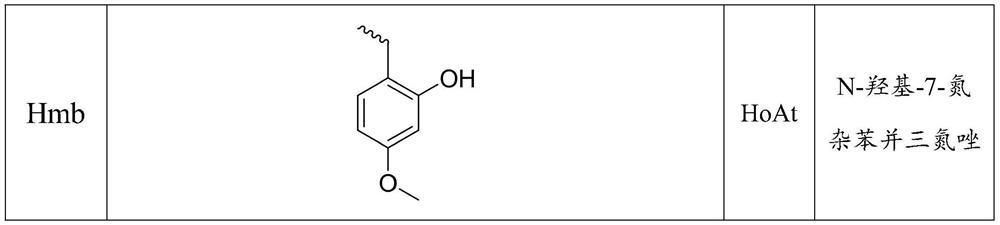

[0021] The invention provides a preparation method of semaglutide fully protected peptide resin, comprising the following steps: according to the sequence of semaglutide, taking Fmoc-Gly 31 -resin, sequentially coupled with the amino acid shown in formula I or the dipeptide fragment shown in formula II and the raw material that provides the remaining amino acids in the semaglutide sequence to obtain a semaglutide fully protected peptide resin, the formula I is Fmoc-N(R)-AA 1 -OH, the formula II is Fmoc-AA 2 -N(R)-AA 1 -OH, R in the formula I and II is Dmb or Hmb, AA in the formula I and II 1 for Gly 29、Leu 26 、Ala 24 、Ala 19 、Ala 18 、Gly 16 、Leu 14 One or more of the AA 2 is Arg(Pbf) 28 、Trp(Boc) 25 、Ile 23 、Ala 18 、Gln(Trt) 17 、Glu(OtBu) 15 、Tyr(tBu) 13 In one or more of the above, the raw material that provides the remaining amino acids in the semaglutide sequence includes amino acids and / or peptide fragments, and the amino acids and / or peptide fragments hav...

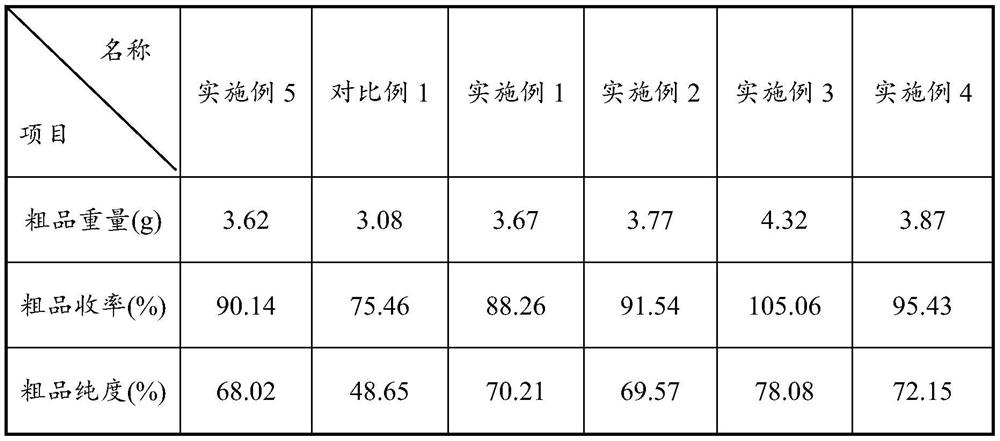

Embodiment 1

[0082] Weigh 17.24g of Wang Resin with a degree of substitution of 0.58mmol / g, add it to the synthesis reactor, add DMF to swell for 30min, and remove the DMF solution; weigh Fmoc-Gly 31 Add 4.46g of -OH and 2.05g of HoBt into the synthesis reactor, dissolve with DMF, blow nitrogen, add DIC2.310ml, react for 10min, weigh 0.366g of DMAP and add to the above reaction mixture, continue the reaction for 3h, pump out the reaction mixture solution, washed the resin 5 times with DMF, capped with 200ml acetic anhydride / NMM / DMF for 3h, washed 2 times with DMF, 2 times with MeOH, 2 times with DCM, 2 times with MeOH, dried in vacuum to constant weight, and obtained Fmoc -Gly 31 - WangResin 31.82g, the measured substitution degree is 0.31mmol / g.

[0083] Weigh Fmoc-Gly with a substitution degree of 0.31mmol / g 31 -Wang Resin 3.26g, added to the synthesis reactor, swollen with DMF for 60min, pumped out the DMF solution, added 20% PIP / DMF solution to remove Fmoc, washed the resin 5 times w...

Embodiment 2

[0090] Weigh 17.24g of Wang Resin with a degree of substitution of 0.58mmol / g, add it to the synthesis reactor, add DMF to swell for 30min, and remove the DMF solution; weigh Fmoc-Gly 31 Add 4.46g of -OH and 2.05g of HoBt into the synthesis reactor, dissolve with DMF, blow nitrogen, add 2.310ml of DIC, react for 10min, weigh 0.366g of DMAP and add to the above reaction mixture, continue the reaction for 3h, pump out the reaction mixture solution, washed the resin 5 times with DMF, capped with 200ml acetic anhydride / NMM / DMF for 3h, washed 2 times with DMF, 2 times with MeOH, 2 times with DCM, 2 times with MeOH, dried in vacuum to constant weight, and obtained Fmoc -Gly 31 - WangResin 31.82g, the measured substitution degree is 0.31mmol / g.

[0091] Weigh Fmoc-Gly with a substitution degree of 0.31mmol / g 31 -Wang Resin 3.23g, added to the synthesis reactor, swelled with DMF for 60min, pumped out the DMF solution, added 20% PIP / DMF solution to remove Fmoc, washed the resin 5 tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com