Preparation method of benzyl isothiocyanate compound

A technology of benzyl isothiocyanate and compound, applied in the field of preparation of benzyl isothiocyanate compounds, can solve problems such as complicated steps, severe reaction conditions, etc., and achieves simple operation, easily available raw materials, and mild reaction conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of benzyl isothiocyanate compound 3a

[0022]

[0023] Add 4-ethylanisole 1a (0.3mmol, 41mg), trimethylsilyl isothiocyanate 2 (0.6mmol, 79mg), tetrabutyl ammonium hexafluorophosphonate (0.6mmol, 232mg) and dichloroethane and hexafluoroisopropanol (3:1, 6mL). Graphite felt (1cm x 1.5cm x 1cm) was used as the anode and a nickel sheet (1cm x 1cm x 0.1mm) was used as the cathode. The reaction mixture was stirred at room temperature for 6 hours at a constant current of 7 mA. After the reaction was complete, the solvent was removed using a rotary evaporator. The product 3a was obtained by silica gel column chromatography using petroleum ether and ethyl acetate (20:1) as eluent with a yield of 72%.

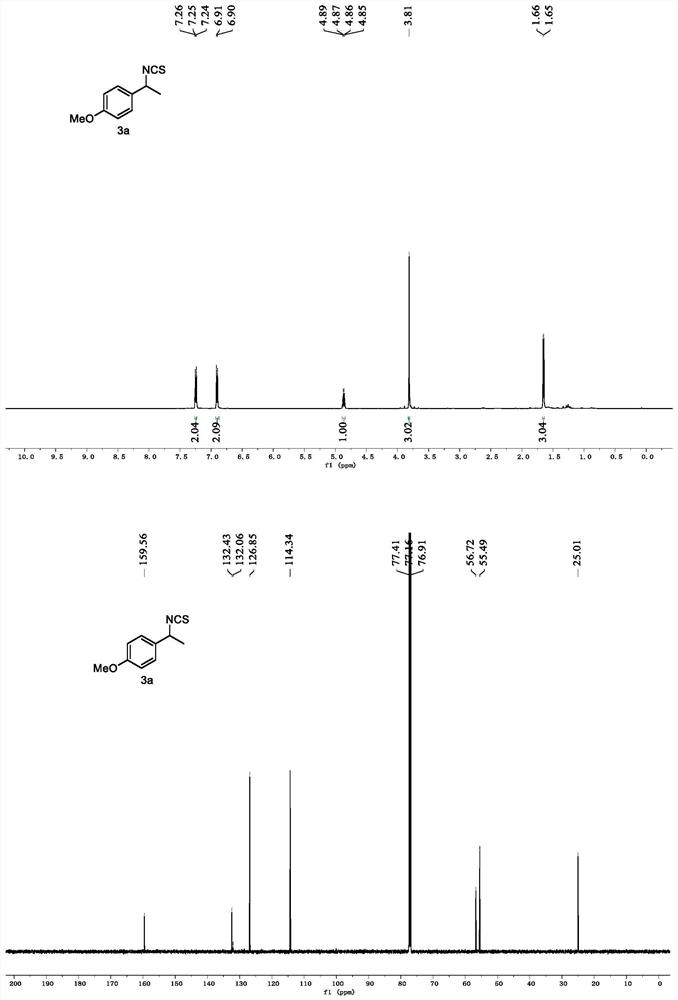

[0024] Spectral analysis data 3a:

[0025] 1 H NMR (500MHz, CDCl 3 )δ7.25(d, J=8.5Hz, 2H), 6.90(d, J=8.7Hz, 2H), 4.87(q, J=6.8Hz, 1H), 3.81(s, 3H), 1.65(d, J=6.8Hz,3H).

[0026] 13 C NMR (125MHz, CDCl 3 )δ159.6, 132.4, 132.1, 126.9, 114.3, 56.7, 55.5, 25.0...

Embodiment 2

[0028]

[0029] Add p-bromoethylbenzene 1b (0.3mmol, 56mg), trimethylsilyl isothiocyanate 2 (0.6mmol, 79mg), tetrabutylammonium perchlorate (0.6mmol, 205mg) and di Ethyl chloride and hexafluoroisopropanol (3:1, 6mL). Graphite felt (1cm x 1.5cm x 1cm) was used as the anode and a nickel sheet (1cm x 1cm x 0.1mm) was used as the cathode. The reaction mixture was stirred at room temperature for 6 hours at a constant current of 7 mA. After the reaction was complete, the solvent was removed using a rotary evaporator. The product 3b was obtained by silica gel column chromatography using petroleum ether and ethyl acetate (40:1) as eluent with a yield of 62%.

[0030] Spectrum analysis data 3b:

[0031] 1 H NMR (500MHz, CDCl 3 )δ7.51(d, J=8.5Hz, 2H), 7.20(d, J=8.5Hz, 2H), 4.88(q, J=6.8Hz, 1H), 1.65(d, J=6.8Hz, 3H) .

[0032] 13 C NMR (125MHz, CDCl 3 )δ139.3, 133.5, 132.2, 127.3, 122.2, 56.6, 25.0.

Embodiment 3

[0034] Replace 1b in Example 2 with 1c, and other conditions are the same as Example 2. The experimental results are shown in Table 1.

[0035]

[0036] Spectrum analysis data 3c:

[0037] 1 H NMR (500MHz, CDCl 3 )δ7.35(d, J=8.4Hz, 2H), 7.26(d, J=8.5Hz, 2H), 4.90(q, J=6.8Hz, 1H), 1.65(d, J=6.8Hz, 3H) .

[0038] 13 C NMR (125MHz, CDCl 3 )δ138.8, 134.2, 133.4, 129.2, 127.0, 56.6, 25.1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com