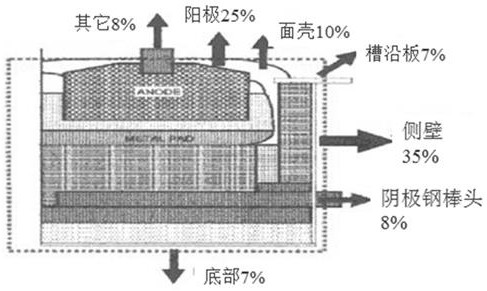

Method for external heat preservation, energy conservation and consumption reduction of furnace bottom of aluminium electrolysis cell

An aluminum electrolytic cell and the technology of the electrolytic cell are applied in the field of external heat preservation and energy saving and consumption reduction of the furnace bottom of the aluminum electrolytic cell to achieve the effect of saving the cost of thermal insulation materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

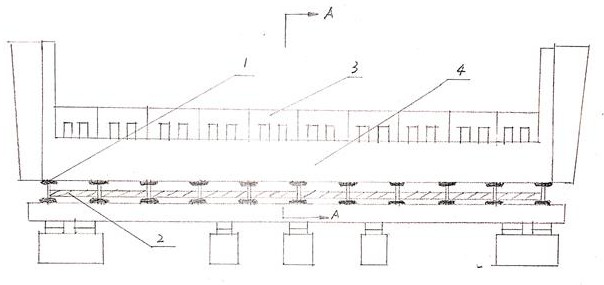

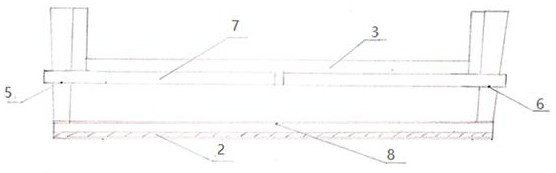

[0028] In the existing equipment, the bottom of the aluminum electrolytic cell is provided with a bottom I-beam 1, and the aluminum electrolytic cell is provided with a cathode carbon block group 3, a cathode lining refractory insulation layer 4 and a cathode steel rod 7. The innovation of the present invention is to provide a A method for external heat preservation and energy saving and consumption reduction of an aluminum electrolytic cell furnace bottom, comprising the following steps:

[0029] S1. Add a thermal insulation material layer 2 outside the bottom of the electrolytic cell, and the thermal insulation material layer 2 is a calcium silicate board or a ceramic fiber board;

[0030] S2. The thickness of the furnace side of the electrolytic cell is 10~20cm, the length of the extension leg (excluding the artificial extension leg) is 5~18cm, and the voltage drop of the bottom of the aluminum electrolytic cell is 180~390mV;

[0031] S3. A temperature measuring probe is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com