Molten salt electrolytic refining method and separation method of cathode precipitates thereof

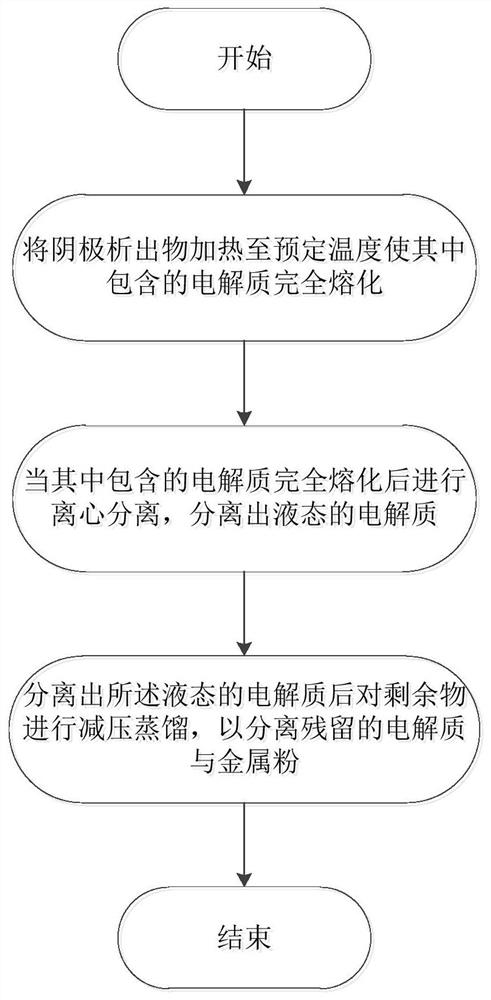

A separation method, molten salt electrolysis technology, applied in the separation of molten electrolytic refining cathode precipitates, molten salt electrolytic refining field, can solve the problems of difficult recovery and reuse of electrolyte, low process economy, poor separation effect, etc., to achieve convenient condensation Recycling, high separation efficiency and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 15kg of electrolytic titanium cathode precipitate, wherein the electrolyte is NaCl-KCl-TiCl n (2≤n≤3), the electrolyte content is 85wt%, the electrolytic titanium cathode precipitate is heated to 850 ° C, after the electrolyte contained therein is completely melted, the electrolytic titanium cathode precipitate is put into a centrifuge for centrifugation, and the centrifuge The rotation speed of the separation is 5000r / min. After separation for 20 minutes, the molten liquid electrolyte is drained, and the liquid electrolyte is recovered after condensation and crystallization to obtain 11.9kg of solid electrolyte. After calculation, the separation rate of the liquid electrolyte after centrifugation is 93.3%. The residue after centrifugal separation of most of the electrolytes was distilled under reduced pressure, the distillation temperature was 1000°C, the distillation pressure was 1Pa, and the distillation time was 2h to obtain 2.2kg of titanium powder and 0.85kg of ...

Embodiment 2

[0039] Take 15kg of electrolytic titanium cathode precipitate, wherein the electrolyte is LiCl-KCl-TiCl n (2≤n≤3), the electrolyte content is 55.1wt%, the electrolytic titanium cathode precipitate is heated to 400 ° C, after the electrolyte contained therein is completely melted, the electrolytic titanium cathode precipitate is put into a centrifuge for centrifugation, centrifuged The separation speed of the machine is 30000r / min. After separation for 40 minutes, the molten liquid electrolyte is drained, and the liquid electrolyte is recovered after condensation and crystallization to obtain 7.9kg of solid electrolyte. After calculation, the separation rate of liquid electrolyte after centrifugation is 95.6%. ; After centrifuging most of the electrolyte, the residue is subjected to vacuum distillation at a distillation temperature of 750°C and a distillation pressure of 2×10 -1 Pa, distillation time 3h, 6.7kg of titanium powder and 0.35kg of solid electrolyte were obtained. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com