Preparation method of methyl 3-methoxyacrylate

A technology of methyl methoxyacrylate and methyl dimethoxypropionate, applied in the field of chemistry, can solve the problems of low yield, complex preparation process and high cost of methyl 3-methoxyacrylate, and achieve high yield High, less reaction steps, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

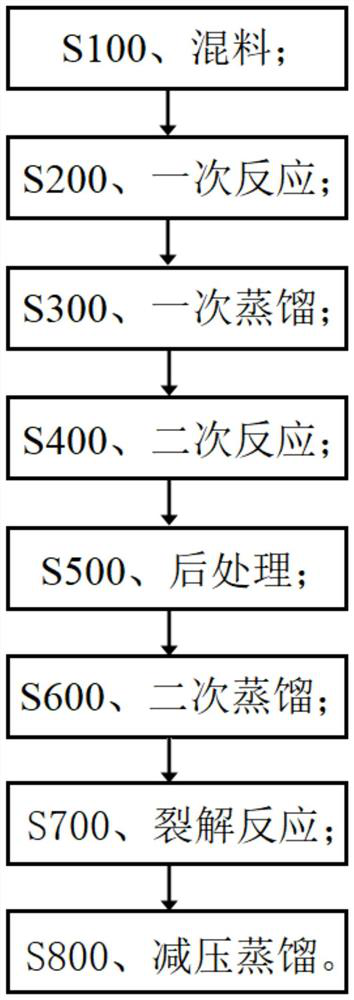

[0035] Refer to attached figure 1 , a kind of preparation method of methyl 3-methoxyacrylate of the present embodiment, 100.0g methyl acetate, 16.5g sodium methoxide, drop in the autoclave, pass into CO gas to 4.0MPa then, reaction temperature is at At 60°C, the CO pressure was controlled at 4.0MPa. After the reaction was completed, the feed liquid was transferred to a distillation pot to distill off excess methyl acetate. Slowly add 131.4g of 10% hydrogen chloride methanol solution dropwise, control the reaction temperature at 40°C, after post-treatment, concentrate, add 0.8g p-toluenesulfonic acid to the concentrated solution, crack at 120-150°C for 6h, and finally depressurize 27.1 g of methyl 3-methoxyacrylate was obtained by rectification, with a purity of 99.2% and a yield of 77.5%. Under the action of strong base sodium alkoxide, methyl acetate makes the alpha carbon on methyl acetate form a carbanion, and then combines with carbon monoxide to form enol sodium salt aft...

Embodiment 2

[0037] Refer to attached figure 1 , a kind of preparation method of methyl 3-methoxyacrylate of the present embodiment, 200.0g methyl acetate, 16.5g sodium methoxide, drop in the autoclave, pass into CO gas to 3.5MPa then, reaction temperature is at 50°C, the CO pressure is controlled at 2.8-3.2MPa. After the reaction is over, the feed liquid is transferred to a distillation pot to distill off excess methyl acetate. Slowly add 109.3g of 10% hydrogen chloride methanol solution dropwise, the reaction temperature is 50°C, after post-treatment, concentrate, add 1.8g of sodium bisulfate to the concentrated solution, crack at 120-150°C for 6h, and finally rectify under reduced pressure Obtained, methyl 3-methoxyacrylate, 25.6 g, purity 98.9%, yield 73.0%.

Embodiment 3

[0039] Refer to attached figure 1, a kind of preparation method of methyl 3-methoxyacrylate of the present embodiment, 300.0g methyl acetate, 16.5g sodium methoxide, drop in the autoclave, pass into CO gas to 3MPa then, reaction temperature is at 50 °C, the CO pressure is controlled at 2.8-3.2MPa, after the reaction is completed, the feed liquid is transferred to a distillation pot to distill off excess methyl acetate. Slowly add 131.4g of 10% hydrogen chloride methanol solution dropwise, the reaction temperature is 45°C, after post-treatment, concentrate, add 1.3g of potassium bisulfate to the concentrated solution, crack at 120-150°C for 6h, and finally rectify under reduced pressure Obtained, methyl 3-methoxyacrylate, 29.2 g, purity 99.5%, yield 83.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com