Lanthanum-based metal organic framework Ln-MOF material and preparation method thereof

An organic framework and lanthanide metal technology, applied in the field of lanthanide metal-organic framework material synthesis, can solve the problems of low rare earth ion sensitization, low quantum efficiency and fluorescence lifetime, etc. The effect of ultra-high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

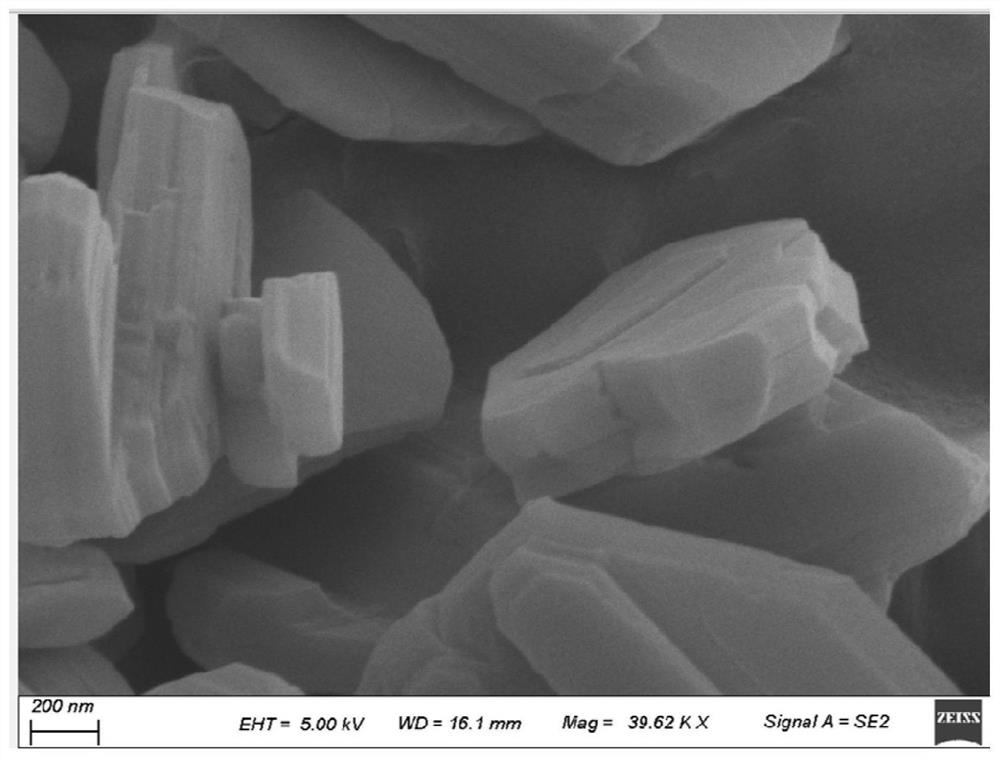

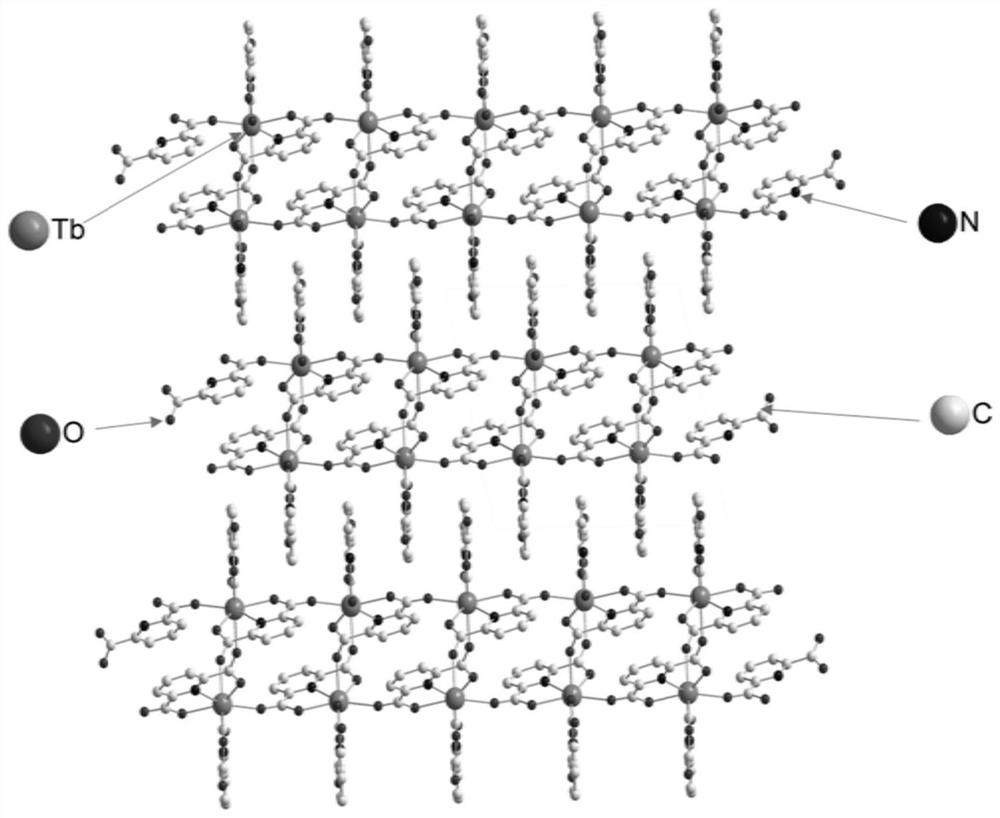

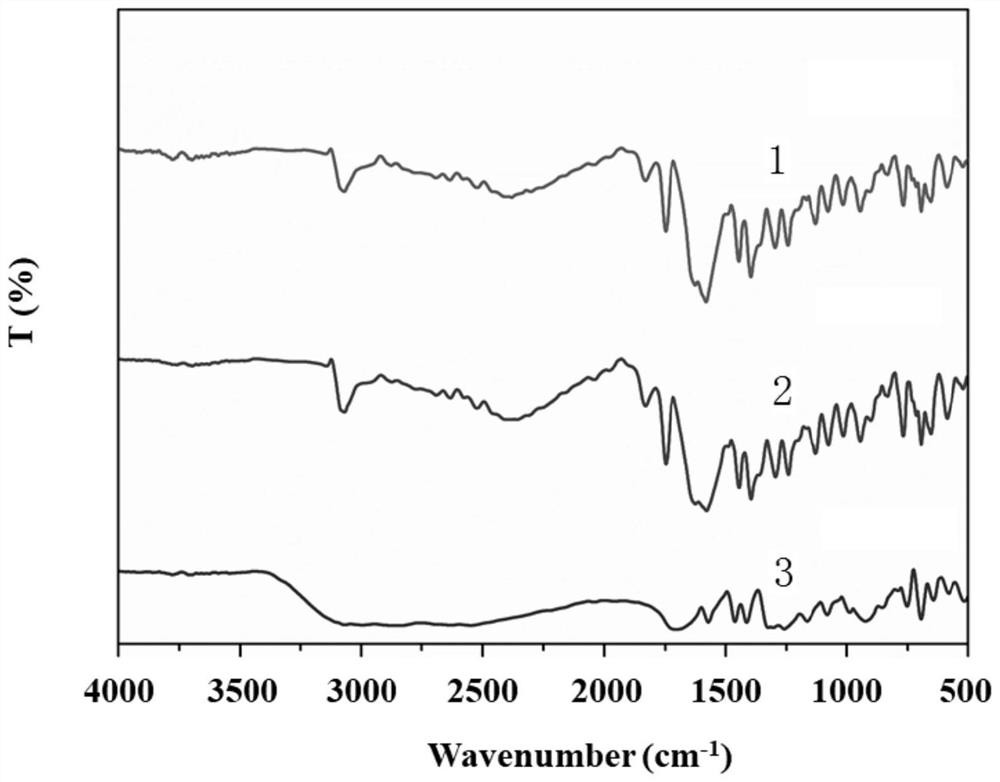

[0021] Specific embodiment one: the present embodiment is a kind of lanthanide metal organic framework Ln-MOF material, and the general chemical formula of the lanthanide metal organic framework Ln-MOF material is [Ln(C 7 h 3 NO 4 )(H(C 7 h 3 NO 4 ))] n , where n>0, and is a positive integer; the crystal system is monoclinic, the space group is P121 / C1, and the unit cell parameters are α=90°, β=102.375°(5), γ=90°, Z=4.

[0022] This embodiment has designed a very suitable ligand (2,6-pyridinedicarboxylic acid H 2 PDA) coordinates with lanthanide elements to obtain a series of isomorphic Ln-MOF materials. The ligands selected in this embodiment have a strong sensitization effect on lanthanide ions, which improves the fluorescence properties of rare earths. The crystal material prepared by the method in the embodiment has very high quantum efficiency and long fluorescence lifetime, and this material can be applied in the fields of sensing and the like.

[0023] The be...

specific Embodiment approach 2

[0027] Specific embodiment two: present embodiment a kind of preparation method of lanthanide metal organic framework Ln-MOF material, it is carried out according to the following steps:

[0028] Add 2,6-pyridinedicarboxylic acid and rare earth salts into the hydrothermal kettle in turn, then add distilled water, and stir for 30min-60min at a stirring speed of 60r / min-80r / min, and then increase the temperature at a rate of 5°C / min~8℃ / min, the temperature is raised to 150℃~180℃, and under the condition of 150℃~180℃, the holding time is 72h~120h, finally washed, centrifuged and dried to obtain lanthanide metal organic Skeleton Ln-MOF material;

[0029] The mass ratio of the 2,6-dipicolinic acid to the rare earth salt is 1:(1.4-1.5).

[0030] This ligand is suitable for all lanthanide metals (La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu) in this method.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is different from Embodiment 2 in that: the volume ratio of the mass of 2,6-dipicolinic acid to distilled water is 1 g:(5-7) mL. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com