Expansion shock insulation glue for body in white and preparation method of expansion shock insulation glue

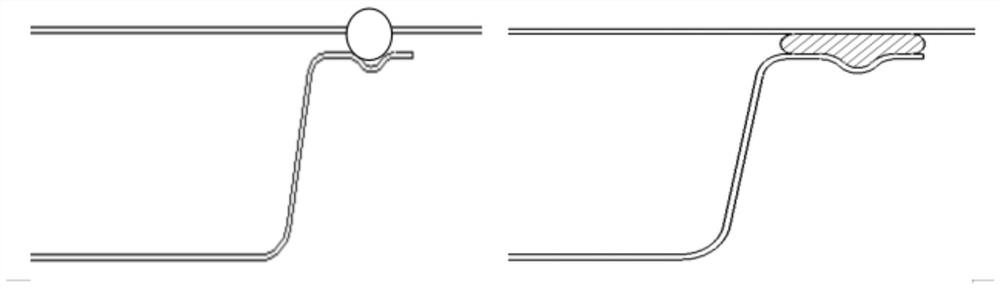

A technology of shock-isolating glue and body-in-white, which is applied in the field of expansion shock-isolating glue production, which can solve problems such as high vibration frequency, large vibration amplitude of sheet metal, and difficulty in supporting strength effectively, and achieve good adhesion, high flexibility, and anti-corrosion Good sag effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

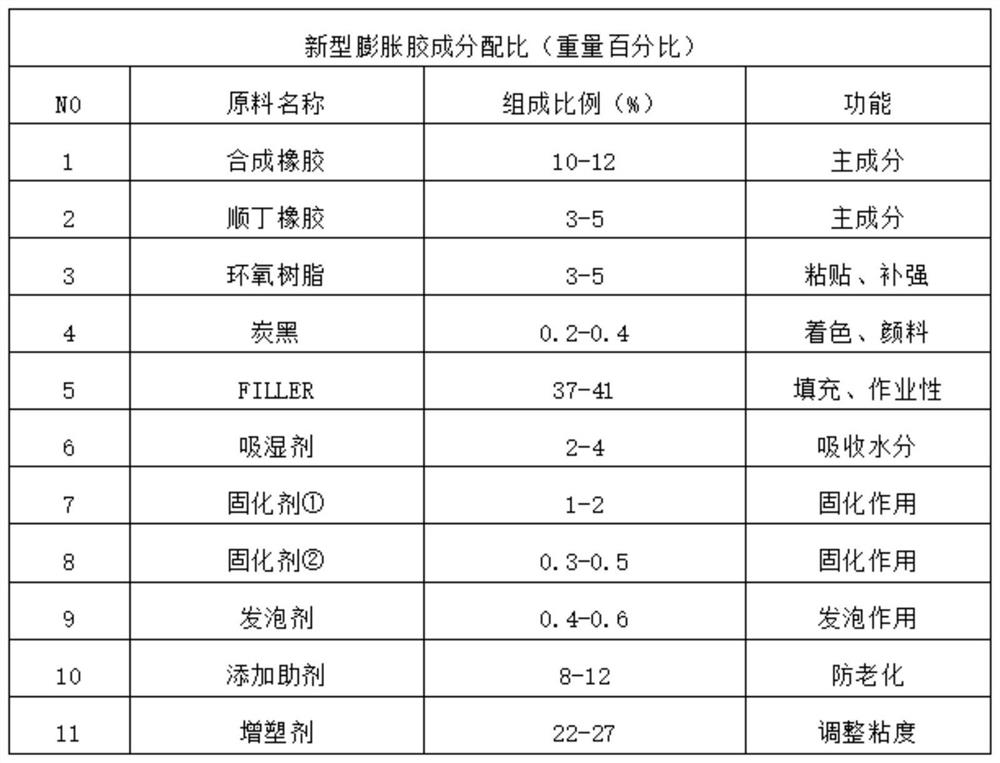

[0040] In this embodiment, a kind of expansion shock-absorbing adhesive for body-in-white includes the following components in weight percentage:

[0041] Synthetic rubber 10%;

[0042] Butadiene rubber 5%;

[0043] Epoxy resin 3%;

[0044] Pigment 0.4%;

[0045] Filler 37%;

[0046] Hygroscopic agent 4%;

[0047] Curing agent 1.3%;

[0048] Foaming agent 0.6%;

[0049] Additive 12%;

[0050] Plasticizer 26.7%.

[0051] In this example, carbon black was used as a pigment to increase rubber coloring.

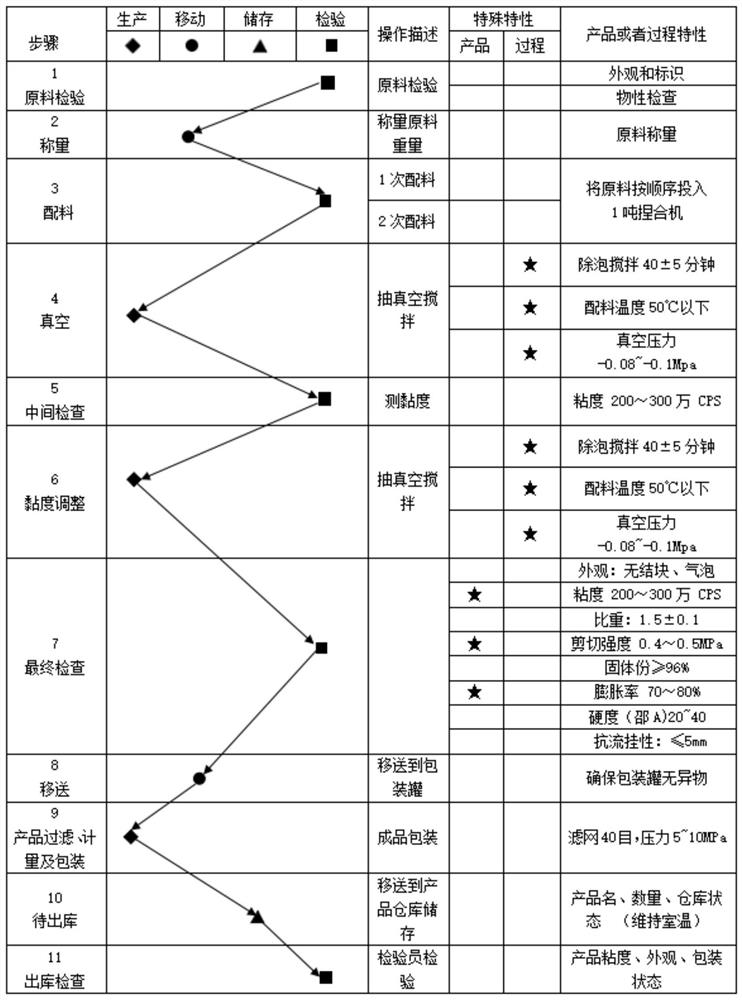

[0052] Its specific preparation method comprises the following steps:

[0053] Step 1: Weigh the ingredients, weigh the raw materials of each component according to the above weight percentage, and check the appearance, identification and physical characteristics of the raw materials to ensure the quality of the raw materials, and put the weighed raw materials into 1 ton compound in order The batching is carried out twice in the machine;

[0054] Step 2: Vacuum stirrin...

Embodiment 2

[0058] In this embodiment, a kind of expansion shock-absorbing adhesive for body-in-white includes the following components in weight percentage:

[0059] Synthetic rubber 12%;

[0060] Butadiene rubber 3%;

[0061] Epoxy resin 5%;

[0062] Pigment 0.2%;

[0063] Filler 39.9%;

[0064] Hygroscopic agent 2%;

[0065] Curing agent 2.5%;

[0066] Foaming agent 0.4%;

[0067] Additive 8%;

[0068] Plasticizer 27%.

[0069] In this example, carbon black was used as a pigment to increase rubber coloring.

[0070] Its specific preparation method is basically the same as that of Example 1.

Embodiment 3

[0072] In this embodiment, a kind of expansion shock-absorbing adhesive for body-in-white includes the following components in weight percentage:

[0073] Synthetic rubber 11%;

[0074] Butadiene rubber 4%;

[0075] Epoxy resin 4%;

[0076] Pigment 0.3%;

[0077] filler 41%;

[0078] Hygroscopic agent 3%;

[0079] Curing agent 2.2%;

[0080] Foaming agent 0.5%;

[0081] Additive 12%;

[0082] Plasticizer 22%.

[0083] In this example, carbon black was used as a pigment to increase rubber coloring.

[0084] Its specific preparation method is basically the same as that of Example 1.

[0085] The performance detection result of the finished product that above-mentioned three embodiments make is as shown in table 1:

[0086]

[0087] Table 1

[0088] Compared with the above test results as Figure 4 According to the technical standards shown, it can be concluded that the performance of the solvent-free reactive expansion rubber based on synthetic rubber can reach high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com