Sterilization device for capsule production

A sterilizing device and capsule technology, applied in water supply devices, sanitary equipment for toilets, heating, etc., can solve the problems of staff burns, capsule burnt, time wasting, etc., achieve uniform heat dissipation, shorten cooling time, reduce Possible effects of burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

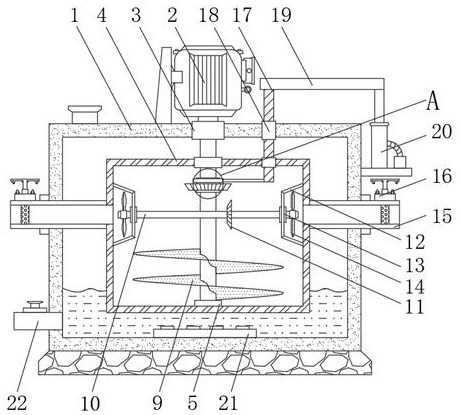

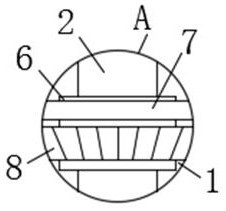

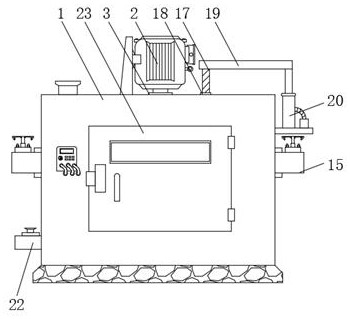

[0033] like Figure 1-3As shown, the present invention provides a technical solution: a sterilizing device for capsule production, comprising a housing 1, the upper surface of the housing 1 is fixedly connected with a motor 2, and the bottom end of the motor 2 passes through two first The bearing 3 is socketed in the second bearing 5, the two first bearings 3 are respectively clamped on the upper surface of the housing 1 and the sterilization box 4, the second bearing 5 is clamped on the lower surface of the inner wall of the sterilization box 4, and the motor 2 The outer surface of the output shaft is sleeved with a sliding sleeve 6, the outer surface of the sliding sleeve 6 is sleeved with a third bearing 7, the outer surface of the sliding sleeve 6 is fixedly connected with the driving wheel 8, and the outer surface of the output shaft of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com