Antibacterial ceramic tile and preparation method thereof

A ceramic tile and antibacterial glaze technology, applied in the field of ceramics, can solve the problem of loss of antibacterial properties, etc., and achieve the effects of a bumper glaze effect, little impact on the production process, and delicate hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] The present invention also provides the preparation method of above-mentioned antibacterial ceramic tile, comprises the following steps:

[0061] S1. Prepare a ceramic tile body, and apply glaze to the ceramic tile body to form a glaze layer;

[0062] S2, forming an inkjet printing layer on the glaze layer;

[0063] S3, applying a protective glaze on the surface of the inkjet printing layer to form a protective glaze layer;

[0064] S4, apply electrostatic antibacterial glaze on the protective glaze layer by electrostatic spraying process to form an electrostatic antibacterial glaze layer, and obtain an antibacterial tile green body;

[0065] S5. After the antibacterial tile green body is dried, it is sent to a kiln for sintering to obtain a finished antibacterial tile.

[0066] The antibacterial ceramic tile provided by the invention has a simple preparation process and convenient operation, and the glazing process has no negative impact on the color and feel of the ...

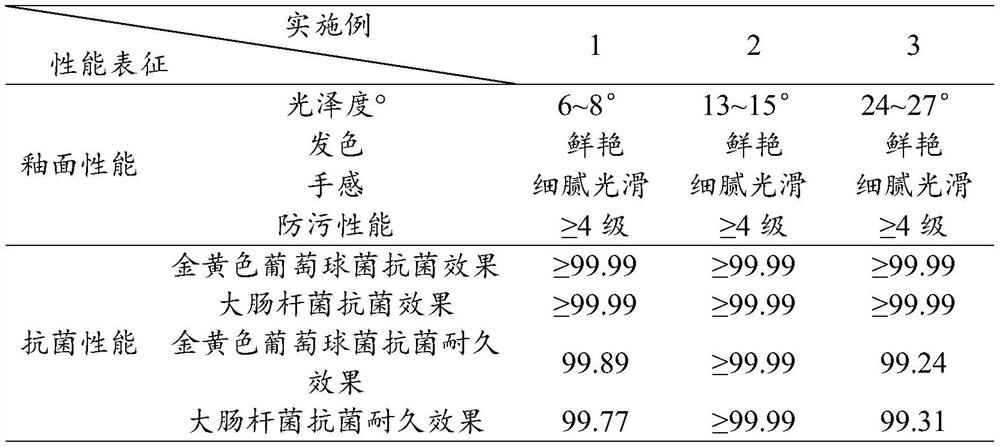

Embodiment 1

[0079] An antibacterial ceramic tile, the body of the ceramic tile is sequentially provided with a surface glaze layer, an inkjet printing layer, a protective glaze layer and an electrostatic antibacterial glaze layer, and the glazing method of the electrostatic antibacterial glaze layer is an electrostatic spraying glaze process.

[0080] The raw materials of the electrostatic antibacterial glaze include by mass percentage: antibacterial powder 20%, Al 2 o 3 3%, kaolin 5%, electrostatic additive 15%, humectant 7%, dispersant 1%, and the balance is water.

[0081] The surface glaze includes 40% of potassium feldspar, 5% of kaolin, 3% of dolomite, 10% of aluminum oxide, 15% of talc, 5% of zinc oxide, 12% of barium carbonate and 10% of zirconium silicate by mass percentage.

[0082] The raw materials of the protective glaze include 38% of potassium feldspar, 15% of dolomite, 15% of kaolin, 10% of quartz, 10% of talc, 6% of zinc oxide, 6% of strontium carbonate, 2-6% of barium ...

Embodiment 2

[0095] An antibacterial ceramic tile, the body of the ceramic tile is sequentially provided with a surface glaze layer, an inkjet printing layer, a protective glaze layer and an electrostatic antibacterial glaze layer, and the glazing method of the electrostatic antibacterial glaze layer is an electrostatic spraying glaze process.

[0096] The raw materials of the electrostatic antibacterial glaze include by mass percentage: antibacterial powder 40%, Al 2 o 3 1%, kaolin 5%, electrostatic additive 11%, humectant 4%, dispersant 0.3%, and the balance is water.

[0097] The surface glaze includes 30% of potassium feldspar, 3% of kaolin, 3% of dolomite, 14% of aluminum oxide, 20% of talc, 10% of zinc oxide, 15% of barium carbonate and 15% of zirconium silicate by mass percentage.

[0098] The raw material composition of the protective glaze includes by mass fraction: 36% of potassium feldspar, 15% of dolomite, 12% of kaolin, 10% of quartz, 9% of talc, 8% of zinc oxide, 10% of str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| antifouling properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com