Process for producing soft carbon black by oil furnace method hard reaction furnace

A technology of soft carbon black and reaction furnace, which is applied in the direction of fibrous fillers, etc., can solve the problems of increasing costs, achieve the effects of increasing air-oil ratio, obvious economic benefits, and increasing gas flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

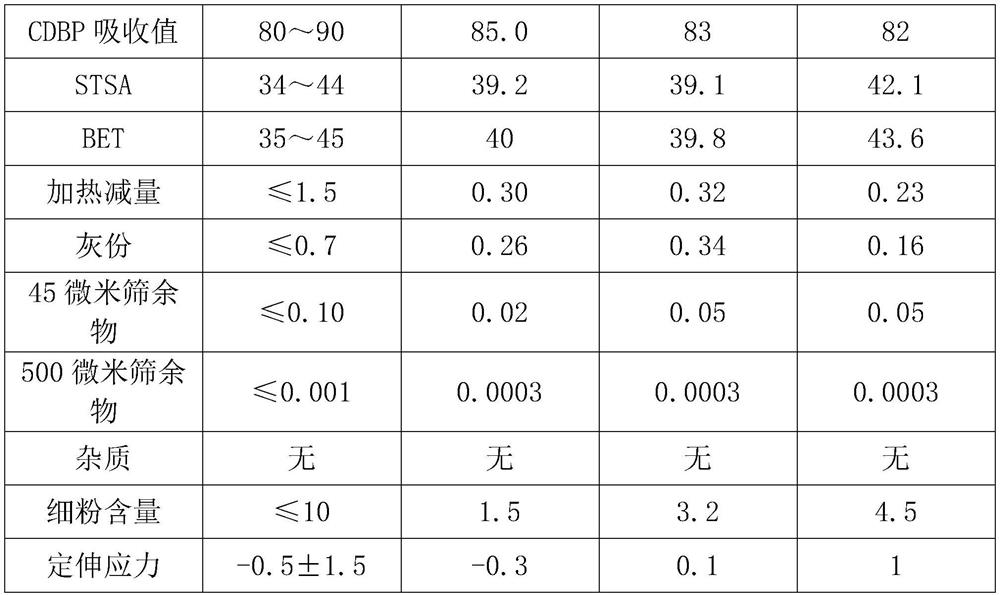

Embodiment 1

[0025] A kind of technology that oil furnace method hard reaction furnace produces N660 soft carbon black, comprises the following steps:

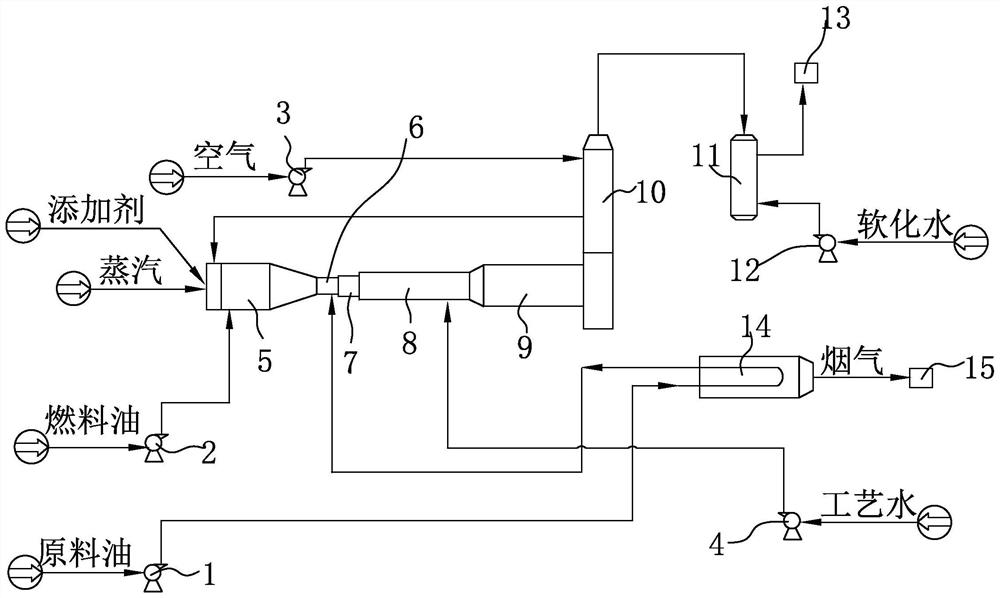

[0026] 1. The reaction furnace is a 40,000-ton hard horizontal furnace, including a combustion section 5, a throat pipe 6, a reaction section 7, a quenching section 8 and a gasification section 9 connected in sequence.

[0027] 2. After being pressurized by the fuel pump 2, the fuel oil is sprayed radially into the inner cavity of the combustion section 5 of the hard reaction furnace, that is, the combustion chamber. After being pressurized by the main supply fan 3 and preheated by the air preheater 10, it enters The temperature of the combustion section 5 is 700°C for mixed combustion with high-temperature air, and the combustion temperature in the combustion chamber is controlled at 1600°C. The fuel is ethylene tar, wherein the dosage of ethylene tar is 600kg / h, and the intake rate of high-temperature air is 14700Nm 3 / h.

[0028] 3. Th...

Embodiment 2

[0036] A kind of technology that oil furnace method hard reaction furnace produces N660 soft carbon black, comprises the following steps:

[0037] 1. The reaction furnace is a 40,000-ton hard horizontal furnace, including a combustion section 5, a throat pipe 6, a reaction section 7, a quenching section 8 and a gasification section 9 connected in sequence.

[0038] 2. After the fuel oil is pressurized by the fuel pump 2, it is radially sprayed into the combustion chamber of the hard reaction furnace, pressurized by the main supply fan 3, and then preheated by the air preheater 10, and the temperature entering the combustion section 5 is 705 ℃ high-temperature air mixed combustion, control the combustion temperature in the combustion chamber at 1600 ℃, the fuel is anthracene oil, wherein the dosage of anthracene oil is 597kg / h, and the intake of high-temperature air is 14700Nm 3 / h.

[0039] 3. The steam is axially sprayed into the combustion chamber from the front of the reac...

Embodiment 3

[0047] A kind of technology that oil furnace method hard reaction furnace produces N550 soft carbon black, comprises the following steps:

[0048] 1. The reaction furnace is a 40,000-ton hard horizontal furnace, including combustion section 5, throat 6, reaction 7, quenching section 8 and gasification section 9 connected in sequence.

[0049] 2. After the fuel oil is pressurized by the fuel pump 2, it is sprayed radially into the combustion section 5 of the hard reaction furnace. After being pressurized by the main supply fan 3 and preheated by the air preheater 10, the temperature entering the combustion section 5 is Mixed combustion with high temperature air at 670°C, control the combustion temperature in the combustion chamber at 1680°C, the fuel is ethylene tar, the dosage of ethylene tar is 625kg / h, and the intake of high temperature air is 13800Nm 3 / h.

[0050] 3. The steam is axially sprayed into the combustion chamber from the front of the reaction furnace, and forms a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com