Water-based high-gloss wear-resistant floor paint and preparation method thereof

A floor paint and high-gloss technology, used in coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., can solve the problems of wear resistance and poor gloss of floor paint, and achieve good gloss, continuous coating, high glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

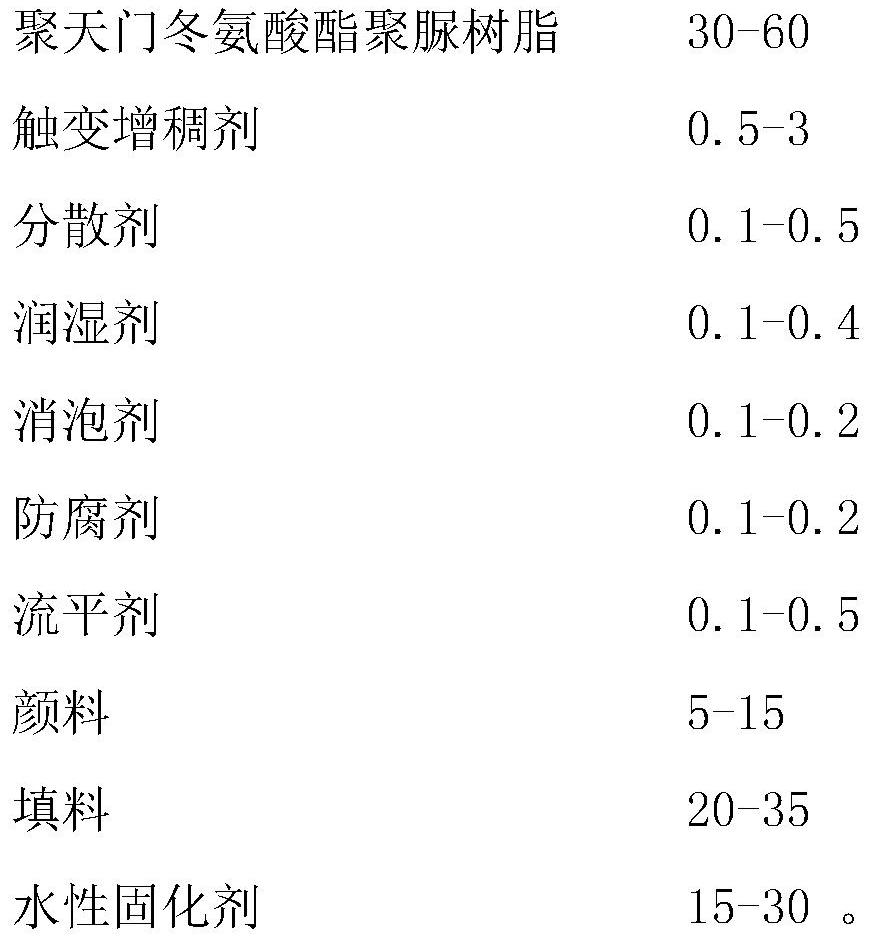

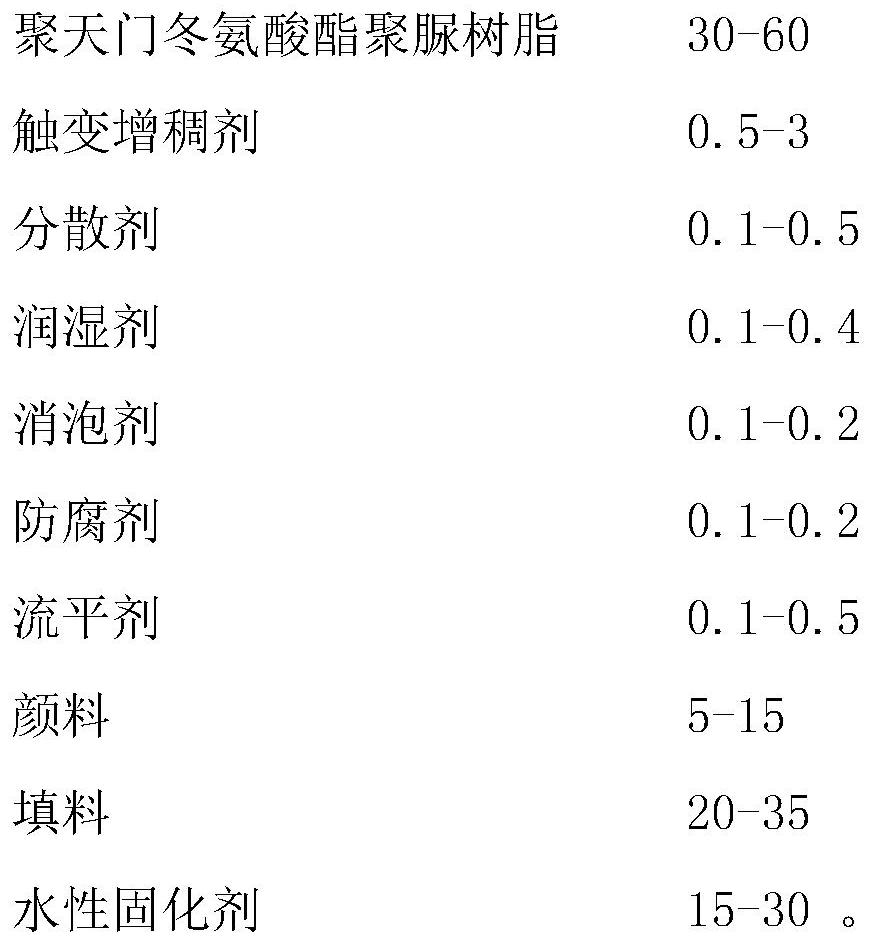

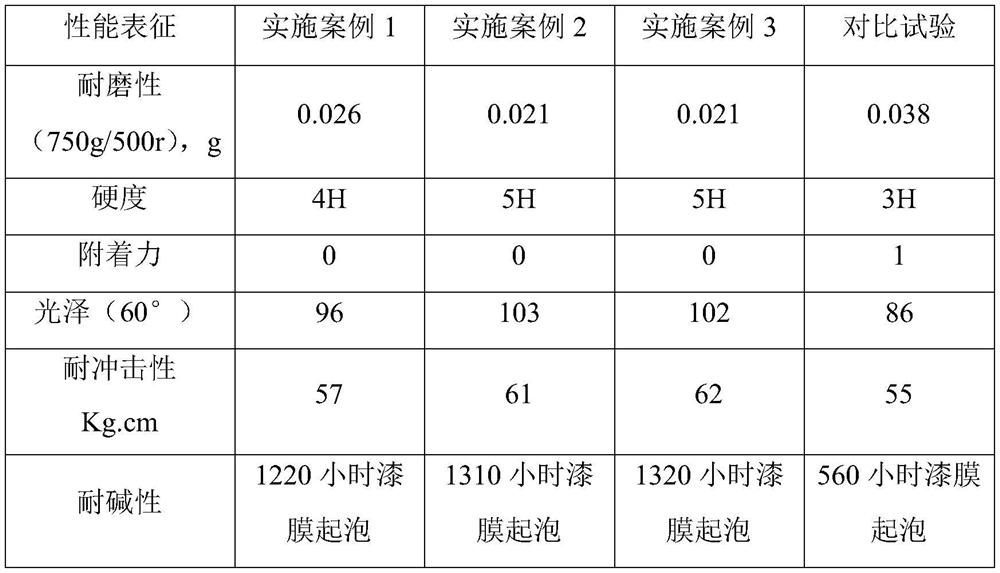

[0028] A water-based high-gloss wear-resistant floor paint, by weight parts, polyaspartate polyurea resin 45, dispersant 0.4, wetting agent 0.2, defoamer 0.1, preservative 0.1, thixotropic thickener 1.1, leveling agent 0.1, nano-titanium dioxide 10, silicon carbide 10, quartz 10, high-gloss barium sulfate 15, water-based curing agent 22; its preparation method is as follows;

[0029] Step 1: Weigh polyaspartic ester polyurea resin 45, and add in sequence at a stirring speed of 300-500 rpm, dispersant 0.4, wetting agent 0.2, defoamer 0.1, thixotropic thickening Agent 1.1, leveling agent 0.1, preservative 0.1, stir for 1-2min after adding;

[0030] Step 2: Increase the rotation speed to 1000-1200 rpm, disperse for 20-30 minutes, reduce the rotation speed to 500-700 rpm, add nano-titanium dioxide 10, silicon carbide 10, quartz 10, high-gloss barium sulfate 15, and water-based curing agent 22 in sequence , increase the speed to 1200-1500 rpm, disperse to a fineness of ≤50 μm, and...

Embodiment 2

[0032] A water-based high-gloss wear-resistant floor paint, by weight parts, polyaspartic acid ester polyurea resin 50, dispersant 0.4, wetting agent 0.2, defoamer 0.1, preservative 0.1, thixotropic thickener 1.3, leveling agent 0.1, nano-titanium dioxide 10, silicon carbide 13, quartz 12, high-gloss barium sulfate 10, water-based curing agent 25; its preparation method is as follows;

[0033] Step 1: Weigh 50 polyaspartic ester polyurea resins, and add dispersant 0.4, wetting agent 0.2, defoamer 0.1, thixotropic thickening in the state of stirring at a speed of 300-500 rpm Agent 1.3, leveling agent 0.1, preservative 0.1, stir for 1-2min after adding;

[0034] Step 2: Increase the rotation speed to 1000-1200 rpm, disperse for 20-30 minutes, reduce the rotation speed to 500-700 rpm, add nano-titanium dioxide 10, silicon carbide 13, quartz 12, high-gloss barium sulfate 10, and water-based curing agent 25 in sequence , increase the speed to 1200-1500 rpm, disperse to a fineness ...

Embodiment 3

[0036] A water-based high-gloss wear-resistant floor paint, by weight parts, polyaspartic acid ester polyurea resin 55, dispersant 0.4, wetting agent 0.2, defoamer 0.1, preservative 0.1, thixotropic thickener 1.3, leveling agent 0.1, nano-titanium dioxide 10, silicon carbide 15, quartz 15, high-gloss barium sulfate 5, water-based curing agent 27; its preparation method is as follows;

[0037] Step 1: Weigh polyaspartic acid ester polyurea resin 55, and add in sequence at a stirring speed of 300-500 rpm, dispersant 0.4, wetting agent 0.2, defoamer 0.1, thixotropic thickening Agent 1.3, leveling agent 0.1, preservative 0.1, stir for 1-2min after adding;

[0038] Step 2: Increase the rotation speed to 1000-1200 rpm, disperse for 20-30 minutes, reduce the rotation speed to 500-700 rpm, add nano-titanium dioxide 10, silicon carbide 15, quartz 15, high-gloss barium sulfate 5, and water-based curing agent 27 in sequence , increase the speed to 1200-1500 rpm, disperse to a fineness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com