Method for forming organic nanowire array and organic nanowire array

A technology of organic nanowires and arrays, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of reducing difficulty and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] In this example, the 8-hydroxyquinoline aluminum nanowire array 1 is prepared, and the specific process is as follows:

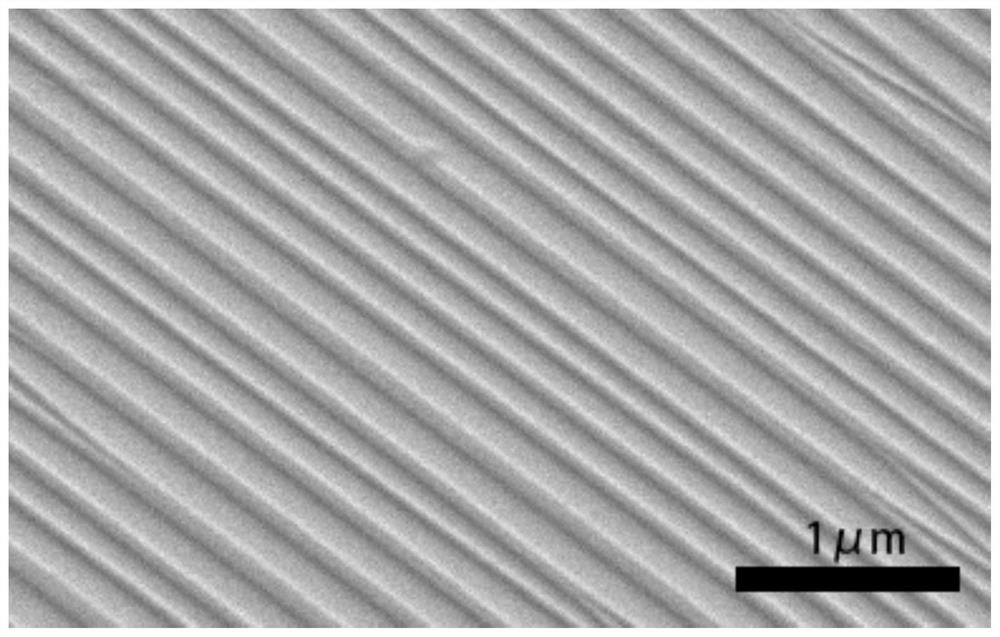

[0081] (1) Take the single crystal M-face sapphire substrate as the raw material, put it into acetone, remove the oil on the surface through an ultrasonic cleaner, and then blow the surface with dry nitrogen; put the dried M-face sapphire substrate into ethanol , remove the residual acetone solvent, and blow the surface with nitrogen; put the dried M-plane sapphire substrate into deionized water, remove the organic solvent on the surface, dry the surface with nitrogen, and put the cleaned M-plane sapphire substrate into In the high-temperature box-type furnace, the temperature was raised to 1600°C at a speed of 5-15°C / min, and the temperature was kept at 1600°C for 10 hours, and then cooled to room temperature with the high-temperature box-type furnace. channel array;

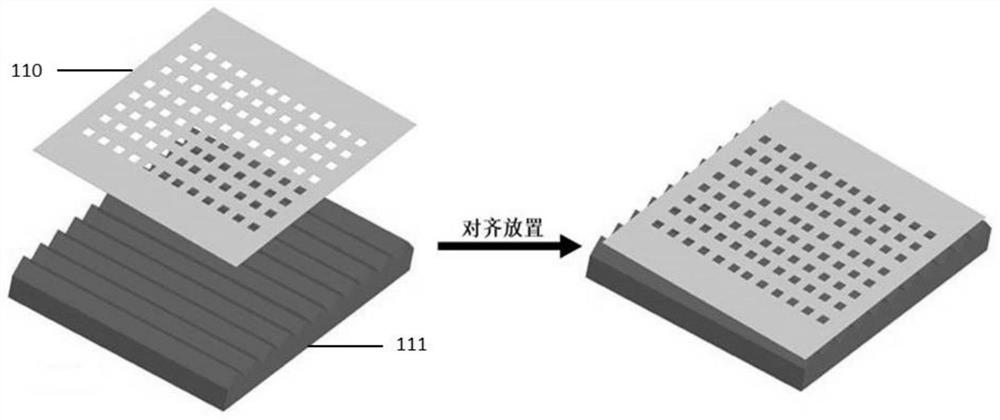

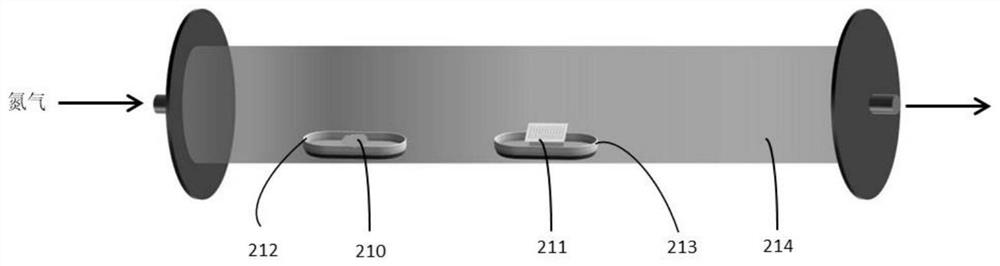

[0082] (2) Adsorb the M-face sapphire substrate with parallel channel arrays in s...

Embodiment 2

[0088] In this example, the 8-hydroxyquinoline aluminum nanowire array 2 is prepared. The difference from Example 1 is that the hole diameter of the hollow mask is 300x300 μm 2 , the hole distance is 200μm. The specific process is:

[0089] (1) Take the single crystal M-face sapphire substrate as the raw material, put it into acetone, remove the oil on the surface through an ultrasonic cleaner, and then blow the surface with dry nitrogen; put the dried M-face sapphire substrate into ethanol , remove the residual acetone solvent, and blow the surface with nitrogen; put the dried M-plane sapphire substrate into deionized water, remove the organic solvent on the surface, dry the surface with nitrogen, and put the cleaned M-plane sapphire substrate into In the high-temperature box-type furnace, the temperature was raised to 1600°C at a speed of 5-15°C / min, and the temperature was kept at 1600°C for 10 hours, and then cooled to room temperature with the high-temperature box-type f...

Embodiment 3

[0096] In this example, the 8-hydroxyquinoline aluminum nanowire array 3 is prepared. The difference from Example 1 is that the hole diameter of the hollow mask is 200x200 μm 2 , the hole distance is 300μm. The specific process is:

[0097] (1) Take the single crystal M-face sapphire substrate as the raw material, put it into acetone, remove the oil on the surface through an ultrasonic cleaner, and then blow the surface with dry nitrogen; put the dried M-face sapphire substrate into ethanol , remove the residual acetone solvent, and blow the surface with nitrogen; put the dried M-plane sapphire substrate into deionized water, remove the organic solvent on the surface, dry the surface with nitrogen, and put the cleaned M-plane sapphire substrate into In the high-temperature box-type furnace, the temperature was raised to 1600°C at a speed of 5-15°C / min, and the temperature was kept at 1600°C for 10 hours, and then cooled to room temperature with the high-temperature box-type f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com