Radiator with double phase change cavities

A radiator and dual-phase change technology, applied in indirect heat exchangers, cooling/heating devices of lighting devices, lighting and heating equipment, etc. Dry out and other problems, to achieve the power density heat dissipation requirements, improve heat extraction capacity, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

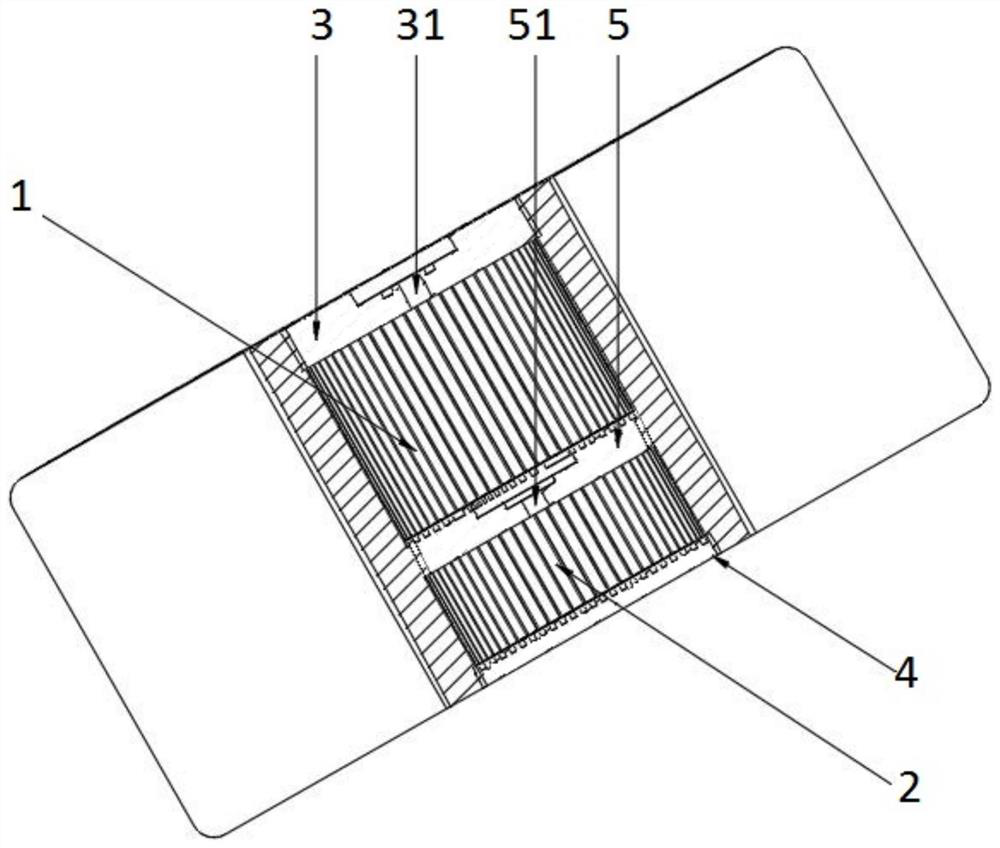

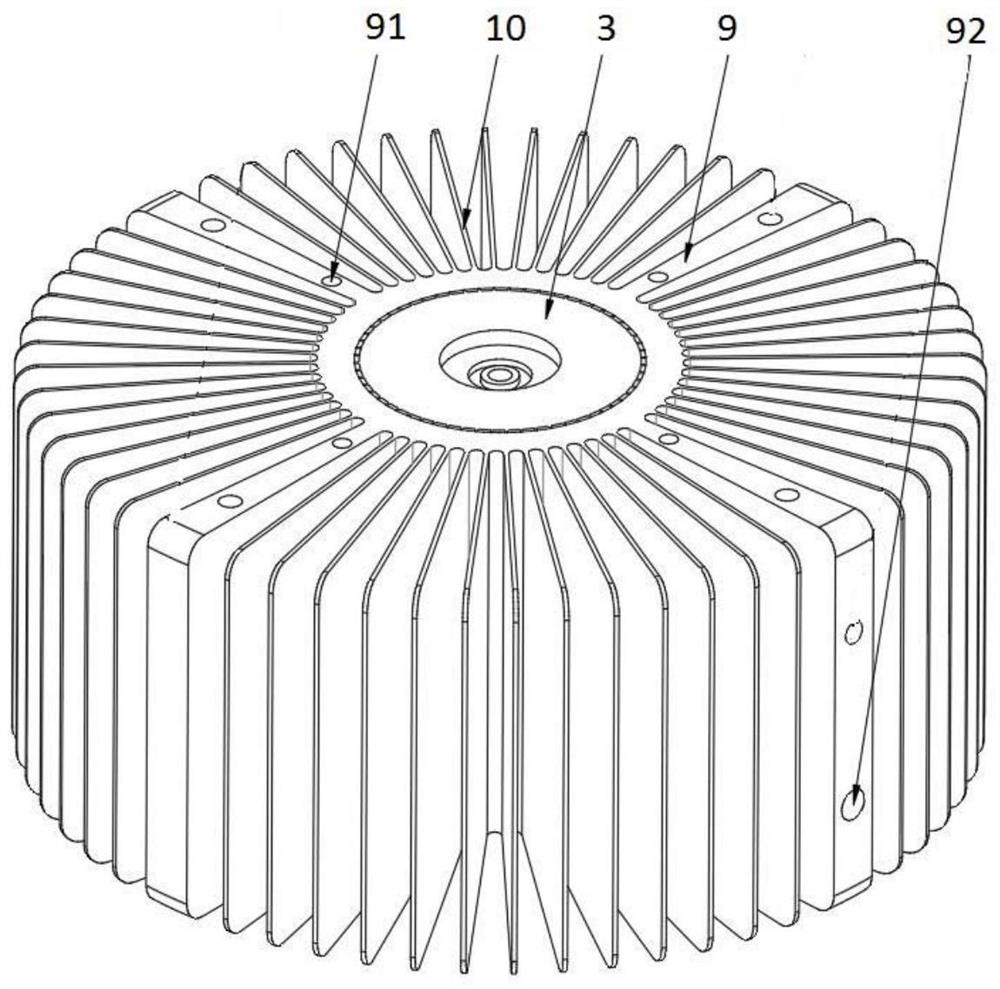

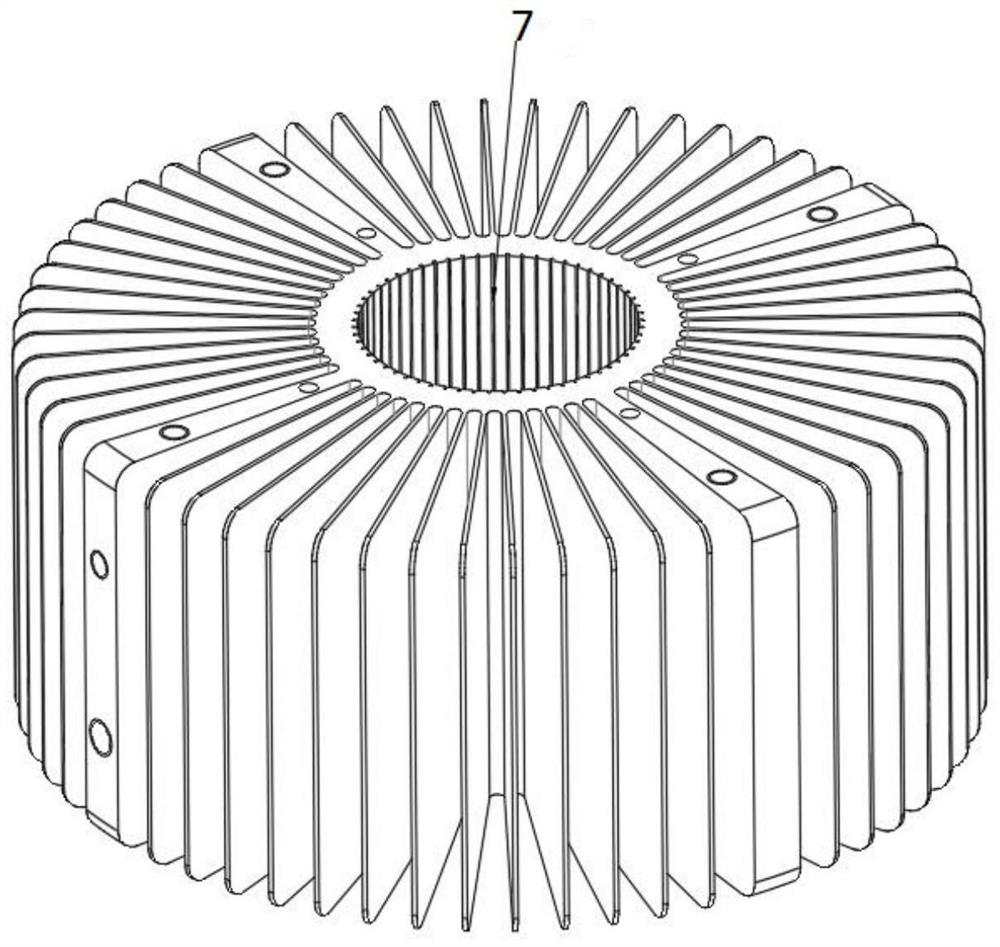

[0035] Such as Figure 1~3 As shown, a radiator with a dual-phase change cavity, the main structure is sunflower-shaped, the material is at least one of metal, alloy, plastic or metal-plastic, the outer diameter is 20~500mm, the inner diameter is 10~400mm, the total height 20~500mm. It includes an upper cavity body 1 , a lower cavity body 2 , an upper cover plate 3 , a lower cover plate 4 and a sandwich plate 5 .

[0036] The upper cover plate 3 has an outer diameter of 10-400 mm and a thickness of 5-15 mm. It cooperates with the upper cavity 1 and is arranged on the top of the upper cavity 1. The upper surface center of the upper cover plate 3 is provided with a first sealing port 31, such as Figure 6 shown. The lower cover plate 4 has an outer diameter of 10-400 mm and a thickness of 5-15 mm, which cooperates with the lower cavity 2 and is arranged at the bottom of the lower cavity 2 .

[0037] The sandwich plate 5 has an outer diameter of 10-400 mm and a thickness of 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com