Preparation method and application of high-melt-strength polylactic acid

A high melt strength, polylactic acid technology, applied in the field of polylactic acid preparation, can solve the problems of low foaming ratio, difficult industrialization, and high temperature, and achieve the effects of increased cell density, enhanced crystallization performance, and increased foaming ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

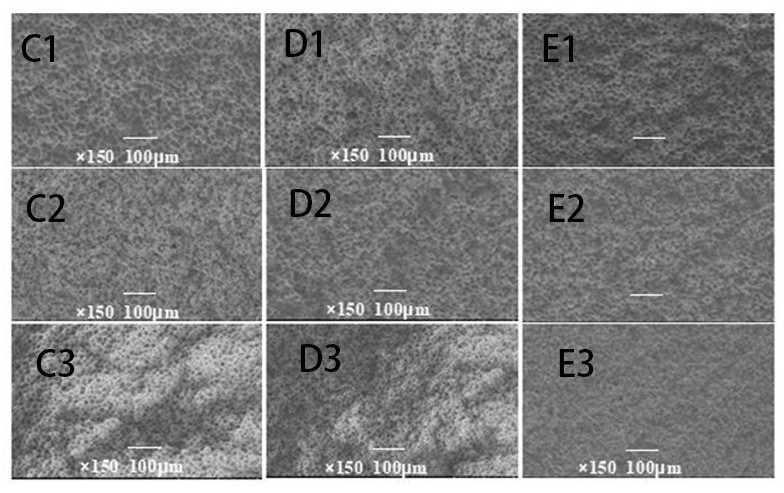

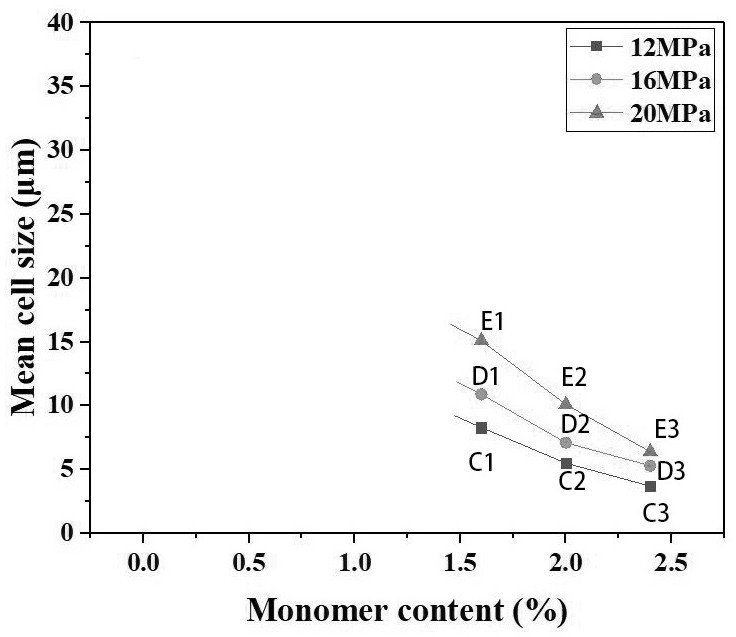

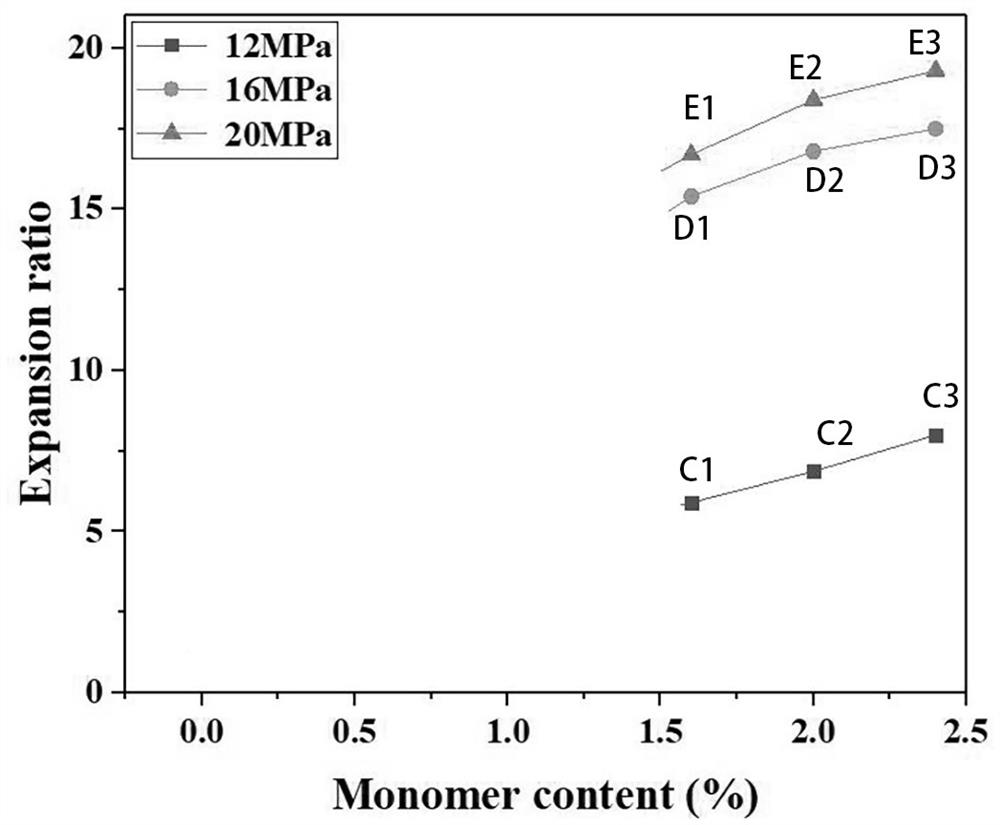

Embodiment 1

[0038] A method for preparing high melt strength polylactic acid, including the following steps:

[0039] (1) After drying at 80 ° C for 6 h, it was mixed with peroxide, acetone, and three functional groups, and a mixture was mixed, and the trifunomacrylate, sterior oxidation dibenzoyl, acetone, The mass ratio is 32: 1: 5, the addition of the three-functional group acrylate is 1.6% of polylactic acid, polylactic acid (2003d), the melt index Mi is 6.0 g / 10 min, the trifunctional acrylate can be three Hydroxymethyl propane triacrylate;

[0040] (2) Place the mixture in an oven for secondary dry, the secondary drying to bake 0.5h in an oven at 92 ° C for 0.5h in an oven for baking 30s, grafted modified high melt Strength polylactic acid, as a A1 substance, extruded molding obtained (grafted modified) high melt strength polylactic acid blend particles B1, the extruded molded temperature is 155 ° C, and the rotational speed is 30 rpm.

[0041] The high melt strength polylactic acid b...

Embodiment 2

[0045] A method for preparing high melt strength polylactic acid, including the following steps:

[0046] (1) After drying at 80 ° C for 6 h, it was mixed with peroxide, acetone, and three functional groups, and a mixture was mixed, and the trifunomacrylate, sterior oxidation dibenzoyl, acetone, The mass ratio is 32: 1: 5, the addition of the three-functional group of acrylate is 2.0% of polylactic acid, polylactic acid (2003d), and the melt index Mi is 6.0 g / 10 min, and the trifunction acrylate can be three Hydroxymethyl propane triacrylate;

[0047] (2) Place the mixture in an oven for secondary drying, the secondary drying to bake 40min in an oven at 92 ° C for 40 minutes to bake 30s, grafted modified high melt strength Polylactic acid, as a A2 substance, extruded molded (grafted modified) high melt strength polylactic acid blend particles B2, the extruded molded temperature is 165 ° C, and the rotational speed is 30 rpm.

[0048] The high melt strength polylactic acid blend ...

Embodiment 3

[0052] A method for preparing high melt strength polylactic acid, including the following steps:

[0053] (1) After drying at 80 ° C for 6 h, it was mixed with peroxide, acetone, and three functional groups, and a mixture was mixed, and the trifunomacrylate, sterior oxidation dibenzoyl, acetone, The mass ratio is 32: 1: 5, the addition of the three-functional junkate is 2.4%, polylactic acid (2003d), and the melt index Mi is 6.0 g / 10 min, the trifunctional acrylate can be three Hydroxymethyl propane triacrylate;

[0054] (2) Place the mixture in an oven for secondary drying, the secondary drying to bake 60 min in an oven at 92 ° C for 60 minutes to bake 30s, grafting modified high melt strength Polylactic acid, as A3 substance, extruded molding obtained (grafted modified) high melt strength polylactic acid blend particles B3, the extruded molding temperature of 185 ° C, and the rotational speed is 30 rpm.

[0055] The high melt strength polylactic acid blend particles were place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com