Bio-based antibacterial adhesive and preparation method thereof

A bio-based and adhesive technology, applied in the direction of adhesives, etc., can solve the problems of complex raw material composition and preparation process, hidden dangers of nano-silver to human health, and insufficient safety of heavy metals, and achieve good antibacterial and biocompatibility. Significant antibacterial activity, The effect of improving the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A preparation method of a bio-based antibacterial adhesive, the preparation method comprising the following steps:

[0031] S1. Add the reactant 5',5-diallyl-2,2'-biphenyldiol and 3,6-dioxa-1,8-octanedithiol to toluene solvent, at room temperature Stir at 300-500r / min to completely dissolve the reactant in the toluene solution to obtain a mixed solution;

[0032] Among them, the mass fraction of 5',5-diallyl-2,2'-biphenyldiol and 3,6-dioxa-1,8-octanedithiol is 60-70:30- 40, the ratio of mass and number of reactants to solvent is 10-20:80-90;

[0033] S2. Add catalyst 2-isopropylthioxanthone to the mixed solution obtained in step S1, stir until completely dissolved, wherein the mass parts of catalyst and reactant are 1-2:100;

[0034] S3. At room temperature, the mixed solution added with the catalyst obtained in step S2 is stirred at a stirring speed of 800-1000r / min, and placed under a 365nm light source to irradiate for 0.5h to obtain a product solution. The reactio...

Embodiment 1

[0040] The preparation method of bio-based antibacterial adhesive:

[0041] (1) Mix 6.0g 5',5-diallyl-2,2'-diphenol (CAS No.: 528-43-8) and 4.0g 3,6-dioxa-1,8- Octanedithiol is added in the toluene of 45g, at room temperature, reactant is dissolved completely with 300r / min stirring;

[0042] (2) Add 100 mg of 2-isopropylthioxanthone ITX (CAS No.: 5495-84-1) to the mixed solution obtained in step (1) and stir until completely dissolved;

[0043] (3) Stir the mixed solution obtained in step (2) at room temperature at a stirring speed of 800 r / min, and irradiate with a 365 nm light source for 0.5 h.

[0044] (4) The product solution that step (3) obtains is joined in the 500ml cyclohexane, after stirring 10min, leave standstill;

[0045] (5) Remove the supernatant of the solution obtained in step (4), collect the colloidal precipitate in the lower layer, and dry at 30°C and 0.09Mpa for 30min to obtain the bio-based antibacterial adhesive.

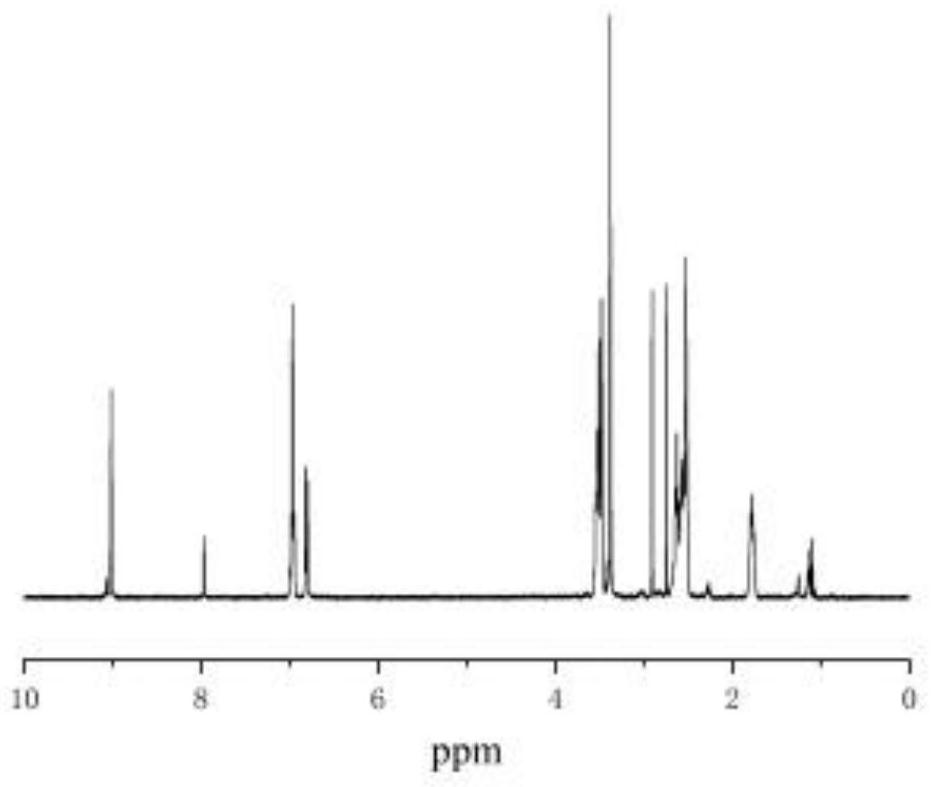

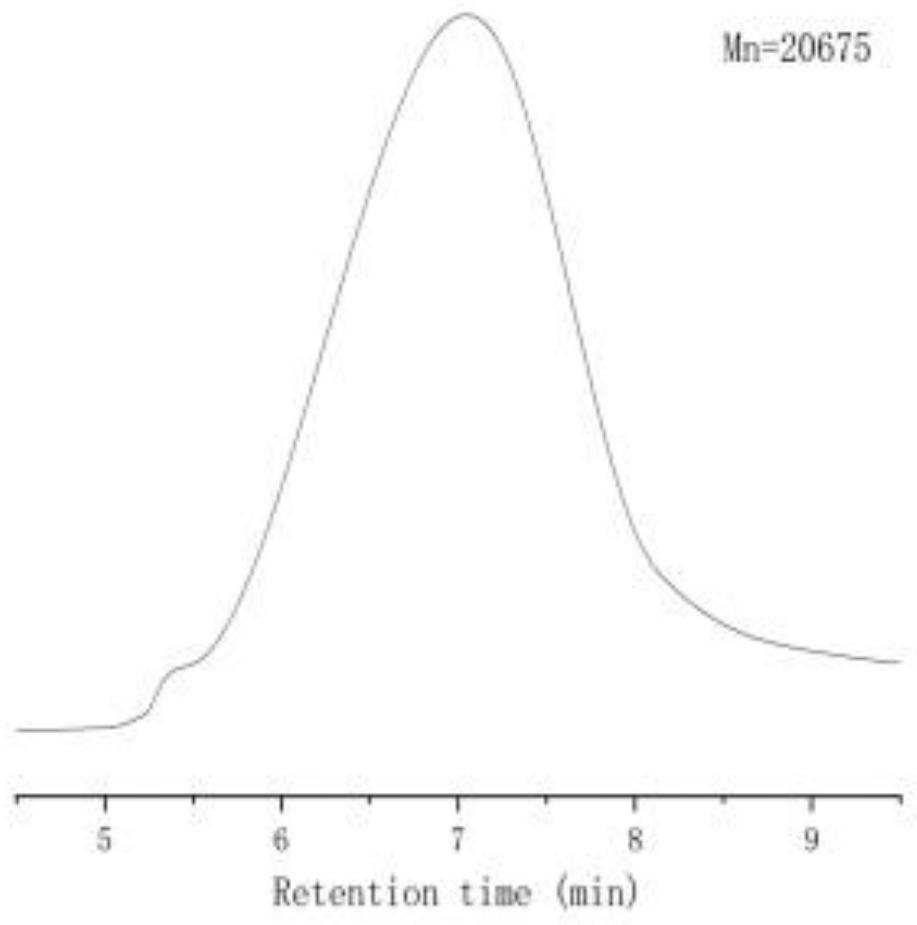

[0046] see figure 1 Shown is the nu...

Embodiment 2

[0051] The preparation method of bio-based antibacterial adhesive:

[0052] (1) Mix 7.0g 5',5-diallyl-2,2'-diphenol (CAS No.: 528-43-8) and 7.0g 3,6-dioxa-1,8- Octanedithiol is added in the toluene of 90g, at room temperature, with 500r / min stirring, reactant is dissolved completely;

[0053] (2) Add 200 mg of 2-isopropylthioxanthone ITX (CAS No.: 5495-84-1) to the mixed solution obtained in step (1) and stir until completely dissolved;

[0054] (3) Stir the mixed solution obtained in step (2) at room temperature at a stirring speed of 1000 r / min, and irradiate with a 365 nm light source for 0.5 h.

[0055] (4) The product solution that step (3) obtains is joined in the 900ml cyclohexane, after stirring 10min, leave standstill;

[0056] (5) Remove the supernatant of the solution obtained in step (4), collect the colloidal precipitate in the lower layer, and dry at 30°C and 0.09Mpa for 30min to obtain the bio-based antibacterial adhesive.

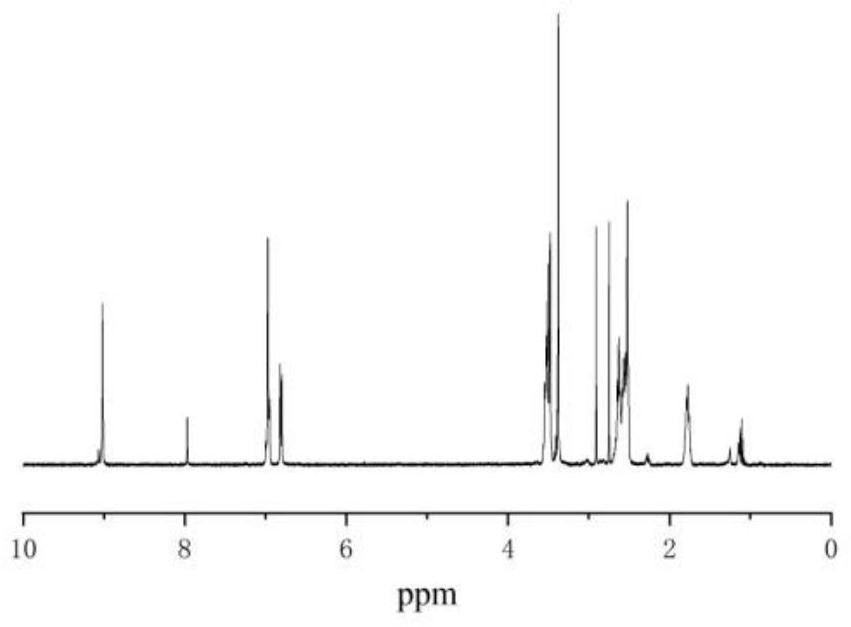

[0057] See image 3 Shown is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com