Semi-conductive shielding material and preparation method and application thereof

A shielding material, semi-conductive technology, applied in the semi-conductive shielding material for silane cross-linked cable insulation and its preparation, semi-conductive shielding material and its preparation field, can solve the problems such as the interface air gap between the outer shielding layer and the insulating layer, and achieve the preparation steps Simple and easy to implement, easy to use raw materials, and the effect of improving the withstand voltage level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The present invention also provides a method for preparing the semiconductive shielding material according to the present invention, which includes the step of mixing the components of the semiconductive shielding material.

[0051] Specifically, the method includes the following steps:

[0052] Mix cracked PE wax, dispersant, antioxidant and silicone to obtain a premixed product;

[0053] After banburying ethylene-butyl acrylate copolymer, maleic anhydride grafted polyethylene, ethylene-octene copolymer and conductive carbon black, they are mixed with the premixed product to obtain a jelly;

[0054] The jelly is extruded into strands and granulated to obtain a semi-conductive shielding material.

[0055] Further, the method may include the following steps:

[0056] (1) Add cracking PE wax, dispersant, antioxidant and silicone to a mixer for premixing to obtain a premixed product;

[0057] (2) Put ethylene-butyl acrylate copolymer, maleic anhydride grafted polyethyle...

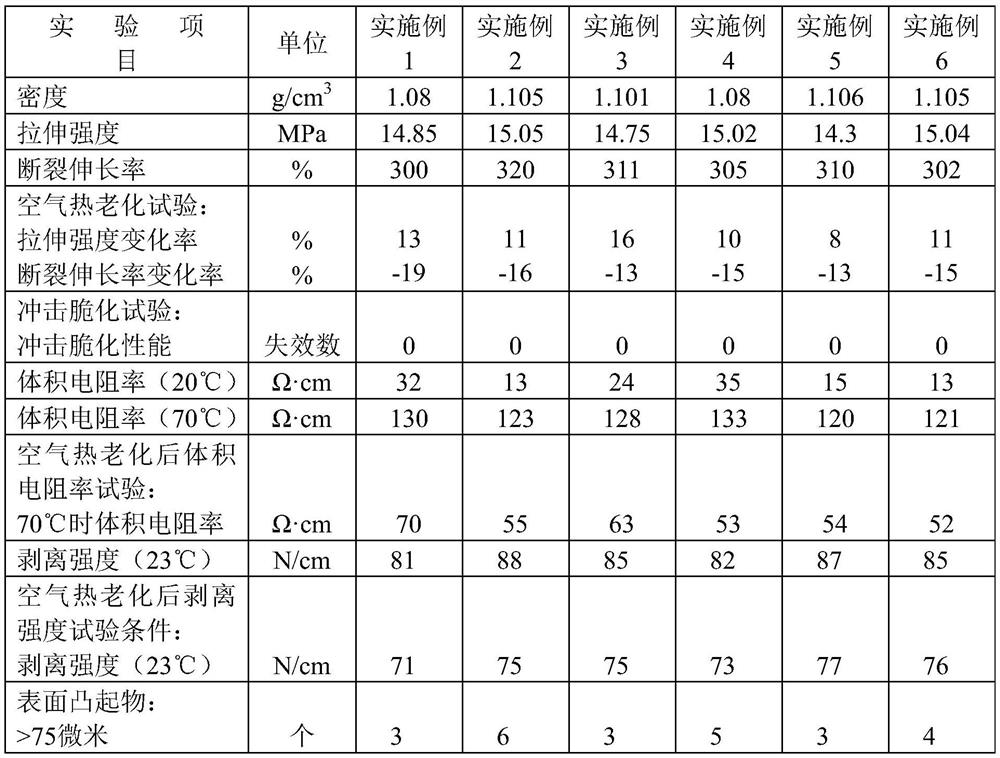

Embodiment 1

[0069] Step 1: Take 1 part of cracked PE wax with a number average molecular weight of 2000-4000, 0.2 part of multifunctional dispersant TEGOdispersers 760W, 0.4 part of antioxidant 4,4'-thiobis(6-tert-butyl-m-cresol ), 2 parts of silicone are added to the mixer for premixing.

[0070] Step 2: Take 12 parts of ethylene-butyl acrylate copolymer, 4 parts of maleic anhydride grafted polyethylene, 49 parts of ethylene-octene copolymer, and 28 parts of Cabot carbon black VXC200, and put them into an internal mixer for closed mixing For 60 seconds, add the pretreated raw materials in step 1, and then close the mixing for 300 seconds again to mix the mature rubber. During the process, the cooling water needs to be turned on to ensure that the temperature of the material is lower than 175°C;

[0071] Step 3: Send the mixed cooked rubber into a single screw for extrusion and granulation. The obtained particles are screened out by a vibrating sieve to screen out irregular particles, the...

Embodiment 2

[0073] The difference between this embodiment and Example 1 is that 14 parts of ethylene-butyl acrylate copolymer, 6 parts of maleic anhydride grafted polyethylene, 53 parts of ethylene-octene copolymer, 30 parts of Cabot carbon black VXC200, and the rest Composition is all identical with embodiment 1. And the preparation process of Example 2 is the same as that of Example 1, and the semi-conductive shielding material is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap